Sweets Moulding Equipment

Find production technology for moulding sweets, and connect directly with leading machine manufacturers worldwide.

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Which sweets moulding technology do you need?

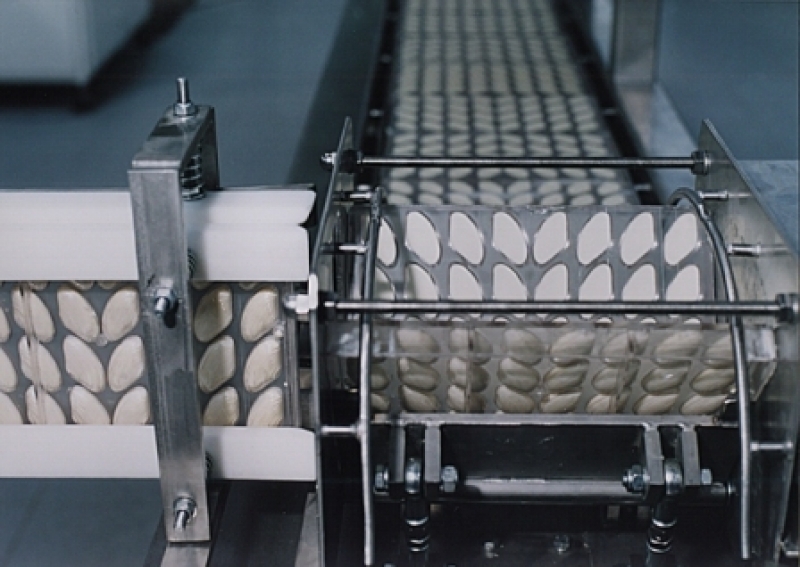

Rotary molder for softdough biscuits and shortbreads

For high output bakeries, achieve precise dough piece formation and ...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

Figure moulding for pliable mixes

Transform pliable mixtures into intricate 3D figures with precision and efficiency, cater...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

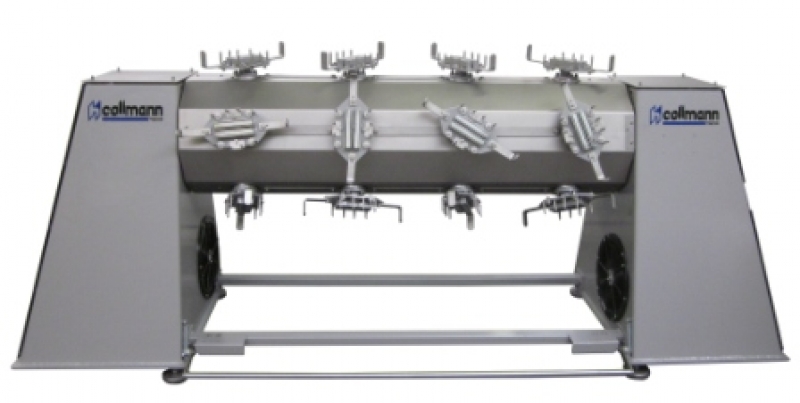

Double spinning machine for hollow chocolate figures

Achieve perfect distribution of chocolate in molds with precision sp...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Hollow chocolate figure spinning solution

Achieve uniform chocolate coating in hollow figurines with precision spinning te...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Pastry depositor for versatile product shapes

Enhance your bakery’s production with a versatile depositor that effor...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

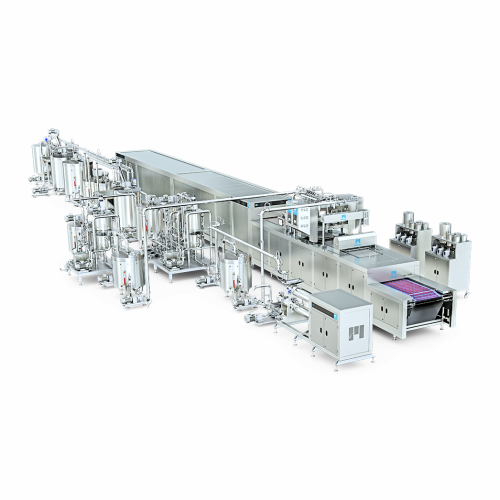

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

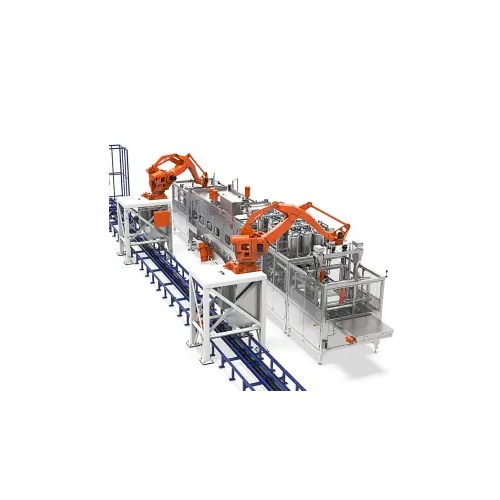

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Rotationally symmetric product rolling machine

Achieve precision shaping of chocolate balls, candy drops, and more with ou...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy manufacturing system

Efficiently streamline your candy production with a system capable of producing up to ...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

Pilot plant for ice cream production

Optimize your ice cream production with a flexible pilot plant that seamlessly integra...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Industrial manju cake production system

Transform traditional treats into innovative 3D cakes with precise filling and perf...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

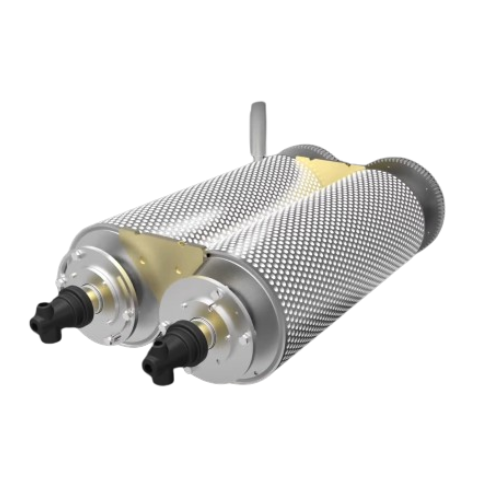

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

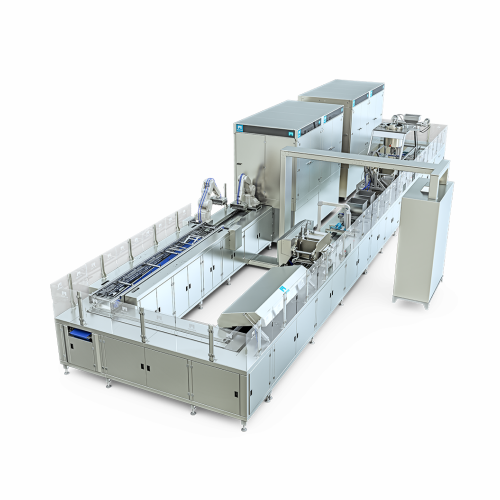

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

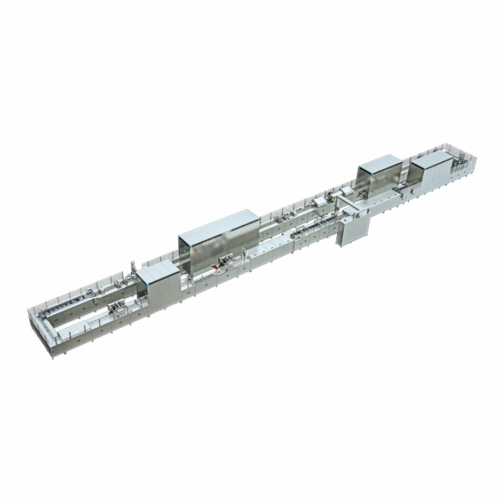

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

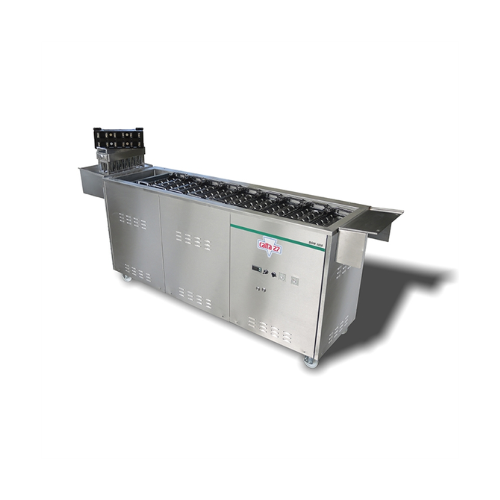

Commercial ice popsicle making solution

Optimize your frozen dessert production with a versatile machine capable of craftin...

Polvoron and mung bean cake moulding system

Efficiently mold and shape your confectionery creations with this versatile sy...

Commercial delimanjoo and taiyaki custard cake maker

Enhance your pastry production with high-speed, mold-customizable ca...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Chocolate truffle extruder

Achieve precise and versatile production of chocolate truffles and snacks, with seamless integrat...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

Semi-automatic dough sheeter

There is a wide range of commercial dough sheeters available, many of which are purpose-built f...

Automatic bread dough sheeter

Dough for speciality breads must first be rolled into sheets of varying thickness, to facilita...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Compact 4-arm spinner for chocolate

For small productions or lab use in the manufacturing of chocolate hollow figures.

Big scale chocolate spinner

For larger production capacities of chocolate hollow figures.

Automatic book-moulding system

Closes ‘book-moulds’ in order to produce eggs, balls, sea shells, and other 3-dim...

Semi-automatic moulding line for solid chocolates

Perfect for scaling up your production of tablets or filled chocolates.

Moulding line for pralines, tablets and cups

To automatize the process of moulding pralines, tablets, and cups in artisan ...

Horizontal cooling tunnels for chocolate moulds

The perfect tunnel for semi-automatic production lines.

Starch-free depositor systems for jelly

Traditional depositing for jellies and gummies requires the use of starch moulds. T...

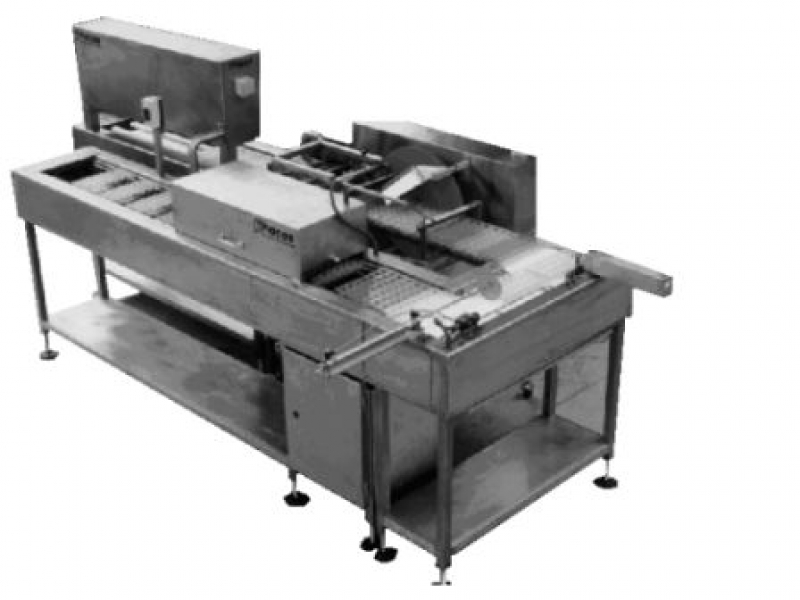

Starch-free depositor for soft confectionery

Soft confectionery such as toffees, fondants, fudges and jellies have traditi...

Starch-free depositor for lollipops

Traditional high volume continuous lollipop production can lead to inconsistent product...

Starch-free depositor for hard candy

Forming hard candies requires careful handling of syrups in order to avoid quality iss...