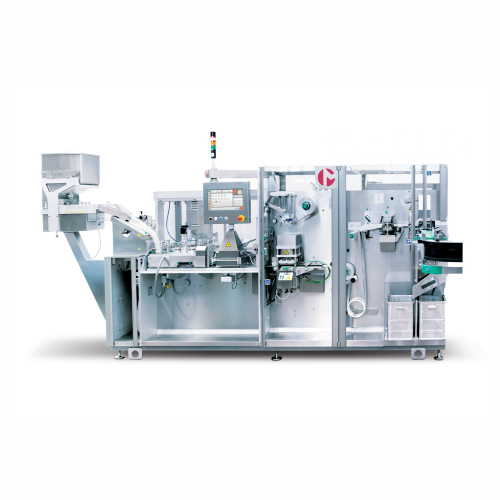

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packaging accuracy and efficiency in high-speed operations.

Forms and Seals Blister Packagings

The MB442 from the Marchesini Group is a high-speed blister thermoforming machine tailored for pharmaceutical and nutraceutical applications. It forms and seals blisters with precision, accommodating a variety of materials like PVC/ALU and others. Specializing in packaging tablets and capsules, it ensures consistent quality and speed, operating at up to 720 blisters per minute. The machine combines intermittent and continuous motion for optimal product handling and sealing. Designed with a balcony structure for enhanced accessibility, it complies with cGMP norms, prioritizing ease of cleaning and maintenance. Mechanical movements operate in an oil bath to minimize wear and extend service life, while its modular design allows for easy size changeovers. Ideal for integrating into existing production lines, it supports varied product shapes, from aspirin tablets to vitamin softgels.

Benefits

- Increases packaging efficiency by handling up to 720 blisters per minute.

- Enhances product quality with precise sealing and reliable material compatibility.

- Simplifies maintenance with a balcony design for easy access and cleaning.

- Reduces operating costs through efficient oil bath mechanics, minimizing wear.

- Ensures compliance with cGMP norms, supporting industry-standard manufacturing processes.

- Applications

- Nutraceuticals, Supplements, Capsules, Pharmaceutical tablets

- End products

- Calcium carbonate tablets, Omega-3 softgels, Vitamin d capsules, Probiotic capsules, Herbal extract capsules, Multivitamin supplements, Aspirin tablets, Effervescent vitamin c tablets

- Steps before

- Material Preparation, Pharmaceutical Ingredient Sorting

- Steps after

- Blister Packing, Quality Inspection, Cartoning

- Input ingredients

- PVC, ALU, ALU/ALU, Polypropylene, PET, PVC + Aclar, COC, capsules, tablets, oblongs

- Output ingredients

- blisters

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Forming Width

- 150 mm to 290 mm

- Forming Depth

- 9 mm to 12 mm

- Production Speed

- 220 to 720 blisters/min

- Material Compatibility

- PVC/ALU, ALU/ALU, Polypropylene, PET, PVC + Aclar®, COC

- Motion Type

- Intermittent for forming, coding, and cutting

- Continuous for loading and sealing

- Sealing Method

- Seals lid material onto cavities

- Working mechanism

- Intermittent motion for forming, continuous motion for loading and sealing

- Automation level

- PLC-controlled

- Product loading

- Separated from lidding/sealing area

- Changeover time

- Easy size changeover

- Cleaning method

- Balcony design for accessibility and maintenance

- Batch vs. continuous operation

- Intermittent for forming, continuous for loading

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact balcony design

- Feed/Discharge method

- Intermittent motion for coding and cutting

- Continuous motion for loading and sealing

- Forming width

- 150 mm to 290 mm

- Forming depth

- 9 mm to 12 mm

- Blister Production Speed

- 220 to 720 blisters/min

- Control panel type

- Intuitive with accessibility in mind

- Discharge method

- Blisters are discharged onto the outfeed conveyor

- Control Panel Type

- Customizable HMI

- Integration Possibilities

- Compatible with various forming/lidding materials (e.g., ALU/ALU, Polypropylene, PVC + Aclar®, COC)

- Forming Width Range

- 150 mm to 290 mm

- Forming Depth Range

- 9 mm to 12 mm

- Production Speed

- 220 to 720 blisters/min