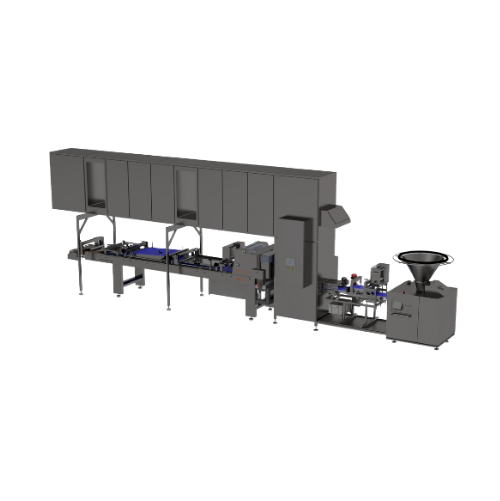

Automatic baguette production system

Efficiently shape and perfect long, oblong bread varieties with high consistency and minimal stress, ensuring artisanal quality and appearance in every loaf produced.

Produces Artisan Bread in Automated Lines

The Baguetta Bread Line from WP Haton is an automated solution for artisan and industrial bakeries focused on producing high-quality oblong bread products. This fully automatic system is designed to handle the entire production process—from dividing to proofing and moulding—ensuring consistent quality and artisan appearance. The Baguetta line achieves this with its dough-friendly dividers and advanced dough handling techniques, which maintain minimal stress during moulding. With up to 6,000 dough pieces per hour capacity, it caters to high-demand settings while ensuring optimal dough development through integrated resting times. The Baguetta line efficiently accommodates various applications, producing baguettes, ciabatta, and other Mediterranean breads without compromising on structure or taste. Configurable options for dough weight range and a built-in continuous operation feature make it a versatile addition to any automated bakery setup.

Benefits

- Ensures consistent artisan-quality bread with automated precision.

- Enhances dough development, optimizing elasticity and stretchability.

- Increases production output with a capacity of up to 6,000 pieces per hour.

- Minimizes dough stress for superior texture and taste.

- Seamlessly integrates into existing production lines for efficient operation.

- Applications

- Baguettes, Toast bread, Mediterranean bread, Bakery products, Brioches, Ciabatta

- End products

- Fougasse, Ciabatta loaves, French breadsticks, Toast bread slices, Panini bread, Brioche buns

- Steps before

- Dough preparation, Ingredient mixing, Dough resting

- Steps after

- Baking, Cooling, Packaging

- Input ingredients

- dough, dough pieces

- Output ingredients

- baguettes, brioches, toast bread, ciabatta, Mediterranean bread

- Market info

- WP Haton is known for producing high-quality, industrial dough processing equipment. They specialize in designing and manufacturing custom engineered-to-order solutions for the baking industry, with a strong reputation for innovation, reliability, and customer service.

- Automation

- Fully automatic

- Capacity

- Up to 6, 000 pcs/h

- Dough weight range

- 100 - 750 gr

- Output

- Up to 6, 000 dough pieces per hour

- Product Type

- Baguettes, brioches, toast bread

- Accuracy

- Portioning done very accurately

- Moulding process

- Rectangular dough pieces stretched to length

- Dough development

- Optimal dough development with minimal stress

- Working mechanism

- Automatic make up system

- Integrated steps

- Dividing, rounding, proofing, moulding

- Batch vs continuous operation

- Continuous

- Automation level

- Fully automatic

- Capacity

- Up to 6, 000 pcs/h

- Output consistency

- High degree

- Dough development

- Optimal due to continuous movement

- Compatible dough types

- Baguette, ciabatta, Mediterranean-style breads

- Shape requirements

- Oblong shape

- Dough weight range

- 100 - 750 gr

- Production capacity

- Up to 6, 000 pieces per hour

- Feed method

- Fully automatic

- Discharge method

- Final shaping to desired oblong shape

- Bread shape

- Oblong (e.g., baguette, ciabatta)

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- Seamless integration with existing bakery systems

- HMI type

- Intuitive user interface

- Modular configuration

- Scalable to various production sizes

- Product type compatibility

- Baguettes, ciabatta, brioche, toast bread

- Output capacity

- Adjustable up to 6, 000 pcs/h

- Dough weight range

- 100 - 750 grams

- Automation level

- Fully automatic

- Moulding customization

- Length and shape adjustments