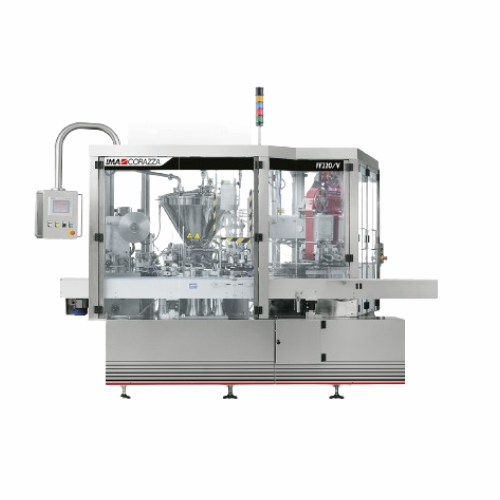

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrapping that promises smooth operations while minimizing maintenance needs.

Doses and Wraps Cheese Portions Efficiently

The FF220 Series from IMA Group is a sophisticated dosing and wrapping solution tailored for the dairy industry. This series offers smooth, continuous operation with minimal maintenance, capable of handling fresh, cream, and processed cheese portions in various shapes such as triangular, square, and rectangular. With a production capacity of up to 240 portions per minute, the FF220 Series integrates seamlessly into high-speed production lines, offering flexible configurations to meet diverse production needs. Its advanced motorization reduces power waste by utilizing kinetic energy during braking, and optional vacuum pumps further enhance energy efficiency by decreasing compressed air consumption. Constructed with stainless steel coatings for ease of cleaning, the machine supports sustainable packaging materials and optimized foil cutting for material savings. The FF220 also features a removable dosing assembly and a quick-change foil cutting unit to minimize downtime, ensuring uninterrupted high-volume production.

Benefits

- Enhances production efficiency with up to 240 portions per minute.

- Minimizes maintenance requirements due to smooth operational design.

- Reduces energy usage through effective kinetic energy recovery and vacuum integration.

- Supports sustainable manufacturing with recyclable packaging material.

- Facilitates quick cleaning and part changes to maintain uninterrupted operations.

- Applications

- Cream cheese, Processed cheese, Fresh cheese

- End products

- Triangular fresh cheese portions, Rectangular processed cheese portions, Square processed cheese portions, Square cream cheese portions, Round fresh cheese portions, Triangular cream cheese portions

- Steps before

- Cheese Preparation, Cheese Mixing, Cheese Emulsification

- Steps after

- Packing, Labeling, Final Inspection

- Input ingredients

- fresh cheese, cream cheese, processed cheese, alufoil, labels, sustainable packaging materials

- Output ingredients

- triangular cheese portion, square cheese portion, rectangular cheese portion, round cheese portion

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Capacity

- 200–240 portions/min

- Full Load Current

- 3P x 400 Volt – 50 Hz – 11 Amp

- Compressed Air Consumption

- 80 Nl/min. (min. op. pressure 6 bar)

- Vacuum

- 60 m³/h (op. vacuum 600 ± 50 mm Hg)

- Weight

- 4, 500 Kg Approx.

- Shape Options

- Triangular, Square, Rectangular

- Box Dimensions

- A (min ÷ max) 25 ÷ 60, B (min ÷ max) 25 ÷ 55, C (min ÷ max) 8 ÷ 26

- Weight Range for Portions

- 10g ÷ 40g

- Reel Width

- As per FF220/DX machine

- Sustainability Features

- Kinetic energy sharing

- Automation level

- High-performance, PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick reel and foil change

- Energy efficiency

- Kinetic energy sharing

- CIP/SIP

- Not specified, easy cleaning

- Cleaning method

- Manual, stainless steel facilitates cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Weight

- 4, 500 Kg Approx.

- Portion shape

- Rectangular, Square, Triangular, Round

- Machine configuration

- Customizable to customer requirements

- Shape options

- Rectangular, square, triangular

- Control panel type

- PLC-controlled

- Film and lid unwinding

- Excluded during machine operation

- Label magazine type

- Fixed for ease of filling