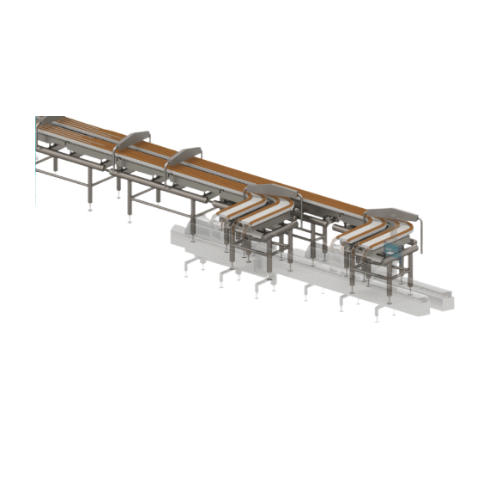

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and maintaining continuous product flow with this advanced vibratory buffering solution, ensuring consistent processing in high-speed environments.

Buffers and Manages Product Flow Efficiently

The Vibratory Buffer from Royal Houdijk revolutionizes buffering and product flow management in the food, manufacturing, and packaging industries. This system is equipped with Houdijk’s proprietary technology, featuring a single drive per section and amplitude feedback to ensure a consistent and controlled flow of products like potato chips, chocolate candies, and granola bars. Dynamically speed-controlled via integrated level sensors, it maintains uninterrupted flow and precise product back pressure management, making it ideal for high-speed, continuous operations. With options for automatic discharge of misaligned products and tool-free track changeovers, it offers minimal maintenance and swift recipe transitions, ensuring seamless integration into your production line.

Benefits

- Enhances line efficiency by absorbing downstream stoppages seamlessly.

- Offers precise control over product flow, reducing product damage.

- Minimizes maintenance needs with easy tuning and swift changeovers.

- Ensures continuous operation with automated removal of misaligned products.

- Integrates effortlessly into existing systems with tool-free track changeovers.

- Applications

- Cereals, Sweets, Snacks

- End products

- Gummy bears, Cornflakes, Granola bars, Potato chips, Chocolate candies

- Steps before

- Product Conveying, Sorting, Feeding

- Steps after

- Downstream Loading, Packaging, Quality Control

- Input ingredients

- Output ingredients

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Drive System

- Single drive per section

- Control System

- Integrated control with amplitude feedback

- Speed Control

- Dynamically speed controlled

- Level Sensors

- Positioned over each lane

- Product Flow Control

- Consistent and controlled

- Maintenance

- Minimal

- Recipe Changeover

- Swift

- Automation

- Automatic product discharge capability

- Changeover Method

- Tool-free changeover option

- Working mechanism

- Vibratory system

- Integrated steps

- Amplitude feedback

- Flow control

- Dynamically speed controlled

- Product flow

- Consistent and controlled

- Changeover type

- Tool-free

- Automation level

- Integrated control system

- Maintenance requirement

- Minimal maintenance

- Product discharge

- Automatic discharge

- Control system

- Integrated control system

- Abrasion resistance

- Compatible with continuous product flow

- Biological compatibility

- Suitable for food products such as bakery goods

- Cleanability

- Features minimal maintenance for easy cleaning

- Corrosive resistance (e.g. acids)

- Resistance to food processing ingredients

- Density/particle size

- Suitable for stacked products and uniform control

- Batch vs. continuous

- Continuous flow

- Discharge method

- Automatic discharge for misplaced products lying flat or standing

- Changeover

- Tool-free track changeover

- Footprint

- Compact due to integrated control system

- Amplitude feedback control

- Yes

- Dynamic speed control

- Yes

- Integrated control system

- Yes

- Level sensors

- Yes

- Automatic product discharge

- Yes

- Tool-free track changeover

- Optional