Industrial sandwich pancake system

Streamline your production with a machine that seamlessly integrates baking, filling, printing, and sealing into one efficient process, opening up endless possibilities for innovative sandwich pancake creations.

Produces and Assembles Filled Sandwich Pancakes

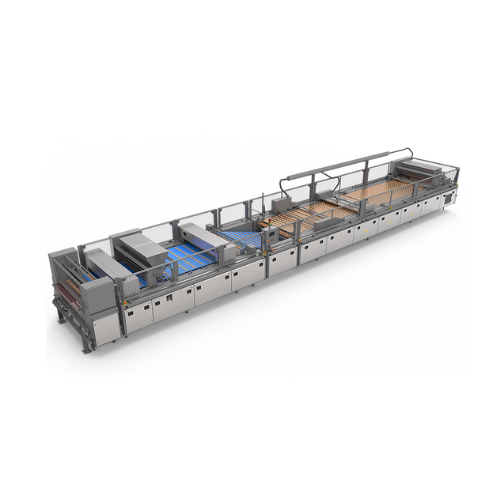

The Sandwich Pancake Making Machine from Cake Concepts is a fully automated solution designed to optimize the production of filled sandwich pancakes in industrial baking environments. This machine excels with its modular and flexible design, allowing seamless integration into existing production lines. It employs processes like baking, filling, printing, and sealing to ensure high-quality dorayaki and custom-printed pancake creations.

Ideal for food, bakery, and confectionery industries, it consistently produces a range of end products including double-filled pancakes and mini dorayaki snacks. With a processing capacity of up to 12,000 pieces per hour, it caters to continuous production needs with reliable operational efficiency. The machine uses both gas and electricity for heating, providing flexibility and energy efficiency in varied production settings.

The system’s modular units facilitate easy cleaning and maintenance while adhering to the highest food safety standards. Additionally, the equipment’s design supports customization to meet specific production requirements, ensuring that each component aligns with your unique operational conditions.

Benefits

- Enhances production efficiency with fully automated processes, reducing manual labor requirements.

- Supports high-capacity output of up to 12,000 pieces per hour for large-scale operations.

- Improves product consistency and quality with precise filling and sealing mechanisms.

- Offers flexible production capabilities with modular design, facilitating quick adjustments to product specifications.

- Ensures compliance with food safety standards, securing product integrity in industrial settings.

- Applications

- Baked goods, Snacks, Sandwich pancakes, Confectionery, Sweets, Desserts

- End products

- Triple-layer pancakes, Double-filled pancakes, Sweet pancake sandwiches, Mini dorayaki snacks, Filled sandwich pancakes, Dorayaki, Custom-printed pancakes

- Steps before

- Mixing Ingredients, Batter Preparation, Pancake Alignment

- Steps after

- Printing, Filling Application, Pancake Sealing, Packaging

- Input ingredients

- pancake batter, fillings, gas or electricity

- Output ingredients

- sandwich pancakes, dorayaki, printed pancakes, sealed pancakes

- Market info

- Automation

- Fully automatic system

- Heating Source

- Gas/Electricity

- Capacity

- 3000, 6000 and 12000 pcs/hr

- Output

- 100 to 650 kg/hr

- Baking Surface

- Reinforced copper plate

- Synchronous Operation

- Pancake griddle and sandwiching machine

- Pancake Alignment

- Vacuum lifting

- Heating Element Position

- Top-mounted

- Modular Design

- Functions built as modular units

- Filling Type

- Single, Sandwiched or Mini pancake

- Working mechanism

- All-in-one pancake machine with baking, filling, printing, and sealing

- Integrated steps

- Depositing, sealing, printing

- Automation level

- Fully automatic system

- Batch vs. continuous operation

- Continuous

- Changeover time

- Flexible modular units

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- Modular

- Discharge method

- Sealing unit

- Heating Source

- Gas / Electricity

- Modular Units

- Sealing / Printing / Depositing

- Production Capacity

- 3000, 6000, 12000 pcs/hr

- Print Design

- Interchangeable Print Heads

- Filling Options

- Single / Double / Triple Sandwich

- Output Range

- 100 to 650 kg/hr