Gum slabs flow wrapping solution

Streamline your confectionery production with precision-engineered portioning and wrapping, designed for seamless high-speed operations and consistent product quality.

Portions and Wraps Square Chewing Gum Slabs

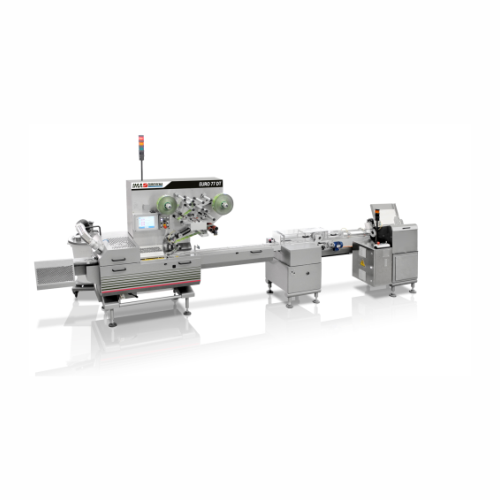

The EURO 77 DT from IMA Group is a specialized flow wrapping machine designed to precisely portion and wrap square-shaped chewing gum slabs. It integrates seamlessly into confectionery production lines, utilizing in-house engineered handling and portioning units to streamline operations. Its compact design incorporates a vertical loader, rotary pre-scoring unit, and timing conveyor to ensure continuous, high-speed processing. Capable of handling varying sizes, it offers flexibility with multiple counting units for efficient box filling. The system is PLC-controlled, optimizing both operation and maintenance, enhancing energy efficiency, and ensuring compatibility with existing automation solutions. Constructed with hygienic materials and a robust design, it supports easy cleaning to minimize downtime. Ideal for confectionery and food industries, the EURO 77 DT promises high throughput and consistent packaging quality.

Benefits

- Enhances productivity with high-speed, continuous wrapping for square chewing gum slabs.

- Minimizes labor costs through integrated portioning and automated flow wrapping.

- Reduces energy usage with an optimized 7.5 kW motor.

- Offers flexibility in production with adjustable sizing for diverse product configurations.

- Streamlines cleaning and maintenance with its compact, hygienic design.

- Applications

- Sweets, Confectionery, Chewing gum

- End products

- Individually packaged sweets, Square-shaped chewing gum slabs, Wrapped candy pieces

- Steps before

- Gum slab production, Forming square shaped gum slabs

- Steps after

- Box filling, Packaging, Distribution

- Input ingredients

- square shaped gum slabs

- Output ingredients

- wrapped gum slabs, wrapped square shaped gum slabs

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Product Size Range - Length

- 30-480 mm

- Product Size Range - Width

- 30-37 mm

- Product Size Range - Thickness

- 1-4 mm

- Film Reel Inner Diameter

- 70-76 mm

- Film Reel External Diameter

- Up to 380 mm

- Film Reel Width

- Up to 200 mm

- Electrical Data

- 7.5 kW

- Air Pressure

- 0.6 – 0.9 MPa

- Air Consumption

- 10 NI/min

- Integration and Synchronisation

- Portioning and Flow Wrapping

- Compact Footprint

- Yes

- Multiple Counting Units

- Available for Box Filling

- Working mechanism

- Integrated flow wrapping and portioning

- Automation level

- Highly automatic with integrated systems

- Changeover time

- Quick changeover due to modular design

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Hygienic design for easy cleaning

- Portioning and wrapping integration

- Synchronized systems

- Compact footprint

- Space-saving design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Shape

- Square

- Product Type

- Gum slabs

- Product size range

- Length

- Film reel dimensions

- Inner diameter

- Compact footprint

- Yes

- Infeed method

- Infeed conveyor placed in line

- Machine design

- Hygienic

- Integration and synchronisation

- Portioning and flow wrapping

- Control panel type

- Integrated

- Compact footprint

- Yes

- Integration possibilities

- Portioning and flow wrapping integration

- Multiple counting units

- Available

- Machine Model Variants

- EURO 77 DT – big slab / single product

- Infeed conveyor configuration

- In line with flow wrapper