Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensuring that only defect-free products move forward, minimizing stoppages and manual interventions with advanced vision inspection technology.

Inspects and Rejects Defective Products

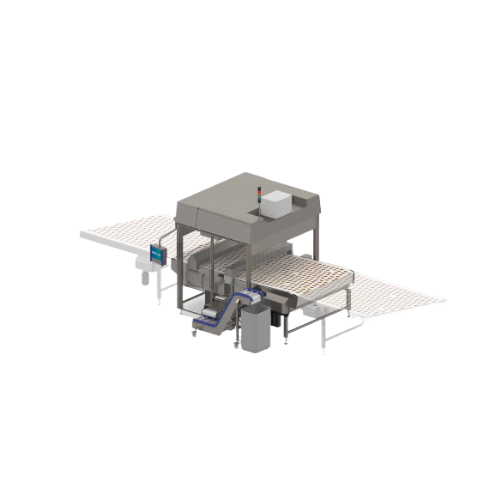

The Vision Selector from Royal Houdijk is a cutting-edge product inspection and rejection system designed for high-speed, continuous operations in the food, manufacturing, and packaging industries. Utilizing an array of cameras, it inspects products like potato chips, gummy candy, and granola bars for circumference, height, shape, and position to detect defects. Capable of rejecting individual products, it safeguards downstream equipment from stoppages and waste. With the ability to share quality data with your MES system, it supports enhanced quality control and operational efficiency. This system can be configured to integrate additional inspections, such as color and surface quality, according to your specifications. Engineered for seamless integration, the Vision Selector optimizes your production line while minimizing manual interventions.

Benefits

- Enhances production efficiency by preventing downstream stoppages.

- Reduces manual intervention through automated defect rejection.

- Integrates seamlessly with your MES for real-time quality data sharing.

- Supports customizable inspection parameters to meet specific quality control needs.

- Preserves product quality and consistency, protecting brand reputation.

- Applications

- Cereals, Sweets, Pet food, Snacks

- End products

- Granola bars, Gummy candy, Dog kibble, Potato chips, Corn flakes, Cat treats

- Steps before

- Product Sorting, Alignment, Guiding

- Steps after

- Data Analysis, Manual Inspection, Packing

- Input ingredients

- products, materials, goods

- Output ingredients

- inspected products, rejected products, qualified products, disqualified products

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Inspection Type

- Vision

- Inspection Parameters

- Circumference, Height, Shape, Position

- Rejection System

- Individual Product Reject Unit

- Data Integration

- MES System

- Additional Quality Control

- Color, Surface (Customer Specifications)

- Product inspection system

- Camera-based

- Inspection parameters

- Circumference, height, shape, position

- Rejection mechanism

- Individual product reject unit

- Data integration

- Compatible with MES

- Automation level

- Automated inspection

- Additional quality control

- Customizable (e.g. color, surface)

- Batch vs. continuous operation

- Inline Continuous

- Discharge method

- Individual product reject unit

- Integration with MES

- Yes

- Camera Array Configuration

- Based on product specifications

- Additional Quality Control Features

- Color, surface inspection