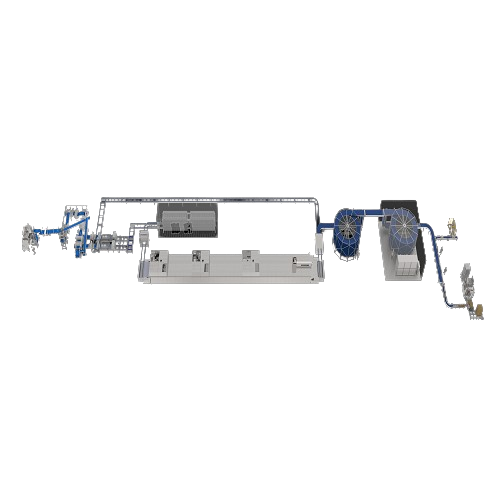

High-speed baguette production system

Achieve seamless, high-speed production of artisan baguettes with minimal downtime and rapid changeovers, ensuring consistent quality and flexibility for expanding product lines.

Produces Artisan and Soft Bread Varieties

The Baguette Line by AMF Bakery Systems revolutionizes high-speed production for artisan-style bread. This adaptable system features modular integration, enabling seamless product changeovers and maximum variety. Utilizing advanced sheeting and proofing technologies, it produces up to 8,400 baguettes per hour while supporting multiple bread varieties, including sourdough and ciabatta.

Its operation is streamlined with AMFConnect™, which offers real-time data monitoring for improved decision-making and operational efficiency. The system is equipped with energy-efficient components, such as the Intralox ThermoDrive® conveyor for contamination prevention and an optimized motor for reduced energy consumption.

The line is designed with hygiene in mind, featuring toolless removal for cleaning and a wash-down capable design for sanitary operations. Constructed with durable materials to handle high-capacity operations, this production line suits both commercial and industrial bakeries. Fully customizable, AMF offers engineering support to tailor the system to specific production needs, ensuring compliance with industry standards and enhancing your bakery’s capabilities.

Benefits

- Enhances production capacity with the ability to produce up to 8,400 baguettes per hour.

- Reduces operational costs through streamlined product changeovers and minimal downtime.

- Improves product quality and consistency with real-time data monitoring via AMFConnect™.

- Ensures rigorous sanitation standards with easy-to-clean, wash-down-ready modular design.

- Offers flexibility in bread variety production, catering to diverse market demands easily.

- Applications

- Buns, Flatbreads, Artisan rolls, Pizza, Pies, Tin bread, Soft bread, Cakes, Pastries, Croissants, Baguette, Swirl bread, Artisan bread

- End products

- Blueberry pie, Brioche loaves, Viennese bread, Pizza crusts, Pita bread, Ciabatta rolls, Almond croissants, Chocolate croissants, Traditional baguettes, Vanilla sponge cake, Sandwich bread, Chocolate fudge cake, Panini rolls, Cinnamon swirl bread, Hot dog buns, Rustic sourdough baguettes, Raisin bread, Apple pie, French artisan baguettes, Hamburger buns, Focaccia

- Steps before

- Dough Mixing, Dough Chunking, Dough Elevation

- Steps after

- Proofing, Baking, Cooling, Freezing, Handling, Decorating, Packaging

- Input ingredients

- raw dough, flour, water, yeast, salt

- Output ingredients

- artisan baguettes, high-quality baguettes

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Production Speed

- Up to 8, 400 baguettes per hour

- Capacity

- 30, 000 lbs/hour (Raw Dough Conveyor)

- Automation

- Integrated, real-time bakery system data (AMFConnect™)

- Changeover time

- Rapid Changeovers

- Sanitary Design

- Zero pretension for gentle handling

- Mixing Adaptability

- Various dough types

- Conveyor System

- Intralox ThermoDrive®

- Handling

- Gentle handling to maintain dough integrity

- Cooling System

- Vesta Spiral Cooler with full wash-down sanitation

- Footprint

- Small footprint design (Den Boer Depanner)

- Product Flexibility

- Wide range of artisan products

- Installation,Maintenance

- Patented design (Vesta Spiral Cooler)

- Conveyor Applications

- Custom configured with vertical belt support rails

- Automation level

- PLC / SCADA

- Changeover time

- Rapid

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Full wash-down sanitation

- CIP/SIP

- Seamless integration

- Energy efficiency

- Optimized

- Abrasion resistance

- Yes

- Biological compatibility

- Food grade materials

- Cleanability

- Full wash-down capable

- Modular Units

- Yes

- Footprint Design

- Small footprint

- Flexibility

- High

- Belt Configuration

- Vertical Belt Support Rails

- Control Panel Type

- AMFConnect™ Integrated System

- Installation Design

- Patented Spiral Cooler Design

- Discharge Method

- Toolless Removal

- Integration

- Seamless into Artisan Dough Systems

- Control panel type

- AMFConnect™

- Integration possibilities

- Modular units for easy product changeover

- Discharge method

- Toolless removal of components