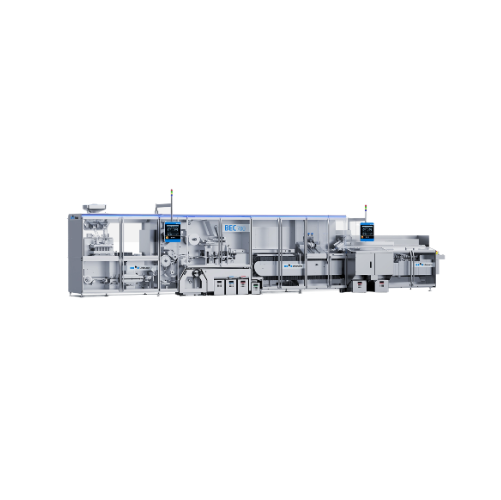

Semi-automatic butter bulk filling system

Optimize your dairy production with a seamless butter packaging solution that ensures consistent fill volumes and integrates smoothly with existing processing systems for efficient product flow and cleaning.

Fills and Packages Bulk Butter Efficiently

The PMG-10 from TREPKO is a semi-automatic bulk butter filling machine that enhances your dairy or food processing operations by ensuring consistent and accurate filling of butter and margarine blocks. Constructed from food-grade stainless steel, it integrates a product compensator directly connected to the filler, which maintains a steady product supply and adjusts the TREPKO filler’s speed accordingly, providing operational stability and efficiency. This machine is essential for producing butter blocks, dairy spreads, and bulk butter packs, streamlining packaging while minimizing manual intervention. Operating in semi-automatic mode, it supports integration into existing processing lines and features a capability for controlled cleaning via an integrated CIP process. Though customization options are available, the PMG-10 excels in maintaining product integrity and process efficiency.

Benefits

- Ensures precise filling, minimizing manual handling and boosting packaging efficiency.

- Integrates smoothly with existing systems, optimizing production workflow.

- Enhances operational stability with real-time product flow adjustment.

- Facilitates quick, efficient cleaning with built-in CIP compatibility.

- Maintains hygienic standards with durable, food-grade stainless steel construction.

- Applications

- Butter, Dairy products

- End products

- Butter blocks, Margarine blocks, Dairy spreads, Butter bricks, Bulk butter packs

- Steps before

- Mixing, Emulsification, Homogenization, Quality Control

- Steps after

- Carton Adjustment, Manual Filling, Sealing, Pneumatic Carton Movement

- Input ingredients

- butter type products, cartons

- Output ingredients

- filled cartons, bulk packaged butter

- Market info

- Filling method

- Semi-automatic

- Material

- Food grade stainless steel

- Fill type

- Bulk filling

- Flow control

- Automatic adjustment

- Carton handling

- Pneumatic

- Feedback system

- Automatic

- Scroll type

- Double scroll chute

- Carton movement

- Pneumatic 90° rotation

- Connection

- Direct connection to filler

- CIP process

- Flow controlled cleaning

- Compensator type

- Product compensator

- Filling Mechanism

- Semi-automatic

- CIP Process

- Instrument-integrated for cleaning solutions

- Flow Control

- Automatic adjustment via feedback

- Carton Orientation

- Horizontal, rotation to vertical

- Product Supply Monitoring

- Compensator ensures constant flow

- Automation Level

- Semi-automatic with manual adjustments

- Food grade material

- Stainless steel

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- High resistance

- Material

- Food grade stainless steel

- Discharge method

- Pneumatic movement

- Machine type

- Semi-automatic

- Carton orientation

- Horizontal

- Rotates pneumatic through 90°

- Control panel type

- Standard / Customizable HMI

- Integration possibilities

- 3rd party equipment integration

- Filling head configuration

- Single / Double scroll chute

- Operational adjustments

- Automatic speed control