Pneumatic knife for forming and cutting pasty products

Achieve precision and speed in forming and cutting various pasty products like dough and cheese with a high-speed pneumatic knife, ensuring consistent product quality and efficient production output.

Forms and Cuts Pasty Products Precisely

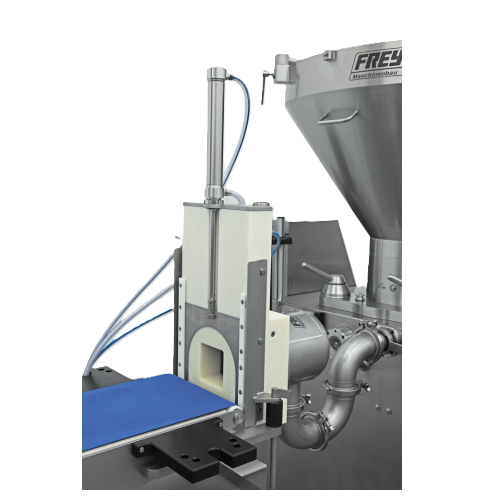

The PM 200 Pneumatic Knife from Frey Maschinenbau is engineered for high-speed forming and cutting of cylinder-shaped pasty products. Unique for its precision cutting capabilities, it operates under continuous pneumatic pressure, handling solid and cake-type items like pizza dough, butter blocks, and cheese wheels. This versatile machine accommodates diameters up to 200 mm, with optional wire cutter expansion for increased throughput up to 150 portions per minute. Ideal for food, bakery, confectionery, and dairy industries, it integrates seamlessly into production lines with its straightforward compressed air connection and includes a control unit for efficient stuffer management. Fabricated with robust materials, it maintains optimal performance with minimal energy consumption, meeting DIN ISO 8573-1 class 2 standards to ensure reliable and clean operations.

Benefits

- Enhances production efficiency with rapid, precise portioning at up to 150 cuts per minute.

- Simplifies integration into existing lines with easy-to-use pneumatic controls.

- Lowers operation costs through optimized air consumption, maintaining pressure at 6 bar.

- Offers versatility by handling a wide range of product diameters and types.

- Ensures consistent product quality with reliable and precise cutting technology.

- Applications

- Cookies, Pizza dough, Shortcrust pastry, Cheese, Bars, Butter

- End products

- Cheese wheels, Butter blocks, Pizza crusts, Tart shells, Shortbread cookies, Protein bars

- Steps before

- Dough preparation, Mixing, Ingredient blending

- Steps after

- Packaging, Cooling, Baking (for pizza dough)

- Input ingredients

- pizza dough, butter, cookies, bars, shortcrust pastry, cheese

- Output ingredients

- cylinder-shaped pasty products, formed products, cut products

- Market info

- Frey Maschinenbau is known for manufacturing high-quality, engineered-to-order industrial equipment, specializing in innovative solutions and precision engineering. They have a strong reputation for reliability and customer-focused service in the industrial machinery market.

- Diameter capacity

- Up to 200 mm

- Portion speed

- Max 90 portions/min

- Wire cutter speed

- 150 portions/min

- Air consumption

- 6 bar / 46 l/min

- Compressed air requirement

- DIN ISO 8573-1 class 2

- Control unit

- Incl. control unit for stuffer control

- Tube connection

- Incl. individual tube connection

- Working mechanism

- Pneumatic knife

- Cutting speed

- Up to 90 portions/min, wire cutter

- Product diameter range

- Up to 200 mm

- Air consumption

- 6 bar / 46l/min

- Automation level

- Includes control unit for stuffer control

- Compressed air requirement

- DIN ISO 8573-1 class 2

- Optional feature

- Wire cutter available

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade

- Cleanability

- CIP-compatible

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- Formable Product Types

- Pizza dough, butter, cookies, bars, shortcrust pastry, cheese

- DIN ISO 8573-1

- Class 2

- Machine footprint

- Compact design for ease of integration

- Feed/Discharge method

- Pneumatic knife for cutting

- Cylinder diameter

- Up to 200 mm

- Portion control

- Max. 90 portions/min

- Optional accessory

- Wire cutter available

- Control panel type

- Incl. control unit for stuffer control

- Discharge method

- Wire cutter