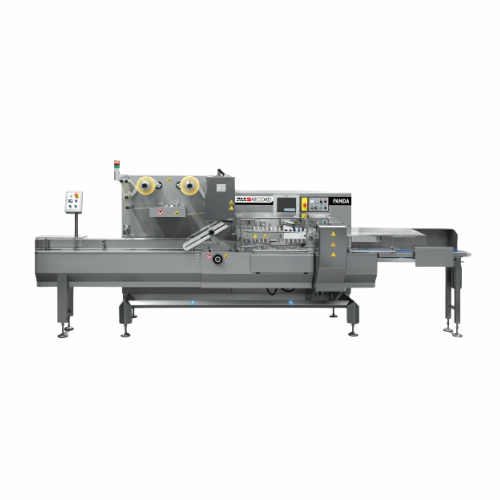

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrapping machine, designed for high-speed packing of diverse solid products, ensuring reliable protection with efficient sealing technology.

Packs and Seals Diverse Solid Products Efficiently

The PANDA BS RS from IMA Group is a versatile flowpack machine designed for high-speed operations across industries like food, dairy, and pharmaceuticals. This machine specializes in packing a variety of solid products, such as candy bars, chocolate truffles, and blister-packed pills, ensuring secure and attractive packaging. Its rotating sealing jaws enable speeds of up to 300 packs per minute, with options for single or double jaws to accommodate different packaging materials, including heat-shrinkable films. With customizable solutions and a wash-down version available, it seamlessly integrates into your production line. Constructed with food-grade materials, it is easy to sanitize, supporting hygiene and efficiency. The PANDA BS RS offers up to 750mm product width capacity, ensuring flexible application across various product types.

Benefits

- Increases production efficiency with speeds up to 300 packs per minute.

- Customizable design adapts to specific packaging needs, enhancing operational flexibility.

- Reduces contamination risk with easy-to-clean, food-grade construction.

- Optimizes space with integration capabilities for seamless production flow.

- Minimizes setup time through versatile product size accommodation.

- Applications

- Home care, Nonwoven, Snacks, Confectionery, Tissue, Beverage, Coffee, Packaged food, Sweets, Personal, Tea, Dairy products, Pharmaceuticals

- End products

- Chocolate truffles, Blister-packed pills, Packaged tea bags, Instant noodle packs, Cheese slices, Face masks, Bottled beverages, Facial tissues, Potato chips, Candy bars, Coffee pouches, Wet wipes, Detergent pods

- Steps before

- Dosing and wrapping, Pressing, Pouch filling, Form Fill and Seal, Horizontal form fill and seal

- Steps after

- Cartoning, Case packing and palletizing

- Input ingredients

- regular small products, medium size products, wrapping material, heat-shrinkable material, food-grade basic material

- Output ingredients

- flow-packed products, good-looking pack, customized packs, sanitized product

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Machine speed

- 150–300 packs per minute

- Product width (mm max.)

- 750

- Product depth (mm max.)

- 280–355

- Product height (mm max.)

- 120–180

- Film width (mm max.)

- 730–930

- Cut-off length (mm max.)

- 850

- Jaws width (mm max.)

- 170–350

- Film linear speed (m/min.)

- 50

- Automation

- Customizable

- Packing Speed

- 150 to 300 packs per minute

- Pack Size Range

- Small to medium

- Sealing Type

- Rotating sealing jaws

- Integration Capability

- Can be integrated into complete process flow

- Customization Level

- High level of customization available

- Material Type

- Food grade, easy to sanitize

- Wash-down Version

- Available

- Machine speed

- 150–300 packs per minute

- Product width

- Up to 750 mm

- Product depth

- Up to 280 mm

- Product height

- Up to 120 mm (180 mm for the larger version)

- Film width

- Up to 730 mm (930 mm for the larger version)

- Cut-off length

- Up to 850 mm

- Jaws width

- Up to 350 mm (450 mm for the larger version)

- Film linear speed

- Up to 50 m/min

- Flexibility

- Suitable for a wide range of products and pack sizes

- Wash-down version

- Available

- Integration possibilities

- Complete process flow integration

- Customization level

- High level of customization

- Wash-down version

- Available

- Product range adaptability

- Wide range of products and pack sizes

- Sealing jaw type

- Single or double rotating