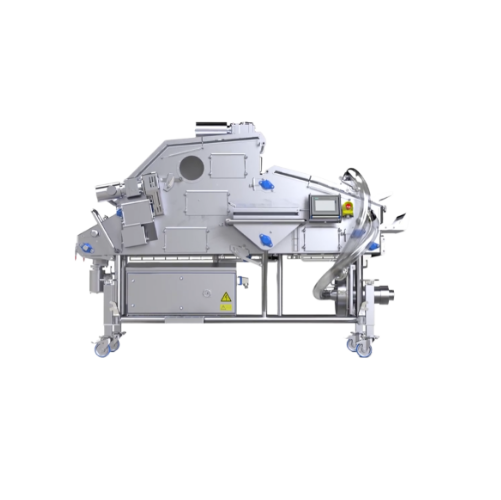

Preduster for fine-grain coating in food processing

Ensure your products receive a perfect, consistent fine-grain coating with advanced control over the coating process, significantly enhancing texture and appearance while minimizing waste.

Applies and Controls Fine-Grain Coating

The alco Preduster ABM PRO & VARIO-FLIP from alco food-machines is engineered to deliver precise and consistent coating for a wide range of food products. Utilizing a dual-belt system, the equipment applies fine-grained powders, ensuring an even and controlled application on products like fish sticks, chicken tenders, and plant-based nuggets. The Vario-Flip feature adds versatility by flipping products for enhanced coating absorption, ideal for replicating a handmade finish on delicate or irregular items.

Suitable for the bakery, confectionery, pet food, and plant-based protein industries, this machine excels in high-speed, continuous production environments. It allows easy adjustment of coating quantities through a user-friendly PLC operating system, which integrates seamlessly with production lines. The alco Preduster also minimizes energy consumption with an efficient stainless steel drive system, and its stainless steel construction ensures durability and compliance with hygiene standards.

Operators benefit from minimal dust generation and efficient cleaning, thanks to its easy-access design and integrated cleaning systems. Whether you need precise flour placement on pastries or consistent spice application on chicken parts, the alco Preduster ABM PRO & VARIO-FLIP offers customizable engineering support to meet your specific processing needs.

Benefits

- Ensures consistent product quality with precise coating application.

- Increases production efficiency with high-speed continuous operation.

- Reduces waste through effective dust containment and excess material removal.

- Simplifies cleaning and maintenance, enhancing operational uptime.

- Adapts easily to diverse product requirements with adjustable settings.

- Applications

- Seafood, Ready meals, Candy, Potatoes, Pet food, Convenience food, Bakery, Confectionery, Meat, Plant-based food, Plant-based protein, Vegetables, Poultry, Pastries

- End products

- Sweet wine gums, Herb-coated pet treats, Seasoned chicken parts, Sugarcoated donuts, Crumbed beef strips, Breaded fish fillets, Plant-based nuggets, Coated confectionery items, Calamari rings, Vegetable patties, Chicken tenders, Spice-coated potato wedges, Floured pastries, Fish sticks, Quark balls

- Steps before

- Grinding, Mixing, Portioning, Slicing

- Steps after

- Frying, Cooking, Tray Sealing, Packing

- Input ingredients

- flour, spices, powder, sugar, fine-grained materials, seafood, pastries, candy, plant-based food, vegetables

- Output ingredients

- coated products, floured fish filets, predusted convenience food, sugared products, seasoned products, homemade style coated products, chicken tenders, fish sticks, irregularly shaped products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Automation

- PLC-controlled

- Belt speed

- up to 29 m/min

- Coating method

- Belt process

- Material return system

- Integrated

- Construction Material

- Stainless steel

- Cleaning method

- Easy-to-clean design

- System control

- Touch panel with recipe management

- Pressing and Vibrating Devices

- Adjustable

- Excess material removal

- Air knife with blower system

- Height adjustment

- Handwheel operated

- Working mechanism

- Conveyor belt system with sprinkling action

- Integrated steps

- Adjustable pressing, vibration, and blower systems

- Automation level

- PLC-controlled with touch panel

- CIP/SIP

- Easy-to-clean design

- Changeover time

- Tool-free changeover

- Cleaning method

- Easy to empty and clean

- Batch vs. continuous operation

- Continuous

- Air incorporation control

- Adjustable air knife system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Grain Size Compatibility

- Fine-grained materials (e.g., flour, spices, sugar)

- Coating Uniformity

- Complete and even coating

- Product Type

- Pastries, seafood, plant-based food, vegetables

- Material Flow Control

- Adjustable pressing, vibration, and blower systems

- Coating Process

- Vario-Flip for successive 180° flips

- Sensitivity of Products

- Suitable for sensitive molded products

- Machine Material

- Stainless steel

- Belt System

- Two systems of belts (lower and upper)

- Control Panel

- Touch panel with PLC operating system

- Height Adjustment

- Spindle height adjustment with handwheel

- Material Storage Container

- Easy to fill

- Vibration,Pressing Devices

- Adjustable

- Optional Vibrating Plate

- For coarser coating media

- Air Knife

- Adjustable blower system

- Control panel type

- Touch panel with PLC

- Integration possibilities

- Recipe management and smart controls

- Pressing adjustment

- Adjustable pressing devices

- Vibration control

- Adjustable vibration devices

- Belt speed

- Up to 29 m/min

- Flip height

- Tool-free adjustment

- Machine height

- Handwheel adjustment