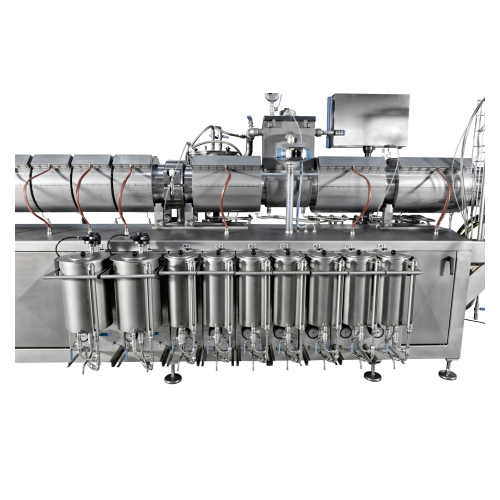

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and acid with advanced control systems, ensuring consistent product taste while optimizing high-cost ingredient usage.

Accurately Doses Liquids in Continuous Production

Extrufood’s precision dosing skids are engineered for seamless integration with continuous extrusion lines across confectionery, pet food, and plastics industries. These skids utilize high-quality components and advanced controls to precisely dose liquids like colors, flavors, and acids, ensuring consistent product quality. Key technologies include highly accurate flow meters and loss-in-weight systems, crucial for managing high-cost additives. Designed with flexibility, the dosing pumps and tanks can be mounted on the main extruder frame or a separate mobile skid, catering to various production environments. This equipment efficiently handles liquid dosing with a focus on cost control and precision, making it indispensable for manufacturing gummy candies, flavored jellies, pet treats, and more. Available in durable materials suitable for food-grade applications, Extrufood ensures that their solutions can withstand the demands of high-precision, continuous operations.

Benefits

- Ensures consistent product quality by delivering precise liquid dosing.

- Minimizes additive costs through highly accurate dosing technology.

- Offers flexible integration with existing extrusion lines, reducing installation time.

- Supports high-efficiency production with continuous operation.

- Customizable setup options accommodate diverse production environments.

- Applications

- Snacks, Pet food, Confectionery, Sweets, Plastics

- End products

- Pet treats, Food-grade plastic pellets, Flavored snacks, Extruded licorice, Gummy candies, Caramel chews, Sugar-coated sweets, Biodegradable plastic components, Dental chews for pets, Flavored jellies

- Steps before

- Ingredient Mixing, Material Preparation

- Steps after

- Cooling, Cutting, Packing

- Input ingredients

- color, flavor, acid

- Output ingredients

- consistent flavor product

- Market info

- Extrufood is known for manufacturing custom-engineered food extrusion equipment, particularly in the confectionery sector. They excel in designing machinery tailored to specific client needs, emphasizing innovation, quality, and efficiency in the production process.

- Accuracy

- Highly accurate, supported by feedback systems like flow meters

- Dosing type

- Manual / Auto dosing

- Flow meter type

- Highly accurate flow meters / Loss in weight systems

- Placement

- Main extruder frame / Movable skid

- Component control

- Individually controlled

- Flavor dosage control

- Consistent flavor assurance

- Accuracy in dosage

- High precision

- Automation level

- PLC-controlled

- Dosing method

- Loss in weight systems

- Flexibility

- Fixed or movable skid

- Component control

- Individually controlled components

- Flow control

- Feedback systems

- Placement options

- Main extruder frame or separate skid

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Yes

- Control panel type

- Advanced controls