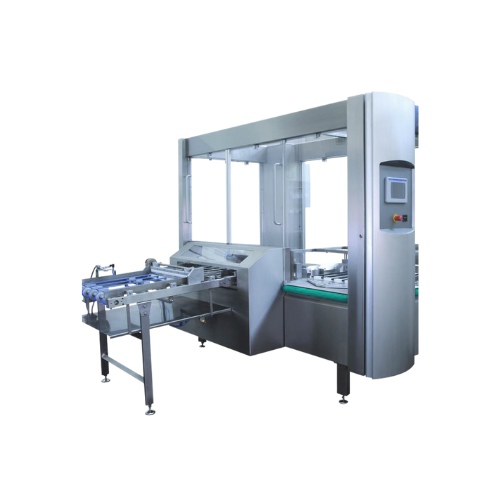

Wafer block cutter

Optimize your confectionery production with precision cutting technology that transforms wafer blocks into consistent, high-quality wafer fingers and snack bars. Achieve seamless integration into your processing line, maximizing efficiency and product quality with reduced manual handling.

Cuts and Separates Wafer Blocks into Fingers

The Franz Haas AWDM Wafer Block Cutter from Bühler Group is an advanced solution for efficiently processing wafer blocks. It utilizes a fully automatic operation to achieve up to 14 cuts per minute, transforming large blocks into precise wafer fingers and other products. This cutter integrates seamlessly into confectionery and baking production lines, reducing waste and ensuring high product quality. Its stainless steel construction guarantees compliance with stringent hygienic standards, making it ideal for food environments. Equipped with interchangeable cutting frames, it allows for customization of product sizes using wires or blades. The machine’s robust design includes a polycarbonate cover for production monitoring, while a rope conveyor and 90° cutting frame arrangement ensure accurate and efficient cutting operations. Ideal for snack, chocolate, and baked goods sectors, it supports varied applications, including chocolate wafer bars and biscuit sticks. This cutter is designed for high-capacity production, ensuring consistent output while simplifying maintenance with easy access for cleaning.

Benefits

- Increases production efficiency with automatic cutting and precise separation.

- Enhances hygienic standards with stainless steel construction, ensuring food safety.

- Allows for flexible product sizing, minimizing changeover time with interchangeable cutting frames.

- Simplifies maintenance with easy accessibility for cleaning and inspection.

- Optimizes product quality and reduces waste, ensuring consistent output.

- Applications

- Wafers, Confectionery, Baked goods, Snacks

- End products

- Cream-filled wafer blocks, Snack bars, Chocolate wafer bars, Biscuit sticks, Wafer fingers

- Steps before

- Cooling, Wafer baking, Conching, Conditioning

- Steps after

- Packing, Filling, Decorating, Sifting, grading

- Input ingredients

- wafer blocks

- Output ingredients

- wafer fingers

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Material

- Stainless steel

- Cutting Speed

- Up to 14 cuts per minute

- Cutting Method

- Wires or blades

- Operation

- Fully automatic

- Accessibility

- Easily accessible for cleaning

- Cover Type

- Polycarbonate

- Cutting Frame Angles

- 90°

- Format Variability

- Changeable cutting frames

- Automation level

- Fully automatic

- Changeover time

- Adjustable cutting frames

- Cleaning method

- Accessible for manual cleaning

- CIP/SIP

- No CIP integration

- Batch vs. continuous operation

- Batch operation

- Energy efficiency

- High efficiency with low energy consumption

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Stainless steel

- Yes

- Material of Construction

- Stainless Steel

- Frame Type

- Cutting frames with variable distance

- Cover Material

- Polycarbonate

- Conveyor Type

- Rope conveyor

- Operation

- Fully automatic

- Footprint

- Compact design

- Control panel type

- Fully automatic

- Integration possibilities

- Automatic operation

- Cutting frame options

- Variable sizes with wires or blades

- Material

- Stainless steel

- Cover type

- Polycarbonate