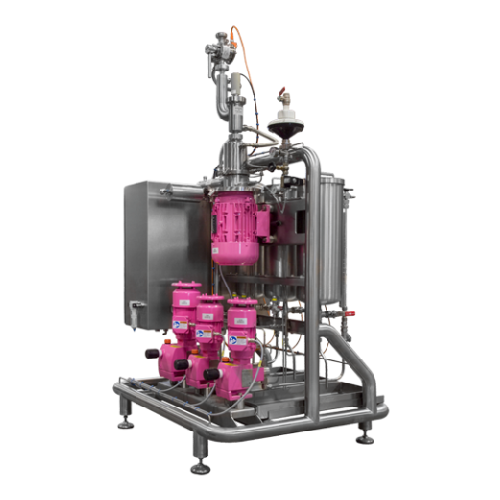

Dynamic mixer for bakery and confectionery applications

Enhance product consistency and reduce downtime with this advanced mixer designed for seamless in-line integration, handling temperature and shear-sensitive ingredients without compromising quality.

Mixes and Blends Liquids Continuously

The CFA-INJECTION/DYNAMIC MIXER from Tanis Food Tec is tailored for precise in-line mixing in bakery and confectionery operations. This system excels at integrating color, flavor, and various liquid products into a primary liquid flow, employing continuous dynamic mixing to replace traditional batch processes. With applications in producing cake batter, dough, syrups, and flavored creams, it offers distinct advantages in handling temperature and shear-sensitive formulations. The mixer’s CIP capability ensures easy cleaning and seamless change-overs between recipes, minimizing downtime. Designed for integration into automated production lines, it employs flow measurement for accurate recipe management, enhancing both efficiency and product consistency.

Benefits

- Enhances product consistency through precise in-line mixing.

- Reduces waste and downtime by eliminating batch processes.

- Adapts easily to varying viscosities, preserving product integrity.

- Supports efficient recipe change-overs, optimizing production flexibility.

- Ensures thorough cleaning with fully CIP-compatible design.

- Applications

- Bakery products, Confectionery, Liquid formulations

- End products

- Flavored creams, Glazes, Liquid fillings, Fondant, Syrups for confectionery, Cake batter, Dough for pastries

- Steps before

- Liquid Measurement, Ingredient Preparation

- Steps after

- Product Cooling, Product Packaging

- Input ingredients

- color, flavor, liquid products, primary liquid flow

- Output ingredients

- mixed liquid product

- Market info

- Tanis Food Tec is known for designing and manufacturing custom-engineered food processing equipment, specializing in innovative solutions for the confectionery, bakery, and dairy industries, with a reputation for quality, precision, and reliability in delivering tailored production lines.

- Mixing Method

- Dynamic Mixing

- Application

- Temperature and Shear Sensitive

- Integration

- In-line Continuous

- Changeover Flexibility

- Easy change-overs between recipes

- Cleaning Method

- Fully CIP-able

- Working mechanism

- Dynamic mixing

- Process integration

- Color and flavor mixing

- Flow type

- Inline Continuous

- Shear sensitivity

- Temperature and shear sensitive compatibility

- Changeover time

- Easy recipe changeovers

- CIP/SIP

- Fully CIP-able

- Viscosity range

- Low to high viscosity

- Cleanability

- CIP-able

- Footprint

- Compact

- Mixing capability

- Inline mixing

- CIP capability

- Fully CIP-able

- Temperature sensitivity

- Supports temperature-sensitive products

- Shear sensitivity

- Supports shear-sensitive products

- Recipe change-over

- Easy change-overs

- Control panel type

- PLC-controlled

- Integration possibilities

- Flow measurement

- Automation level

- Inline continuous operation