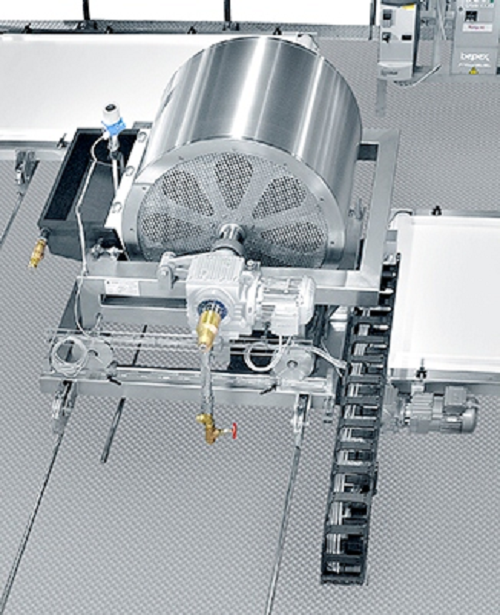

Cooling drum for soft and caramel mixtures

Cool your product to the temperature required for further processing. This is a continuous cooling unit for chewy and caramel masses designed to take output directly from a cooker and spread it evenly over the surface of the rotating drum for even and efficient cooling.

Consistent and even cooling with no sticking

The Cooling Drum line from Hosokawa Ter Braak is a continuous cooling drum with output levels of 300 to 600 kg/h of soft caramel. It is designed to evenly and consistently cool hot substrates in preparation for further processing. Efficient cooling is achieved without product sticking by continuously lubricating the inner wall of the drum’s cooling jacket upon which the product is evenly spread. Careful distribution of the chilling liquid inside the cooling jacket ensures maximum cooling with minimum input chilling energy. The line is part of Hosokawa Ter Braak’s line of continuous caramel processing equipment that has developed a strong international reputation for product quality and strong technical support to field applications.

Benefits

- Continuous output from 700 to 2,450 L/h

- Total machine length from 1.2 to 1.8 M

- Standard Drum Sizes of 1M and 1.5M

- Customized drum sizes and output levels available

- Closed-loop cooling water systems are available