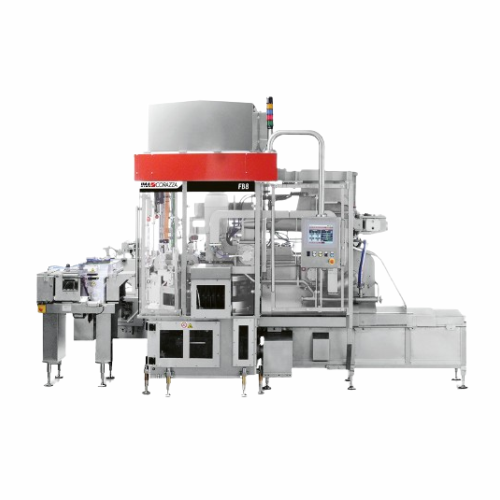

Butter portion dosing and wrapping system

Efficiently manage butter portion packaging with a compact system designed for precise dosing and versatility in packaging styles, ensuring reduced energy consumption and quick changeovers for varying production demands.

Doses and Wraps Butter Portions Efficiently

The FB Series from IMA Corazza is a state-of-the-art dosing and wrapping machine specifically engineered for butter and dairy products. What sets this equipment apart is its independent, servo-driven dosing system, ensuring high precision in portion control. Featuring a compact footprint, it’s designed for varied production speeds, handling up to 800 portions per minute with the FB8 model and 280 portions per minute with the FB220. The FB Series caters to different operational needs, offering both high-speed and fully mechanical options to suit varying production demands of dairy producers and butter manufacturers.

This versatile machine supports recyclable packaging materials and incorporates an energy-efficient motorization system, where kinetic energy from braking is shared among modules. For seamless integration, the FB Series boasts a user-friendly HMI and allows swift changeovers for different portion sizes. Key applications include dosing and wrapping processes to produce square and rectangular butter packs, as well as dairy spread portions. Each variant is constructed to fit seamlessly into a processing line, facilitating downstream cartoning and palletizing operations. With optional features like a weight-checker providing electronic feedback to dosing pistons, the FB Series ensures optimal productivity, precise dosing accuracy, and reduced energy consumption.

Benefits

- Enhances productivity with high-speed operations, reducing cycle times.

- Promotes sustainability using recyclable packaging materials and energy-efficient motorization.

- Offers precise portion control with independent, servo-driven dosing system for consistent quality.

- Minimizes downtime with quick and easy changeovers, streamlining production shifts.

- Reduces operational costs through shared kinetic energy and lower power consumption.

- Applications

- Food packaging, Butter, Dairy products

- End products

- Square butter packs, Recyclable butter wrappers, Butter portions, Dairy spread portions, Rectangular butter packs

- Steps before

- Chilling, Emulsification, Mixing

- Steps after

- Packing, Cartoning, Palletizing

- Input ingredients

- butter, foil, shell

- Output ingredients

- wrapped butter portions, butter mini portions, rectangular portions, square portions

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Capacity

- FB8

- Compressed Air Consumption

- FB8

- Weight

- FB8

- Shape

- Rectangular, Square

- Box Dimensions - A (min ÷ max)

- 20 ÷ 30 / 30 max.

- Box Dimensions - B (min ÷ max)

- 20 ÷ 40 / 20 ÷ 50

- Box Dimensions - C (min ÷ max)

- 6 ÷ 25 / 7 ÷ 18

- Weight Range (min ÷ max)

- FB8

- Dosage Accuracy

- High efficiency and precise dosing accuracy

- Full Load Current

- 3P x 400 Volt – 50 Hz – 18 Amp, 3P x 400 Volt – 50 Hz – 5 Amp

- Automation

- Independent, servo-driven dosing system

- Working mechanism

- Servo-driven dosing system

- Portion size changeover

- Quick and easy changeover

- Flow type

- Continuous

- Speed operation

- High-speed (800 ppm) / Low-speed (280 ppm)

- Energy recovery

- Kinetic energy utilization

- Footprint

- Compact

- Packaging material compatibility

- Sustainable and recyclable

- User interface

- User-friendly HMI

- Machine footprint

- Compact

- Shape

- Rectangular/Square

- Weight

- 5, 700 Kg / 2, 250 Kg

- Control panel type

- User-friendly HMI

- Box dimensions

- A

- Compressed Air Usage

- 250 Nl/min. (FB8), 100 Nl/min. (FB220)

- Discharge method

- Wrapped portions outfeed

- Compact footprint

- Yes

- Changeover capability

- Easy, quick changeover of portion base size

- Control panel type

- User-friendly HMI