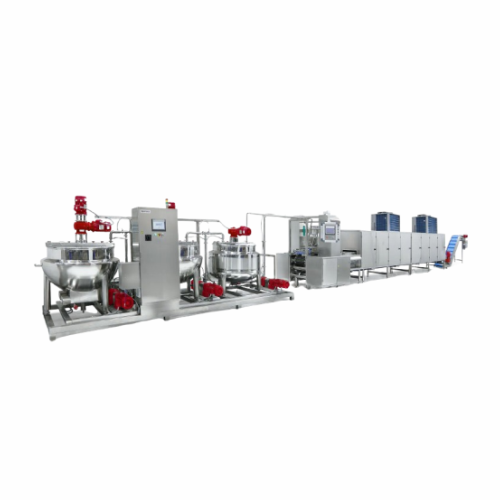

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small to medium production runs, efficiently handling both single and dual-color varieties for diverse product lines.

Deposits and Colors Gummies Efficiently

The GT600 Gummy Production System by GummyTech is a versatile solution that offers flexibility for both batch and semi-continuous gummy production, making it ideal for small to medium confectionery and nutraceutical facilities. With depositor speeds reaching up to 60,000 gummies per hour, this equipment effectively handles product variations, including dual-colored gummies. The system integrates seamlessly into existing production lines, supporting efficient deposition and coloring processes for diverse gummy formulations, such as fruit-flavored gummies, vitamin supplements, and herbal-infused products.

Engineered to meet the evolving demands of food, confectionery, and nutraceutical industries, the GT600 operates on a flexible power supply of either 220V or 480V, and fits compactly with dimensions of 53L x 7W x 9H feet, accommodating various factory layouts. The robust system, approximately 7500 kg in weight, ensures durability and stability during high-speed operations.

Hygiene and ease of maintenance are prioritized through its design, which is compatible with standard cleaning protocols, ensuring efficient cleanup between production runs. The GT600 supports automated operations with advanced depositors that enhance productivity and consistency, while responding to diverse customer needs with customizable options tailored for specific production requirements. Whether you’re introducing new product lines or scaling up, this system is equipped to support the dynamic needs of confectionery and nutraceutical production.

Benefits

- Increases production efficiency with depositor speeds up to 60,000 gummies per hour.

- Enhances product diversity with capability for dual-colored gummy production.

- Supports flexible production demands with both batch and semi-continuous operations.

- Optimizes factory space with compact system dimensions for easy integration.

- Eases maintenance and cleanup, ensuring quick transitions between production runs.

- Applications

- Supplements, Nutraceuticals, Gummies, Sweets, Gummies with two colors

- End products

- Probiotic gummies, Collagen gummies, Herbal supplement gummies, Vitamin c gummies, Fruit-flavored gummies, Zinc lozenges, Two-colored multivitamin gummies, Omega-3 gummy supplements, Children's chewable vitamins

- Steps before

- Ingredient preparation, Batch mixing, Color mixing

- Steps after

- Gummy drying, Quality assurance, Packaging, Labeling

- Input ingredients

- Output ingredients

- Market info

- Automation

- Automatic

- Batch vs. continuous

- Batch or Semi-continuous

- Depositor Speed

- Up to 60, 000 gummies/hour

- Production Capacity

- Small to medium production runs

- Power

- 220V/3PH/60HZ or 480V/3PH/60HZ

- System Dimensions

- 53L x 7W x 9H (ft)

- Gross Weight

- Approx. 7500 Kg

- Color Capability

- One or two colors

- Batch vs. continuous operation

- Batch / Semi-continuous

- Production rate

- 60, 000 gummies per hour

- Color production capability

- One or two colors

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 53L x 7W x 9H (ft)

- Gross Weight

- Approx. 7500 kg

- Production capacity

- Up to 60, 000 gummies per hour

- Production mode

- Batch or Semi-continuous

- Color options

- One or Two Colors

- System power supply

- 220V/3PH/60HZ or 480V/3PH/60HZ

- Capacity (production speed)

- Up to 60, 000 gummies per hour

- Dimensions

- 53L x 7W x 9H (ft)

- Gross weight

- Approx. 7500 kg