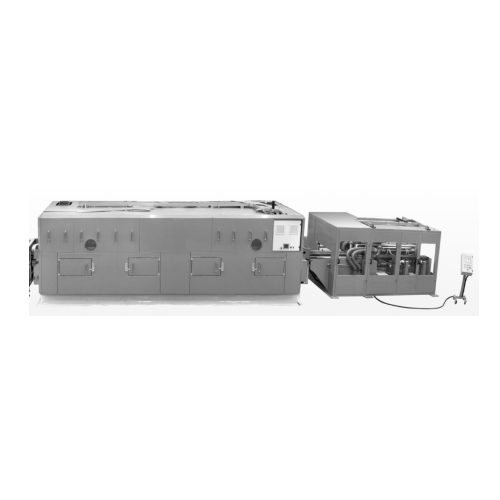

Industrial grid gravity casting system

For manufacturers seeking precise metal casting, this equipment ensures consistent quality in battery grids and metal components through efficient gravity casting processes.

Casts and Molds Battery Grids and Metal Parts

The Industrial Grid Gravity Casting Machine from Sovema Group is engineered to enhance the precision casting of battery grids and metal components. Leveraging gravity casting principles, it efficiently processes lead-acid battery grids, automotive battery grids, marine battery grids, metal casings, and machine components. Ideal for battery and metal industries, this machine supports high-volume production with consistent output quality. With features such as PLC-controlled automation and seamless integration into existing production lines, it ensures reduced downtime and increased throughput. Designed with energy efficiency in mind, the machine boasts optimized motor control. Available in durable materials, it resists wear from molten metals, ensuring longevity and reliability in harsh industrial environments. Additional customization options allow tailoring to specific operational needs, supported by Sovema Group’s engineering expertise.

Benefits

- Enhances production efficiency with precision gravity casting for diverse battery grids and metal components.

- Increases operational reliability by integrating seamlessly into existing processing lines with minimal downtime.

- Reduces energy costs through optimized motor control, ensuring sustainable production.

- Offers long-term durability with material options resistant to high-temperature and corrosive environments.

- Customizable configurations meet specific production requirements, backed by expert engineering support.

- Applications

- Industrial equipment, Batteries, Metal casting

- End products

- Lead-acid batteries, Machine components, Marine battery grids, Industrial battery grids, Structural metal parts, Metal casings, Automotive battery grids

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Working mechanism

- Gravity casting

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Footprint

- N/A

- Cast method

- Gravity

- Control system

- N/A