Candy Depositing Equipment

Find production technology for depositing candies, and connect directly with leading machine manufacturers worldwide.

Depositing candy is a small in-between step before the extrusion or cooling process. After the candies are mixed and liquified, they need to be deposited in shaped trays. Oftentimes, the depositing process is combined with the extrusion process. To create a high-quality candy, you need to pay careful attention to the depositing process because cracking and hazing can occur. Candy depositing machines usually include a cooling system, and they focus on the scratch-free factor of the machine.

Which candy depositing technology do you need?

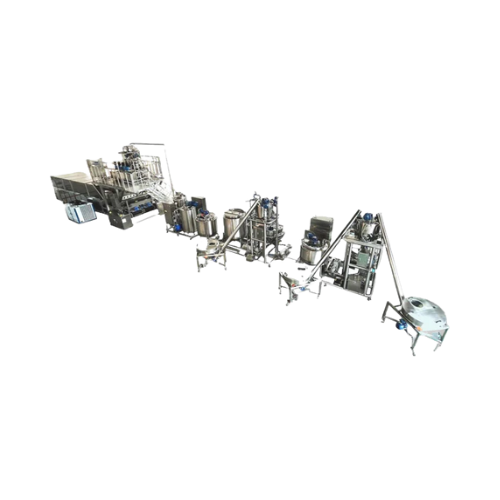

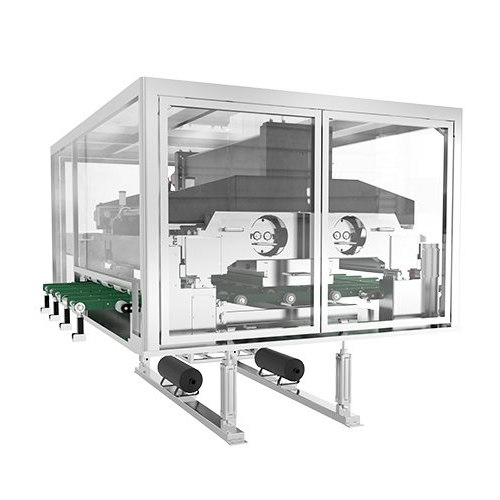

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Mini candy depositor for gummy production

Optimize your confectionery production with a compact depositor, delivering prec...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

Starch-free depositor for hard candy

Forming hard candies requires careful handling of syrups in order to avoid quality iss...

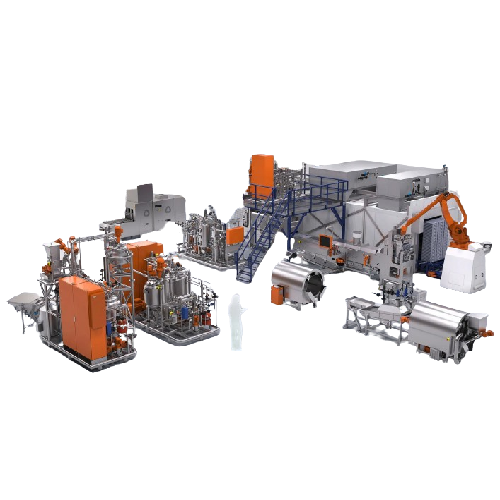

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Depositor for aerated masses and fat fillings

Enhance your confectionery production with a depositor that precisely handle...

High-viscosity mass depositor

Efficiently deposit high-viscosity masses like caramel and jam with precision, while the integ...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Mallow make up line equipment

Achieve diverse marshmallow designs with precision using advanced extrusion and coating techno...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Weight-accurate depositor for confectionery refinement

Achieve precise filling and refinement of biscuits and confections...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

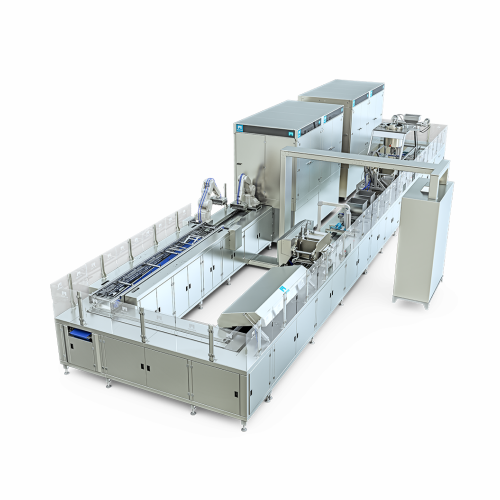

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

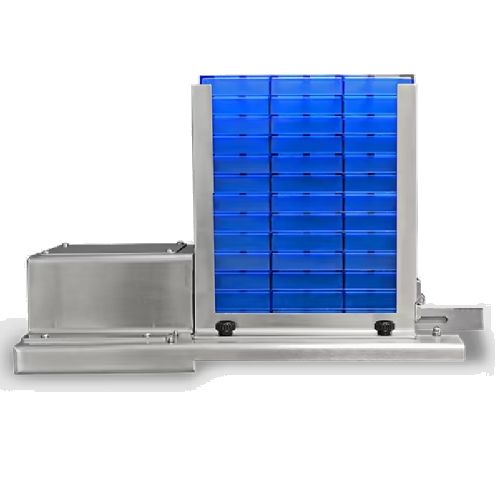

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

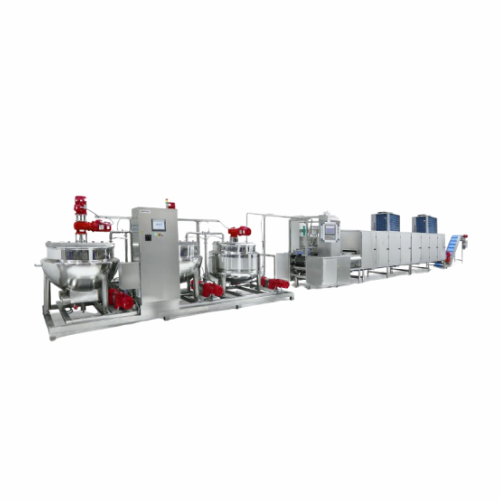

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Mobile depositor of tiger wash

Manufacturers of tiger bread and other similar consumables often find that achieving perfect ...

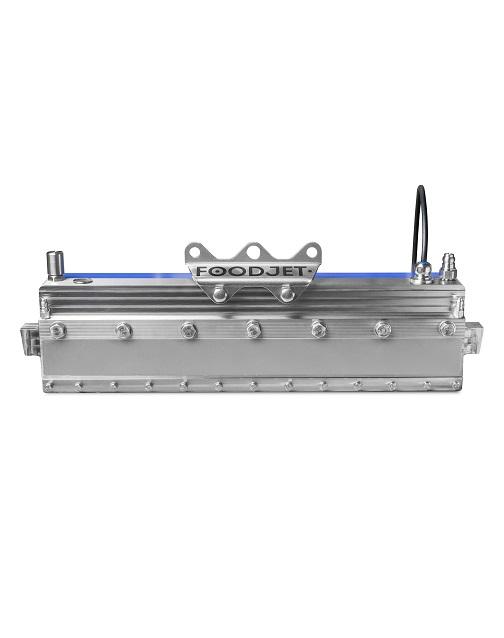

Starch-free depositor systems for jelly

Traditional depositing for jellies and gummies requires the use of starch moulds. T...

Starch-free depositor for soft confectionery

Soft confectionery such as toffees, fondants, fudges and jellies have traditi...

Starch-free depositor for lollipops

Traditional high volume continuous lollipop production can lead to inconsistent product...

In-line colour or flavour addition for confectionery

The addition of colourings and flavourings increases value and quali...

Production machine for deposited candies and jellies

For smaller production volumes, fully automated depositors for produ...

Laboratory confectionery depositors

When designing new confectionery products, the ability to experiment on lab-scale equip...