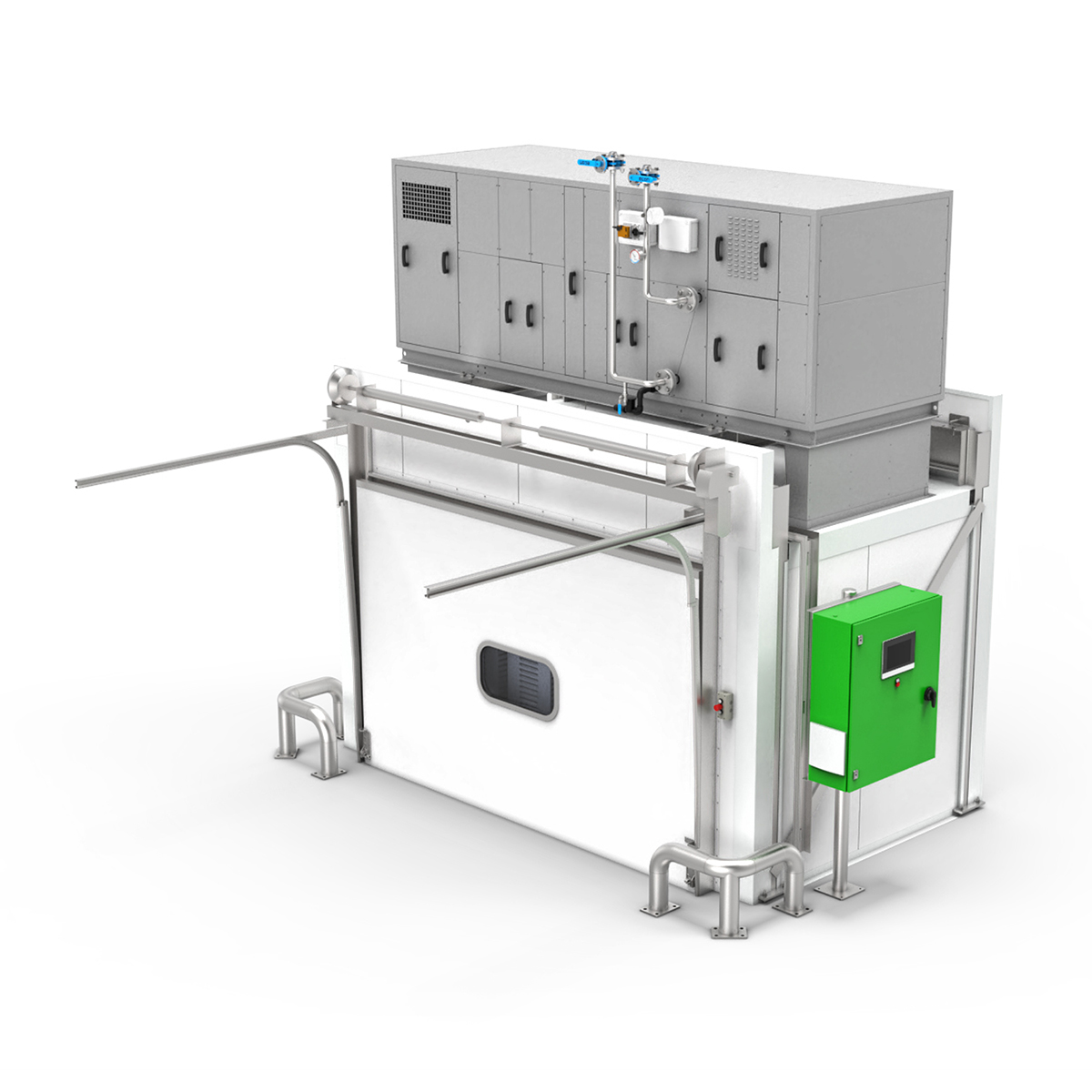

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental conditions to ensure the integrity of nutraceutical products like gummy vitamins and supplements in their jelly-like forms. This includes maintaining the appropriate temperature and humidity levels. Exposing these products to an open environment, where variables like temperature, humidity, and airflow cannot be controlled, could result in quality deterioration, contamination risks, and uneven drying.

Dry your functional gummies uniformly with a modular conditioning system

The OTC 400S NS Conditioning room, from Tanis, is a modular conditioning system for drying functional gummies and jellies. The design features an integrated air handling unit (AHUs) with a desiccant dryer to maintain a steady and uniform flow of air among the trays within the enclosed area, ensuring consistent drying of products. The closed system allows full control of the environment according to the parameters set for each batch of products and eliminates unwanted external conditions. Depending on production line requirements, the room can accommodate up to 840 moulding trays. Due to its precise control of the space conditions, retention times for products are reduced while allowing consistent reproduction of gummies and jellies.

Benefits

- Room capacity: 3 rows of 4 pallets

- Total capacity of 840 moulds per room

- Complete control of the room conditions, adjustable settings

- Less retention time

- Even distribution of airflow allows uniform drying