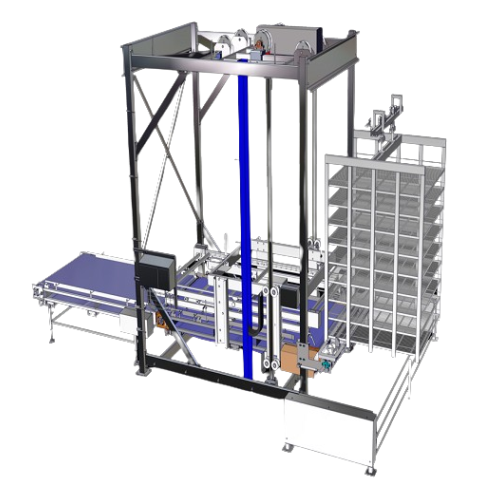

Rack log loader for ready-to-eat products

Efficiently streamline your loading and handling operations with a system designed for precise molding and demolding, ensuring consistent quality for ready-to-eat meals.

Automates Loading and Handling of Food Products

The RTE Rack Log Loader from Armor Inox is a pivotal solution for automating the loading and handling processes in food production lines, particularly for ready-to-eat meals, hams, and delis. This equipment integrates seamlessly with your existing systems, using advanced automation to reduce manual intervention and improve cycle times. It supports various operations including manual, semi-manual, and fully automatic modes, tailored to meet the diverse needs of food processing environments. This loader is ideal for managing solid product types such as vacuum-sealed sous vide, frozen meal components, and packaged meat. Constructed with durable materials for enhanced corrosion resistance, it is compliant with food industry standards. Armor Inox provides engineering support to customize the loader’s configurations, ensuring optimal performance for your specific manufacturing needs.

Benefits

- Enhances operational efficiency by minimizing manual handling efforts.

- Increases production throughput with streamlined loading processes.

- Reduces labor costs through its automated handling capabilities.

- Complies with food safety standards, ensuring product quality and consistency.

- Customizable configurations accommodate diverse product types and processing needs.

- Applications

- Ready meals, Sous vide, Delis, Hams, Hot dogs

- End products

- Sliced turkey breast deli, Vacuum-sealed sous vide chicken breast, Honey-glazed spiral ham, Cocktail frankfurters, Frozen beef bourguignon meal

- Steps before

- Raw Preparation, Tumbler Bamix™, Jelly Tank Gelix™, Cooking VAT Chaudix™, Multimolds™, Semi-Manual Molding, Automatic Molding

- Steps after

- Semi-Manual Demolding, Automatic Demolding, Batch Immersion Cook, Chill, Continuous Cook, Chill, Camatix Pasteurization

- Input ingredients

- Output ingredients

- Market info

- Armorinox (Middleby) is known for manufacturing custom-engineered stainless steel solutions for industrial applications, particularly in the food processing and commercial kitchen equipment sectors, focusing on quality, durability, and innovation.

- Automation

- Automatic

- Batch vs. continuous

- Automatic

- Capacity

- N/A

- Operating modes

- Manual / Semi-Manual / Automatic

- Material Compatibility

- Stainless Steel

- Temperature Range

- N/A

- Energy Usage per Batch

- N/A

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture