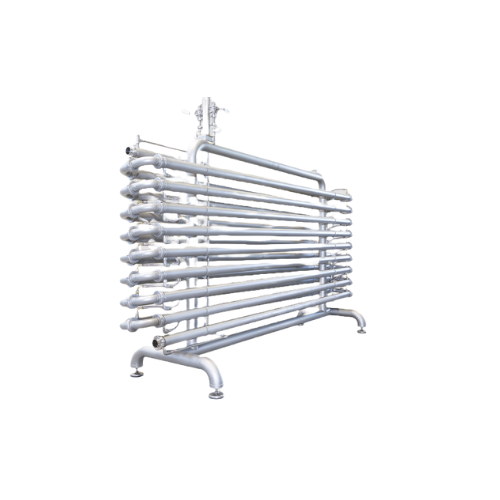

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed for precision temperature control, ideal for maintaining texture and flavor in your jelly, foam, and caramel products.

Cools Confectionery Products Precisely

The SUCROSTAR® from CHOCOTECH GmbH is a specialized static cooler, essential for confectionery manufacturers focusing on jelly, foam, and caramel products. With its hygienic design suited for CIP (Clean-In-Place) applications, the SUCROSTAR® facilitates a gentle cooling process, maintaining product integrity without spoilage. Its static operation is ideal for products such as caramel chews and marshmallows, ensuring precise temperature management essential for delicate confectionery textures. The SUCROSTAR® integrates smoothly into your production line, offering user-friendly controls for seamless operation. Designed for efficiency, it supports the preservation of both solid and foam products, enhancing your production capabilities while maintaining quality and consistency.

Benefits

- Ensures product quality by preventing spoilage during cooling.

- Facilitates seamless integration with existing production lines.

- Reduces cleaning time with hygienic CIP capability.

- Maintains delicate textures for a variety of confectionery products.

- Increases operational efficiency with user-friendly controls.

- Applications

- Jelly, Caramels, Confectionery, Sweets, Foam

- End products

- Marshmallows, Protein caramels, Jelly beans, Caramel chews, Nougat

- Steps before

- Weighing, Dissolving, Cooking, Vacuuming, Caramelization, Crystallization, Aeration

- Steps after

- Forming, Tempering, Packing

- Input ingredients

- jelly, foam, protein type masses, caramels

- Output ingredients

- cooled jelly, cooled foam, cooled caramel

- Market info

- CHOCOTECH is known for providing innovative solutions in the confectionery industry, specializing in machinery for processing and manufacturing chocolate, candies, and other sweets, with a reputation for precision engineering and tailored, high-quality equipment solutions.

- Cooler Type

- Static

- Cooling Application

- Jelly and Foam Manufacturing

- Design Feature

- Hygienic and Suitable for CIP

- Operation Type

- Dynamic and Static

- Cooling Process

- Gentle and Effective

- Support Mass Type

- Protein Type Masses

- Cooling method

- Static

- Application type

- Jelly/Foam Manufacturing

- CIP/SIP Capabilities

- CIP Compatible

- Cooling process

- Gentle and Effective

- Automation level

- User-friendly

- Cleanability

- Hygienic design, suited for CIP applications

- Shape

- Static

- Cooling type

- Static type cooler

- Design

- Hygienic design

- Application type

- Jelly and foam manufacturing

- CIP suitability

- Yes

- Control panel type

- User-friendly HMI

- Integration possibilities

- CIP applications compatible

- Design type

- Static cooling

- Cooling method

- Gentle but effective

- Application type

- Jelly and foam manufacturing

- Construction Material

- Hygienic design