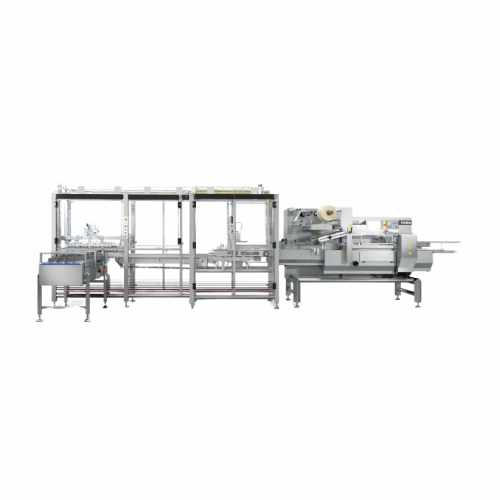

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping for biscuits and crackers, ensuring secure sealing and precise edge-packing.

Wraps and Seals Biscuits and Snacks

The PANDA BS OE from IMA Group is a versatile flow wrapping machine designed for efficiently packaging products like biscuits, crackers, and other snacks. What sets this equipment apart is its adaptability to both semi and fully automated environments, addressing diverse packaging needs with customizable sealing jaws—either rotating or long-dwell—based on product requirements. It operates within a maximum speed of 130 packs per minute, ensuring high throughput with precision. Constructed with food-grade materials, it features an easy-to-sanitize design, with options for a wash-down version for enhanced hygiene. Suitable for integration into a complete process flow, the machine can be configured with automatic feeding systems and is ideal for food, dairy, and confectionery industries. With a capacity to handle products up to 300mm wide and 180mm high, it supports a variety of pack sizes, enhancing operational efficiency in any production line.

Benefits

- Enhances production efficiency with customizable automation options.

- Supports diverse packaging needs with flexible pack size capabilities.

- Ensures hygiene with easy-to-clean, food-grade design.

- Integrates seamlessly into existing production lines, optimizing workflow.

- Reduces maintenance time with durable construction and optional wash-down version.

- Applications

- Sweets, Biscuits, Crackers, Snacks

- End products

- Digestive biscuits, Potato crisps, Saltine crackers, Gummy candies, Cream-filled wafers, Cheese crackers, Fruit-flavored snacks, Chocolate-covered nuggets

- Steps before

- Dosing, Pressing, Pouch filling

- Steps after

- Cartoning, Case packing, Palletizing

- Input ingredients

- biscuits, crackers

- Output ingredients

- wrapped biscuits, wrapped crackers, packaged products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Machine speed

- 130 ppm (PANDA BS RS OE), 60 ppm (PANDA BS LS OE)

- Product width

- 300 mm max

- Product depth

- 130 mm (180 mm) max (PANDA BS RS OE), 150 mm max (PANDA BS LS OE)

- Product height

- 80 mm (110 mm) max (PANDA BS RS OE), 160 mm (180 mm) max (PANDA BS LS OE)

- Film width

- 730 mm (930 mm) max

- Cut-off length

- 400 mm max

- Jaws width

- 170 mm (250 mm) max

- Film linear speed

- 50 m/min

- Automation Level

- Semi and Fully Automated

- Sealing Type

- Rotating Jaws (PANDA BS RS OE) / Long-Dwell (PANDA BS LS OE)

- Machine speed

- 60-130 ppm

- Automation level

- Semi / Fully automated

- Integration capability

- Complete process flow

- Cleaning method

- Easy to sanitize design

- Customizability

- High level of customization

- Pack types

- On edge for products like biscuits

- Sealing jaw types

- Rotating jaws / Long-Dwell

- Cleanability

- Easy to sanitize design

- Product positioning

- On edge

- Product customization

- High level

- Suitable product types

- Biscuits, crackers

- Suitable applications

- Semi and fully automated

- Machine footprint

- Compact

- Product width

- 300 mm max.

- Product depth

- 130 (180) mm max.

- Product height

- 80 (110) mm/160 (180) mm max.

- Film width

- 730 (930) mm max.

- Cut-off length

- 400 mm max.

- Jaws width

- 170 (250) mm max.

- Film linear speed

- 50 m/min.

- Wash-down version

- Available

- Sealing Jaws Head Units

- Rotating jaws (PANDA BS RS OE) / Long-Dwell (PANDA BS LS OE)

- Integration Possibilities

- Automatic feeding systems

- Machine Version

- Semi and fully automated applications

- Product Compatibility

- Wide range of products and pack sizes

- Wash-down Version

- Available