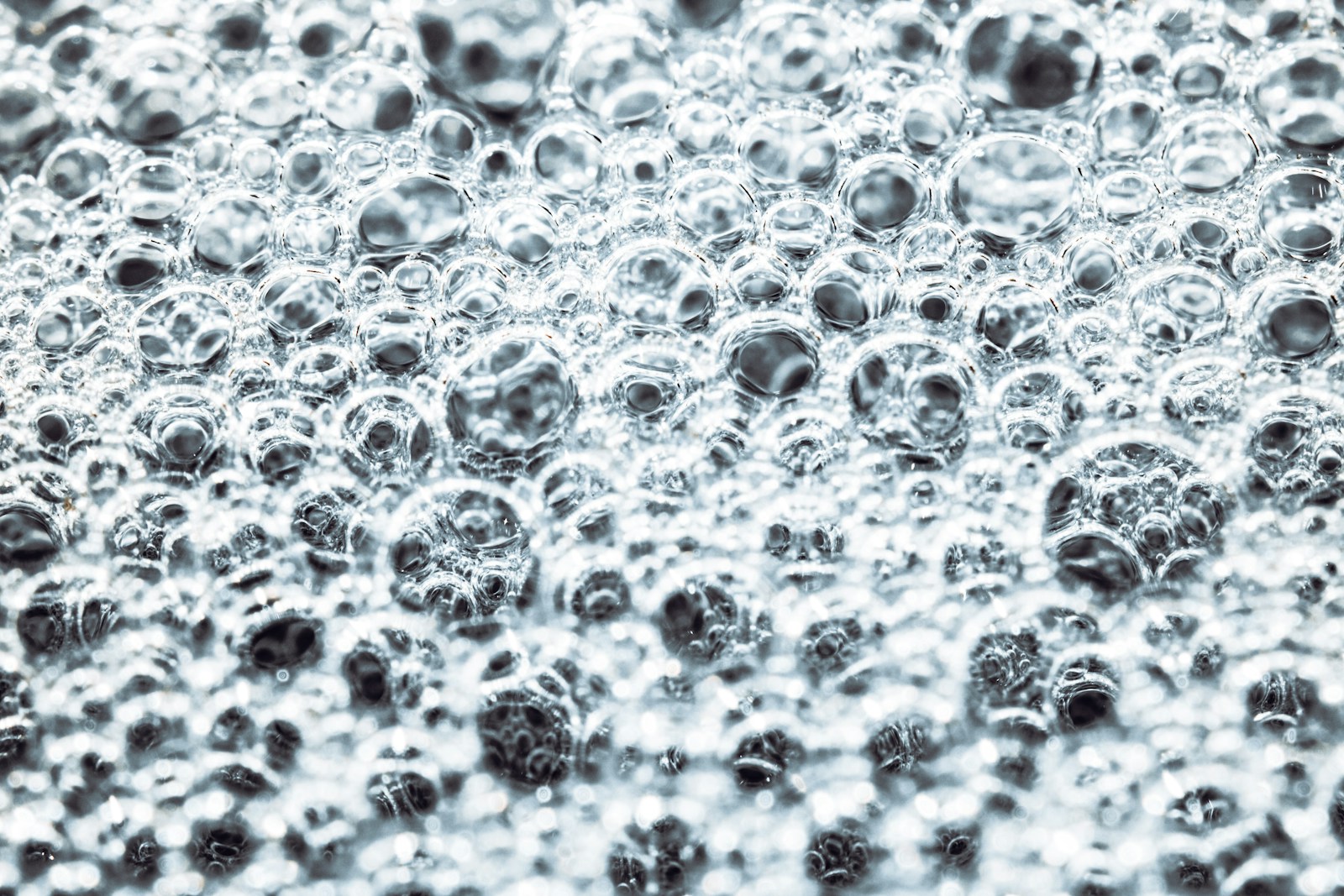

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for precise hydrocolloid processing, ensuring uniform texture and consistency in your jellies and candies.

Streamlines Confectionery Cooking and Forming

The PRINCESS® JELLYMASTER from CHOCOTECH is a sophisticated lab cooker system designed for precision in confectionery production. Utilizing state-of-the-art PLC control, it facilitates a range of processes including weighing, dissolving, and cooking, ideal for creating jellies, chocolates, and more. This system features a high shear mixer tailored for hydrocolloids and a Direct Steam Injection (DSI) jet cooker for efficient high amylose starch dissolution, ensuring rapid and uniform cooking. The JELLYMASTER caters to diverse applications, producing end-products like gummy bears, nougat chews, and peanut brittle with exacting standards. Its modular design allows seamless integration into lab settings, offering scalability from pilot to batch operations. This energy-efficient system is engineered for minimal maintenance with an emphasis on hygiene, featuring built-in vacuum systems and corrosion-resistant materials. Suitable for confectionery manufacturers, R&D departments, and food processing companies looking to innovate while maintaining consistent product quality.

Benefits

- Enhances product quality with precise control over cooking and forming processes.

- Reduces energy consumption through efficient steam injection technology.

- Facilitates rapid prototyping in R&D with scalable batch operations.

- Streamlines production with seamless integration into existing lab setups.

- Minimizes maintenance needs with robust and hygienic construction.

- Applications

- Jellies, Brittle, Halva, Fondant, Chewy candy, Hard candy, Candies, Foam, Chocolate, Caramel

- End products

- Chocolate truffles, Gummy bears, Sesame halva, Marshmallow candies, Nougat chews, Sugar fondant, Fruit jellies, Caramel chews, Aerated mousse, Lollipops, Peanut brittle

- Steps before

- Weighing, Dissolving, Cooking, Vacuuming

- Steps after

- Caramelization, Crystallization, Aeration, Cooling, Forming, Tempering

- Input ingredients

- hydrocolloids, starch, slurry

- Output ingredients

- jellies

- Market info

- CHOCOTECH is known for providing innovative solutions in the confectionery industry, specializing in machinery for processing and manufacturing chocolate, candies, and other sweets, with a reputation for precision engineering and tailored, high-quality equipment solutions.

- Automation

- PLC-controlled

- Capacity

- N/A (Lab scale)

- Mixer Type

- High shear mixer

- Mixer Function

- Hydrocolloids

- Pump Type

- Slurry metering pump

- Cooking Method

- Direct Steam Injection (DSI) jet cooker

- Dissolving Method

- Pressure dissolver

- Vacuum System

- Complete vacuum chamber

- Product Type

- All types of jellies

- Starch Type

- High amylose starch

- Design Type

- Skid-mounted

- Working mechanism

- High shear mixing

- Integrated steps

- Mixing, metering, dissolving, vacuuming

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Assumed CIP capability

- Cleaning method

- CIP / Manual

- Cleanability

- Easy cleaning with CIP

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Designed for hydrocolloids, high amylose starch

- Container size

- Customizable

- Product type

- Jellies, Gummies

- Tank shape and size

- Mix tank with high shear mixer

- Feed/discharge method

- Slurry metering pump

- Control panel type

- PLC-controlled

- Integration possibilities

- Direct Steam Injection (DSI) integration

- Footprint

- Lab-sized, skid-mounted

- System Configuration

- Mix tank with high shear mixer, slurry metering pump

- Vacuum System

- Complete vacuum chamber

- Material Handling

- High shear mixer for hydrocolloids