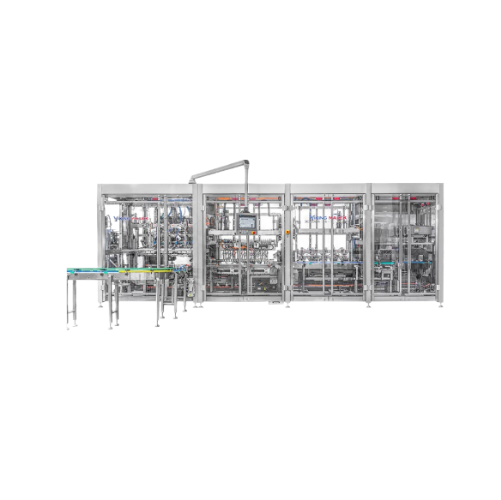

Topload cartoning system for efficient product packaging

Streamline your packaging line with this compact system that combines carton erecting, loading, and closing in one unit, ensuring high-speed, efficient operations and minimal footprint.

Erects, Loads, and Closes Cartons

The Topload MFM Cartoning Machine from Viking Masek combines three critical functions—carton erecting, product loading, and carton closing—into a single, compact unit designed for seamless integration into automated packaging lines. This versatile machine is engineered for diverse industries, including food, beverage, and medical, handling a wide range of product types such as powders, solids, and liquids. Its design is optimized for continuous high-speed operations, achieving up to 100 cartons per minute with precise servo-driven control and Siemens or Allen Bradley interface options. The machine offers flexibility in carton styles with options for lock-style, hot melt, or hot air systems, and features robust stainless steel construction with IP54-rated safety guarding for reliable operation in various environments. Additionally, it supports easy format changeovers and remote control for efficient management. The Topload MFM is tailored for optimal energy use, ensuring low operational costs while maintaining high performance in demanding production settings.

Benefits

- Enhances production efficiency by integrating erection, loading, and closing in a single unit.

- Maximizes floor space utilization with its compact design.

- Minimizes operational costs with energy-efficient drives and automation.

- Increases production flexibility with easy format changeovers and remote control options.

- Ensures reliable operation in diverse settings with robust, stainless steel construction.

- Applications

- Contract packaging, Treats, Snacks, Bakery, Cheese, Organic foods, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Powders, Candy, Pasta, Pet food, Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Vegetables, Poultry, Medical

- End products

- Steps before

- Carton Erecting, Product Preparation, Material Organizing

- Steps after

- Carton Closing, Palletizing, Distribution

- Input ingredients

- carton blanks, products for packaging, packaging materials

- Output ingredients

- fully erected cartons, packaged products, closed cartons

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 100 cpm

- Max. Bag Size

- 200 x 400 x 200 mm

- Min. Bag Size

- 100 x 100 x 25 mm

- Weight

- 2, 500 - 3, 500 kg

- Power supply

- 10 - 15 kVA

- Air pressure

- 6

- Automation

- Servo drives

- Material

- Stainless steel construction

- Controls

- Siemens or Allen Bradley

- Protection Class

- IP54

- Close Types

- Lock-style, hot melt or hot air systems

- Working mechanism

- Carton erector, product loading, closing

- Automation level

- PLC-controlled

- Changeover time

- Easy format change-over

- Cleaning method

- Excellent accessibility for cleaning

- Batch vs. continuous operation

- Continuous

- Speed control

- Max Speed 100 cpm

- Safety features

- Safety guarding

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Siemens or Allen Bradley controls

- IP54

- Machine footprint

- Compact

- Weight

- 2, 500 - 3, 500 kg

- Control panel type

- Siemens or Allen Bradley controls

- Construction material

- Stainless steel

- Bag size range

- Min

- Discharge method

- Carton closing

- Loading units

- Pickers, robots, rotary turrets, and others

- Frame sizes

- Different sizes for large carton range

- Lid closure

- Available

- Control panel type

- Siemens or Allen Bradley controls

- Integration possibilities

- Servo drives, Remote control, HMI adjustments

- Construction material

- Robust stainless steel

- Layout configuration

- Compact unit

- Carton setup styles

- Tray or fully closed carton

- Loading unit styles

- Pickers, robots, rotary turrets

- Closure options

- Lid closure

- IP rating

- IP54, IP65 washdown construction

- Carton closing

- Lock-style, hot melt or hot air systems

- Frame Sizes

- Different frame sizes for large cartons

- Damaged carton handling

- Damaged carton rejection

- Voltage and electrics

- Special electrics and voltages