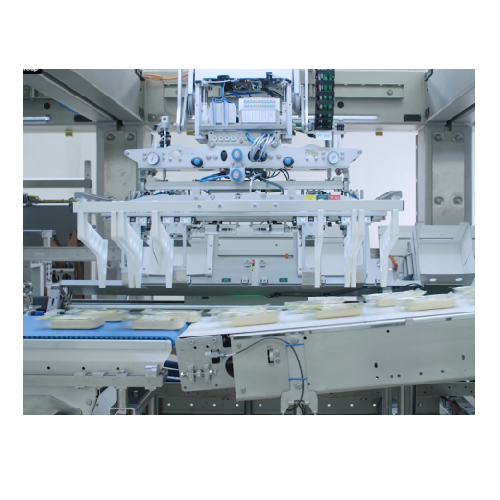

Case packer for diverse packaging needs

Optimize your production line with this modular case packer, designed to handle diverse products seamlessly while ensuring efficiency and reducing waste through robotics-assisted processes.

Automates Erecting, Filling, and Closing Operations

The Schubert Case Packer, including the Comfort Feeder, offers unmatched flexibility in packaging operations. Utilizing robotic-assisted technology, it excels in erecting, filling, and closing processes for industries like food, beverages, and cosmetics. With its modular design, the system integrates seamlessly into high-speed production lines and supports a range of product types from solid to liquid. The Power Compact model optimizes warehouse space by feeding flat blanks directly from pallets, achieving up to 60 erected packs per minute. Its automation platform allows for continuous operation, quick format changes, and reduces material waste by up to 25%. The Transmodul ensures precise, efficient product transport, and 3D-printed robotic tools minimize wear and tear. Suitable for medium to large-scale manufacturers, this equipment meets industry standards and offers CIP for easy maintenance, ensuring a reliable packaging solution with customizable options to suit specific production needs.

Benefits

- Enhances production efficiency with quick format changeovers and plug-and-play setup.

- Minimizes material waste, cutting packaging consumption by up to 25%.

- Reduces manual labor through autonomous operation for up to six hours.

- Supports seamless integration into existing production lines with modular design.

- Ensures gentle product handling with custom 3D-printed robotic tools.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Bakery products, Dairy products

- End products

- Lip gloss tubes, Face masks, Wrapped candies, Yogurt cups, Energy drinks, Pet food pouches, Dog treats, Small beverage bottles, Packaged bread loaves, Soap bars, Breakfast cereals, Ready-to-sell packaged chocolate bars, Lip balm sticks, Bottled juices

- Steps before

- Product Filling, Grouping Products, Product Preparation

- Steps after

- Shipping, Distribution, Logistics

- Input ingredients

- glass, plastic, cardboard, bottles, bags, cans, blister packs, cartons, flat blanks, unsorted products

- Output ingredients

- shipping cartons, erected packs, RSC cartons, trays, trays with lids, wrap-around cartons, pouches, aforementioned packaging types

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Packaging Speed

- Up to 60 packs per minute

- Automation Level

- Fully automatic

- Format Changeover

- Quick format changeovers with plug, play

- Material Handling

- Cardboard, glass, plastic, bottles, bags, cans, blister packs, cartons

- System Integration

- Modular design for integration into complex systems or as a stand-alone

- Erecting Technology

- Robot-assisted top-loading and A6 carton erector

- Feeder System

- Comfort Feeder, direct from pallet

- 3D Printing Capability

- In-house with PARTBOX system

- Robotic Tools

- Customised and 3D printed for different packaging types

- Product Types

- Food, confectionery, beverages, cosmetics, pet food

- Transport System

- Transmodul transport robot

- Space Efficiency

- Power Compact concept for limited space environments

- Packaging Materials

- Cardboard with high recycling rate, sustainable designs

- Changeover Time

- No start-up phase post format change

- Carton Styles

- Trays, trays with lids, wrap-around cartons, RSC cartons

- Automation Level

- PLC / SCADA

- Changeover Time

- Fast format changeover via plug, play

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Easy to clean with gentle handling

- Energy Efficiency

- Optimised robotic movement

- Integration Capability

- Stand-alone or integrated into a complete line

- Cardboard Compatibility

- Yes

- Glass Handling Capability

- Yes

- Plastic Handling Capability

- Yes

- Metal Handling Capability

- Yes

- Robustness with Heavy Products

- Yes

- Breakable Surface Handling

- Yes

- Liquid Contents Handling

- Yes

- 3D Printed Parts Compatibility

- Yes

- Density/Particle Size

- 0

- Machine footprint

- Up to one third less space required

- Container type

- Bottles / Bags / Cans / Cartons

- Modular design

- Yes

- Robot-assisted top-loading

- Yes

- Transport method

- Transmodul transport robot

- Blank feeding method

- Pallet loading with Comfort Feeder

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Seamlessly with existing lines

- Footprint

- Compact and space-saving

- Adaptability to different carton styles

- Trays, wrap-around, RSC

- Format changeover

- Plug, Play

- Custom robotic tools option

- Customizable for various shapes and weights

- 3D printing capability

- PARTBOX 3D printing system