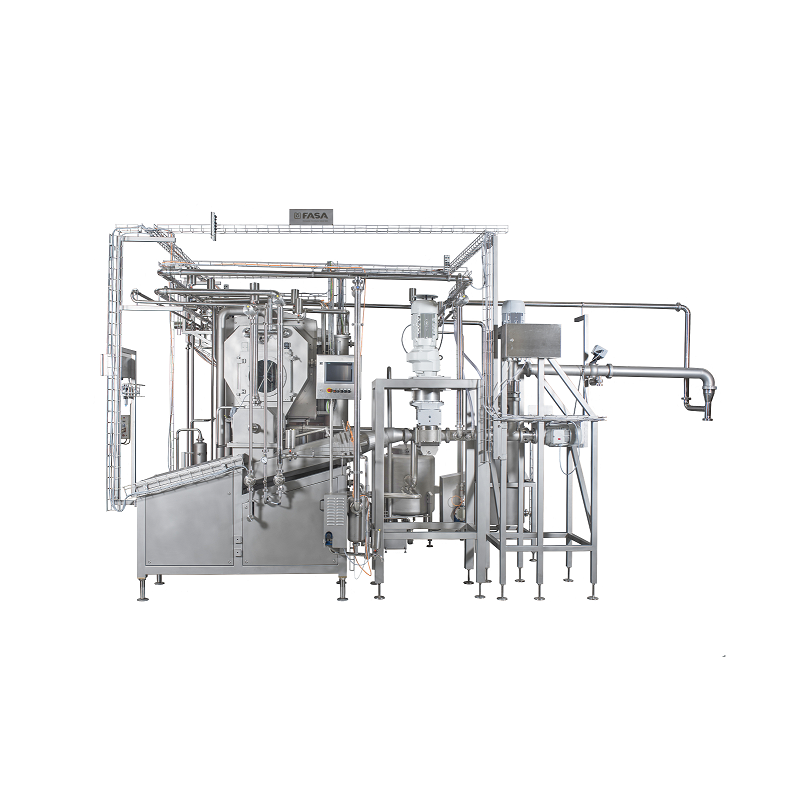

Continuous butter production line

When producing large volumes of butter in consistent quality, taste and appearance you need to control key factors such as separating temperature, butter moisture and proper drainage of butter milk.

Optimal beating, gentle churning and proper separation of butter grains and butter milk

The Continuous Butter making Machine (BMM) from FASA facilitates butter production from ripened cream. Different versions of this machine have the capacity to handle cream processing at a rate of up to 10000 l/hr and 5000l/batch. The machine delivers butter milk with a low-fat content up to 0.5%, while using cream with fat content of 35 to 42%. For the product with fat content 72,5% -82,5% no stabilizers and emulsifiers are needed. The vacuum chamber achieves low air content in butter for improved shelf life and a special moisture metering system is integrated. Different kinds of dosing units are available for ingredients such as moisture, culture, oil (for spreads production), dry ingredients (mushroom, herbs, cacao etc) and salt.

The process flow of the continuous butter making machine comprises of a cream beater, churning section, separating drum, kneading sections, vacuum chamber, butter milk collection tank with level control, butter milk pump and cooling system. The freshly produced butter can be directly fed to a packaging machine via a butter silo.

Benefits

- Scalable solution

- Improved shelf life

- CIP cleanable design

- Easy maintenance

- Stable quality characteristics