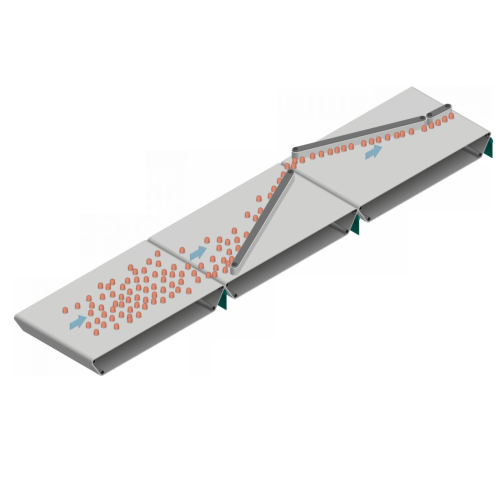

Separating and aligning conveyor for packaging systems

Efficiently manage the flow of diverse solid products like confectionery and tablets through seamless separation, alignment, and transfer, ensuring optimal line integration and enhanced operational productivity in high-speed packaging environments.

Separates, Aligns, and Transfers Solid Products

The Separating and Aligning Conveyor System from Theegarten-Pactec is designed to optimize the handling of solid products in food and confectionery production. It offers precise separation, alignment, and transfer of items such as sweets, chocolate products, and dishwasher tablets, ensuring seamless integration with packaging systems. Equipped with a three-phase motor and frequency controller, it supports continuous, high-speed operations and includes optional cooling for sensitive products. The conveyor features quick tensioning devices for low-maintenance and easy upkeep, with accessible design for cleaning. Ideal for handling a wide range of products, this system caters to industries including food, confectionery, and packaging, supporting efficient operations in both production and transport departments.

Benefits

- Enhances production efficiency with seamless integration into high-speed packaging operations.

- Minimizes maintenance costs through easy-access design and quick tensioning devices.

- Supports diverse product handling, from chocolates to dishwasher tablets, increasing production flexibility.

- Improves production cleanliness with removable supports for straightforward conveyor cleaning.

- Customizable staging and cooling options cater to specific product requirements and operational conditions.

- Applications

- Soft caramels, Bouillon cubes, Hard candies, Fudge, Chocolate products, Toffee, Cereals, Sweets, Jelly products, Effervescent tablets, Dishwasher tablets, Chewing gum

- End products

- Cornflakes, Bonbons, Fizzy drink tablets, Marshmallow candies, Butter toffees, Bubble gum, Vanilla fudge, Truffles, Bullion paste squares, Detergent pods, Chewable caramels

- Steps before

- Product preparation, Product shaping, Cooling

- Steps after

- Packaging, Distribution, Sealing

- Input ingredients

- chocolate products, soft caramels, hard candies, preformed products, jelly products, chewing gum, bubble gum products, effervescent tablets, eclairs, toffee, fudge, bouillon cubes, cereals, dishwasher tablets, krówki

- Output ingredients

- packaged chocolate products, wrapped soft caramels, packaged hard candies, packaged preformed products, wrapped jelly products, wrapped gum products, packaged effervescent tablets, wrapped eclairs, wrapped toffee, wrapped fudge, packaged bouillon cubes, packaged cereals, packaged dishwasher tablets, wrapped krówki

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Conveyor width

- MG5 = 350 mm, MG6 = 500 mm

- Stages

- Single- to five-stage execution

- Drive type

- Three-phase motor driven

- Automation

- Frequency controller integrated within the switch cabinet

- Cleaning accessibility

- Easy access through removable conveyor support plates

- Tension mechanism

- Quick tensioning devices for the conveyor belts

- Cooling option

- Optional

- Return shaft diameter

- 10 mm

- Maintenance access

- Swivelling frame for easy cleaning and maintenance access

- Automation level

- Manual / PLC

- Cleaning method

- Manual / Removable support plates

- Batch vs. continuous operation

- Inline Continuous

- Cooling option

- Optional Cooling

- Easy maintenance access

- Quick tensioning devices

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Conveyor width

- MG5 = 350 mm, MG6 = 500 mm

- Conveyor stages

- Single- to five-stage execution

- Cooling option

- Optional

- Return shafts diameter

- 10 mm

- Product guides

- Driven or static, attached to a swivelling frame

- Conveyor stage execution

- Single- to five-stage

- Cleaning method

- Easy access for cleaning

- Product guide type

- Driven or static

- Product guide frame

- Swivelling frame

- Scraper type

- With sliding waste trays

- Maintenance feature

- Quick tensioning devices