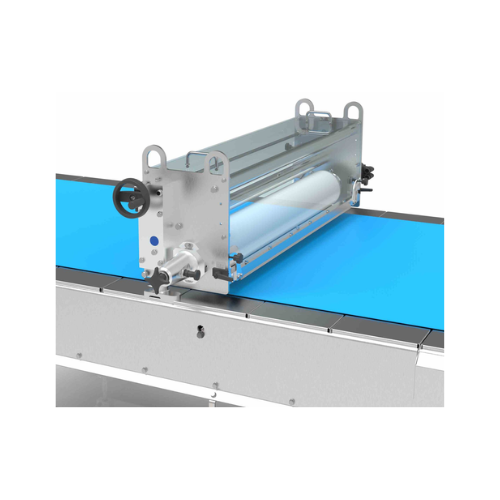

Pressing roller for cookie thickness adjustment

Ensure consistent cookie thickness and unique product patterning with a high-speed roller ideal for streamlining confectionery and baked goods production lines.

Compresses and Patterns Baked Goods

The Meincke 3388 pressing roller from Bühler is engineered for precision in compressing cookies, biscuits, cakes, and other baked goods. This equipment is distinguished by its servo-driven adjustable band speed, optimizing for varying production needs without multiple rollers, thereby streamlining operations and reducing costs. It’s ideally suited for continuous, high-speed processing lines, efficiently handling a range of end products such as chocolate chip cookies and shortbread biscuits. The roller’s quick-release mechanism allows for rapid changeovers, enhancing productivity. Its design simplifies cleaning and maintenance with tool-free removable parts, supporting compliance with latest hygiene standards. The pressing roller can be integrated into diverse production lines and customized with additional rollers for unique patterning, meeting the versatile needs of biscuit manufacturers and confectionery producers.

Benefits

- Increases production efficiency with adjustable speed control, reducing the need for multiple rollers.

- Enhances product consistency and quality by ensuring uniform thickness.

- Minimizes downtime with quick-release features for fast product changeovers.

- Simplifies maintenance and adheres to hygiene standards with easy-to-clean removable parts.

- Allows versatile product design with optional patterning capabilities for added product differentiation.

- Applications

- Cookies, Biscuits, Baked goods, Snacks, Confectionery, Cakes

- End products

- Layer cakes, Butter cookies, Chocolate chip cookies, Muffins, Shortbread biscuits, Sugar cookies, Crackers, Gingerbread cookies, Sponge cakes, Cream-filled donuts, Fruit-filled pastries

- Steps before

- Dough prep, extrusion, shaping, Mixing, Raw material preparation

- Steps after

- Baking, Cooling, buffering, Filling, decorating, Packing, Palletizing

- Input ingredients

- cookie dough, biscuit dough, cake dough

- Output ingredients

- compressed cookies, compressed biscuits, compressed cakes, patterned cookies, patterned biscuits, patterned cakes

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Adjustable band speed

- Low to high

- Pressing roller thickness

- Customizable

- Servo drive

- Included

- Quick release function

- Yes

- Cleaning method

- Tool-free removal

- Scraper options

- Various available

- Automation level

- Manual / PLC-controlled

- Changeover time

- Quick release function for fast product changeover

- CIP/SIP

- Easy cleaning due to removable parts

- Cleaning method

- Manual removal of parts for cleaning

- Energy efficiency

- Optimized factory footprint saving costs

- Batch vs. continuous operation

- Continuous with adjustable band speed

- Abrasion resistance

- Yes/No

- Biological compatibility

- Yes/No

- Cleanability

- Easy cleaning

- Corrosive resistance (e.g. acids)

- Yes/No

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compression thickness

- Adjustable

- Machine footprint

- Compact design

- Control panel type

- Touchscreen interface

- Discharge method

- Adjustable scraper system

- Adjustment method

- Servo-driven band speed

- Cleaning method

- Tool-less part removal

- Band speed adjustability

- Low to high speeds

- Quick release function

- Available for rollers and scrapers

- Roller pattern customization

- Unique patterns available

- Tool-free maintenance

- Parts removable without tools