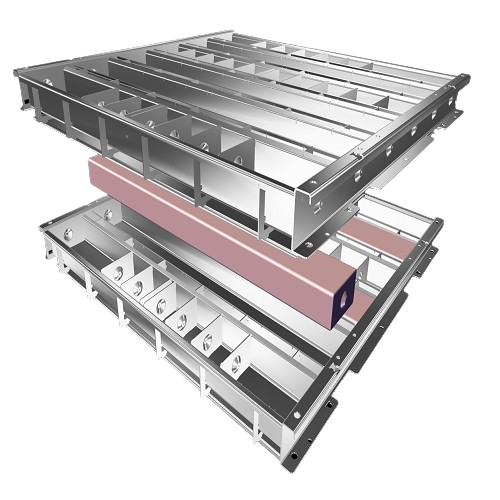

Multimolds for shaped ham logs

Ensure uniformity and precision in shaping, cooking, and chilling ham logs, boosting production capacity by 20-30% with efficient molding and handling, ideal for meeting high-volume demands in ham and deli operations.

Shapes, Cooks, and Chills Ham Products

The Multimolds™ for Shaped Ham Logs by Armor Inox is an innovative solution designed for efficient ham processing. This equipment seamlessly integrates into your production line, offering precise shaping, cooking, and chilling capabilities. Utilizing a patented compact design, it ensures uniform product dimensions and consistent quality throughout each batch. The Multimolds™ system accommodates various ham products, from shaped loaves to deli slices, enhancing versatility and operational efficiency. With optimized loading capacity, you can see improvements of 20 to 30% over traditional systems, minimizing manual handling with automated loading and unloading features. Built from robust stainless steel, it is both durable and easy to maintain, ensuring longevity and reliability in demanding industrial environments. Suitable for food processors and meat producers, it supports both batch and continuous operations, contributing to streamlined production and reduced energy consumption. The system’s compliance with industry standards makes it an ideal choice for producing ready-to-eat meals, deli meats, and more, with configuration options available to meet specific production needs.

Benefits

- Increases production efficiency with up to 30% improved loading capacity.

- Ensures consistent product quality with precise shaping and cooking control.

- Reduces manual labor with automated loading and unloading functionalities.

- Minimizes waste with precise product pressing, guaranteeing uniform end-products.

- Simplifies maintenance and reduces downtime with robust stainless steel construction.

- Applications

- Ready meals, Ham products, Sliced meats, Deli hams, Hot dogs, Shaped ham logs

- End products

- Sliced ham for sandwiches, Deli ham slices, Cooked ham logs, Shaped ham loaves, Ready-to-eat ham meals, Hot dog filler

- Steps before

- Raw Preparation, Slicing, Tumbling, Cooking

- Steps after

- Chilling, Handling, Demolding, Packing

- Input ingredients

- raw ham, delis, logs

- Output ingredients

- shaped ham logs, deli hams, cooked ham, chilled ham, round logs

- Market info

- Armorinox (Middleby) is known for manufacturing custom-engineered stainless steel solutions for industrial applications, particularly in the food processing and commercial kitchen equipment sectors, focusing on quality, durability, and innovation.

- Material

- 100% stainless steel

- Capacity

- Up to 200 metric tons per day

- Automation

- Compatible with automated load, unload solutions

- Consistency Tolerance

- ±2 mm

- Loading Capacity Improvement

- 20 to 30% over traditional systems

- Homogeneity

- Constant product pressing for homogeneous output

- Automation level

- Automatic / Semi-Manual / Manual

- Batch vs. continuous operation

- Batch / Continuous

- Cleaning method

- Easy to clean / CIP

- Compact design

- Space-saving installation

- Product handling versatility

- Logs / Delis / Loafs

- Loading capacity

- Optimized, 20-30% improved

- Homogeneity of product

- Consistency ±2 mm

- Material durability

- 100% Stainless Steel

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High (100% stainless steel)

- Abrasion resistance

- High (Robust design)

- Machine Footprint

- Compact

- Material

- 100% Stainless Steel

- Shape

- Specific for Product Type

- Compatibility

- Traditional, Automated Systems

- Maintenance

- Easy to Maintain, Clean

- Robustness

- High Durability

- Handling

- Automatic, Semi-Manual Options

- Control panel type

- Touchscreen / PLC / HMI

- Integration possibilities

- Compatible with Thermix™ system

- Product dimensions adaptability

- Versatile for logs or deli/loafs

- Material

- 100% stainless steel

- Loading capacity

- Optimized 20-30% more than traditional systems