Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup filling system, perfect for delivering precise dual-colored chocolate and soft candy cups for maximum product appeal.

Fills and Deposits Dual-Color Chocolate Cups

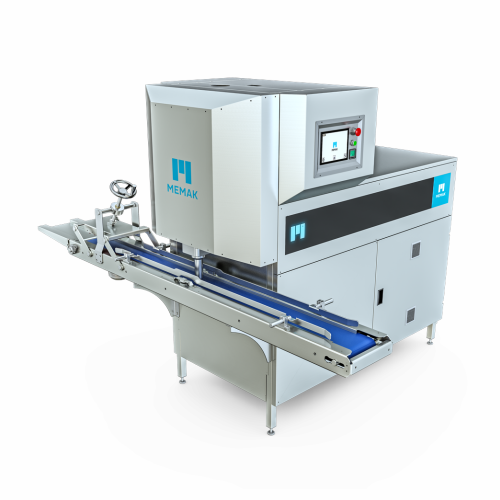

The MKCF-200 Cup Filling Machine from Memak Professional Chocolate and Bakery Machines is purpose-built for filling dual-color masses in confectionery production. This machine distinguishes itself with its 12-nozzle depositor system, allowing for precise filling and versatile production capabilities of chocolate spreads, layered treats, and confectionery toppings. Operating at a capacity of 6-8 containers per minute, with a range of 100-1000 grams, it integrates seamlessly into existing production lines with its automatic operation and adjustable conveyor. The machine’s high-speed capabilities make it ideal for chocolate manufacturers and bakery businesses looking to enhance their efficiency. Made with durable materials, the MKCF-200 offers easy integration with filling and depositing systems, ensuring reliable performance in food, bakery, and candy production sectors. Its versatility extends to both liquid and slurry types while maintaining energy efficiency with a total power consumption of 6.5 kW.

Benefits

- Enhances production flexibility with dual-color filling capabilities.

- Increases efficiency with a throughput of 6-8 containers per minute.

- Minimizes setup disruptions through easy conveyor adjustment.

- Supports diverse product range, handling both liquid and slurry formats.

- Reduces operational energy consumption with optimized power use.

- Applications

- Snacks, Bakery, Sweets, Chocolate, Soft candy

- End products

- Dual-colored chocolate cups, Vanilla and chocolate soft candy cups, Decorative confectionery toppings, Chocolate-filled jars, Chocolate spreads, Layered chocolate treats

- Steps before

- Chocolate Pre-Mixing, Sugar Powder Milling, Fat Melting

- Steps after

- Wrapping, Cooling, Chocolate Moulding, Nougat and Cereal Bar Forming

- Input ingredients

- mass, double colors mass

- Output ingredients

- filled jars, filled buckets

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Machine Type

- Cup Filling Machine

- Product Code

- MKCF-200

- Capacity

- 6-8 pcs/min (100-1000gr)

- Total Power

- 6.5 kW

- Number of Nozzles

- 12 Nozzles (6+6)

- Filling Range

- 100-1000gr

- Working mechanism

- Depositor system with nozzles

- Integrated steps

- Dual-color filling

- Conveyor system

- Adjustable

- Filling method

- Automatic

- Nozzles

- 12 Nozzles (6+6)

- Double color filling capability

- Yes

- Batch vs. continuous operation

- Batch

- Automation level

- Automatic control

- Cleanability

- Yes

- Biological compatibility

- Food-grade

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Varied

- Nozzle Configuration

- 12 Nozzles (6+6)

- Filling Range

- 100-1000 g

- Conveyor Type

- Adjustable Conveyor

- Footprint

- N/A

- Control Panel Type

- HMI / PLC

- Nozzle Configuration

- 12 Nozzles (6+6)

- Filling Range

- 100-1000g

- Conveyor Adjustment

- Adjustable

- Color Filling Options

- Double Colors