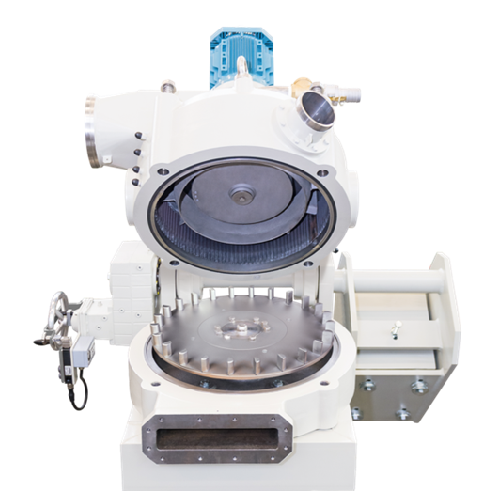

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced grinding and classification technology, perfect for ensuring consistent quality in chemical, cosmetic, and food processing applications.

Grinds and Classifies Diverse Materials

The Impact Classifier Mill ICM from NEUMAN & ESSER delivers precision grinding coupled with flexible classification for a range of industrial applications. This equipment excels in its ability to produce narrow particle size distributions, with classification settings as fine as 10 μm, making it ideal for products ranging from cosmetic powders to activated carbon. The mill’s integrated classifier provides highly selective separation, recycling coarse materials back into the grinding chamber for further reduction. Operating with a direct-drive system, it ensures energy efficiency and reduced maintenance. The ICM can process up to 20,000 kg per hour, with a robust design suitable for continuous and high-speed operations. Optional pressure shock resistance up to 11 bar allows safe handling of materials prone to explosion. The mill’s construction offers easy cleaning and maintenance, suited to industries like pharmaceuticals and food processing where contamination control is crucial. Designed for customization, it integrates seamlessly into existing production lines, supporting both chemical producers and mineral processors with specific configuration needs.

Benefits

- Ensures uniform product quality with precise particle size distribution control.

- Enhances operational safety with optional pressure shock resistance for explosive materials.

- Lowers energy expenses through a direct-drive system, reducing overall power usage.

- Facilitates seamless production integration with customizable configurations.

- Minimizes maintenance time with a design optimized for easy cleaning and upkeep.

- Applications

- Chemicals, Food, Fossil fuels, Metal powders, Coal, Cosmetics, Sweets, Minerals, Powder coating, Pigments, Pharmaceuticals

- End products

- Resin granules, Stearic acid powders, Activated carbon, Cocoa powder, Powder-coated surfaces, Wax pellets, Confectionery sugars, Vitamin supplements, Cosmetic blush powders, Powdered sugar for pharmaceuticals, Metal additive powders, Coal dust briquettes, Talc powder, Protein-enriched powders, Paint pigments

- Steps before

- Drying, Pre-grinding, Material handling, Material feeding

- Steps after

- Packing, Coating, Product separation, Quality control

- Input ingredients

- brittle materials, feed material, sugar, starch, milk powder, cocoa, tea leaves, fish bones, eggshells, sweeteners, vitamins, wax, resins, stearic acids, E-PVC, coal, lignite, coke, petroleum coke, torrefied wood, charcoal, carbonates, gypsum, graphite, talc, sodium bicarbonate, activated carbon, powder coating, inorganic pigments, organic pigments, metal powder

- Output ingredients

- fine and finest particles, narrow particle size distribution, precise product properties, controlled particle size: 10 μm to 2, 000 μm

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Particle Size Limitation

- 20 μm – 1, 000 μm

- Throughput

- 10 kg/h – 20, 000 kg/h

- Mill Power

- 2 kW – 350 kW

- Air Quantity

- 140 m³/h – 60, 000 m³/h

- Feed Material Particle Size

- 0 – 10 mm

- Grinding Chamber Diameter

- 150 mm – 2, 500 mm

- Particle Size Distribution

- Narrow

- Working mechanism

- Impact grinding with integrated classifier

- Flexibility of grinding fineness

- Adjustable via classifier’s rotary speed

- Particle size distribution

- Narrow, precise

- Cleanability

- Easy operation and cleaning

- Pressure shock resistance

- Available in PSR 11 version (up to 11 bar)

- Explosive environment suitability

- ATEX-compliant systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Grinding chamber diameter

- 150 mm – 2, 500 mm

- Mill Power

- 2 kW – 350 kW

- Air quantity

- 140 m³/h – 60, 000 m³/h

- Feed material particle size

- 0 – 10 mm

- Control panel type

- HMI with direct drive

- Integration

- ATEX-compliant systems

- Pressure shock resistance

- PSR 11 version

- Grinding fineness adjustment

- Flexible via rotary speed