High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure precision, efficiency, and versatility, enabling you to craft diverse sweets from gummies to hard candies, effortlessly meeting complex product specifications and high-quality standards.

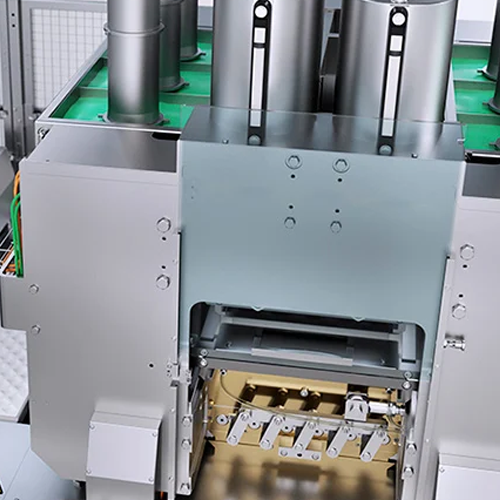

Deposits and Shapes Confectionery Products

The Makat HLM 35 RS Mogul Line from Syntegon’s Makat brand offers a robust solution for confectionery manufacturers navigating the demands of complex product depositing and shaping. This equipment is distinguished by its precise servo-driven chainless tray transport system, ensuring smooth handling and minimal wear. Designed for a variety of applications, it efficiently processes gummies, jellies, toffees, and hard candies with high accuracy and flexibility. With a throughput of up to 6,000 kilograms per hour, the system integrates seamlessly into existing production lines, featuring automated controls and real-time monitoring for enhanced productivity. The Makat HLM 35 RS is constructed from durable materials to withstand demanding operational conditions, offering energy-efficient operation with optional energy recovery systems and reducing steam and cooling water requirements. It complies with food safety standards, facilitating hygienic production with easy-to-clean components. Additionally, this equipment can be customized with various depositing options and sizes, supported by expert engineering services to ensure optimal performance tailored to specific production requirements.

Benefits

- Ensures product consistency with precise and reproducible depositing results.

- Boosts production efficiency by integrating seamless automation and minimizing manual intervention.

- Lowers energy costs through innovative energy recovery systems.

- Facilitates quick cleaning and maintenance, reducing operational downtime.

- Offers flexibility to accommodate diverse confectionery formulations and production demands.

- Applications

- Jellies, Nutraceuticals, Confectionery, Caramels, Gummies, Toffees, Sweets, Hard candy, Fondants

- End products

- Gummy vitamins, Double-layer fondants, Double-layer toffees, Aerated marshmallow sweets, Center-filled jellies, Caramel chews, Starlight hard candies, Healthy nutraceutical jellies, Starchless deposited gummies, Multi-colored jellies

- Steps before

- Ingredient preparation, Slurry preparation, Dissolving and cooking, Coloring and flavoring, Aerating

- Steps after

- Oiling, Sugar sanding, Packaging

- Input ingredients

- gelling agents, raw materials, liquid ingredients, dry ingredients, color, flavor, acid, foam sugar masses

- Output ingredients

- gummies, jellies, toffees, caramels, fondants, hard candies, confectionery sweets, functional sweets, nutraceutical gummies, nutraceutical jellies, nutraceutical hard candies

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Capacity

- Up to 6, 000 kg/h

- Accuracy

- Precise dosing with weighing cells

- Automation

- PLC-controlled processes

- Cooling temperature

- Adjustable through integrated cooling unit

- Dosing type

- Gravimetric and volumetric

- Mixing method

- Double-X mixer, bubble-free mixing

- Energy efficiency

- Energy Recovery System for steam and cool water reduction

- Drying system

- Whirl layer system for starch drying and cooling

- Cycle time

- Batchwise and continuous production possible

- Finishing process

- Oil polishing and sugar sanding options

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- Low energy consumption

- Cleaning method

- CIP / Manual

- Changeover time

- Quick changeover capabilities

- Air incorporation control

- Precise control for texture

- Integrated process steps

- Ingredient preparation to finished product

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Foaming

- Yes/No

- Agglomeration Risk

- High/Low

- Tank shape

- Cylindrical / Conical

- Tank size

- Variable based on capacity needs

- Feed method

- Automated / manual

- Discharge method

- Gravity / pumped

- Control panel type

- Touchscreen / analog

- Control panel type

- Touchscreen HMI

- Integration possibilities

- SCADA / PLC integration

- Discharge method

- Automated / Manual

- Customization for different mass viscosities

- Adjustable to product type

- System configuration options

- Modular design for adaptability

- Recipe management

- Customizable with precise control