Gummy Depositing Equipment

Depositing jelly and gum mixtures into molds is an intricate process. The viscosity of cooked syrups makes them challenging to handle and dose, whether gelatin-based or pectin-based. Advanced depositing machines for gummies prevent extra dripping from the nozzles once the mold is filled. By controlling tailing, accurate depositors reduce wastage and produce high-definition gummies.

What are you making?

Which gummy depositing technology do you need?

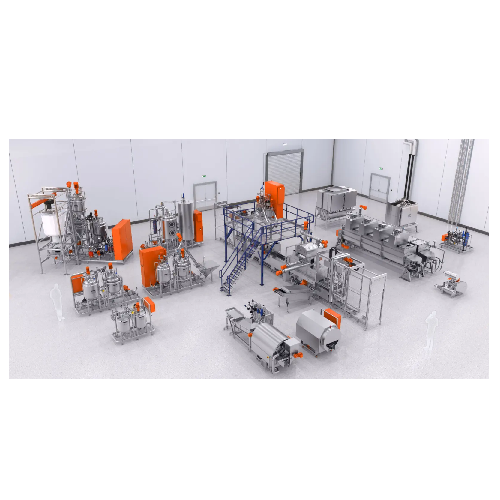

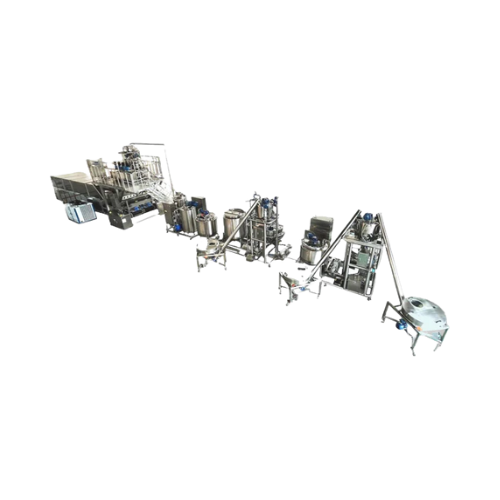

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Fully-automatic non-starch production line for gummies

Optimize your gummy production with a high-capacity, fully-automat...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

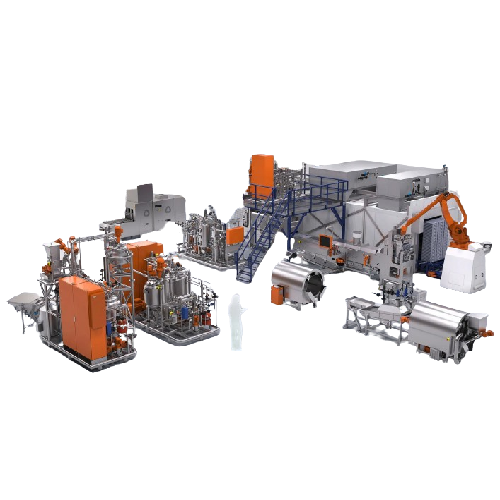

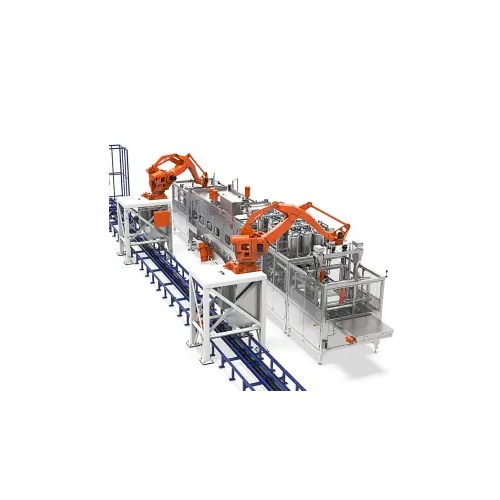

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

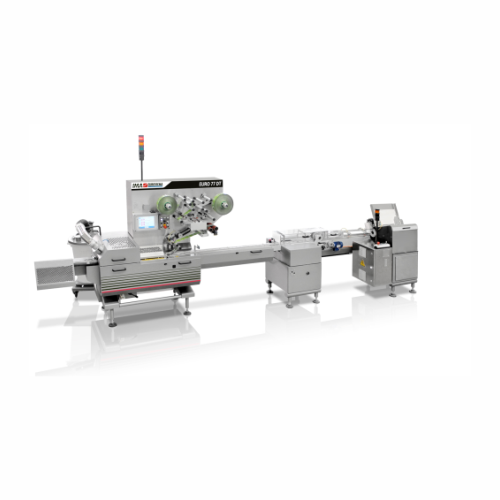

Candy packaging solution for gummies and hard candies

Maximize your confectionery efficiency with high-speed packaging so...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

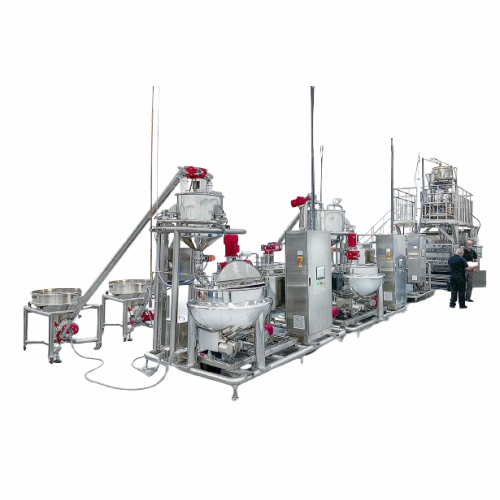

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

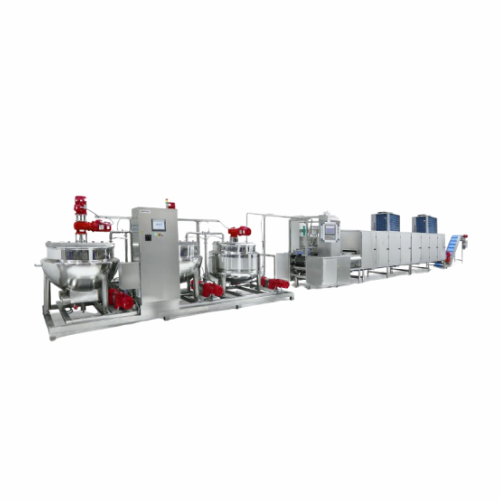

Small automatic gummy line

Streamline your gummy production with a compact system designed to deliver precision deposits and...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Mini candy depositor for gummy production

Optimize your confectionery production with a compact depositor, delivering prec...

Gummy candy depositor for precision manufacturing

Achieve consistent gummy size and shape while maintaining precise weigh...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

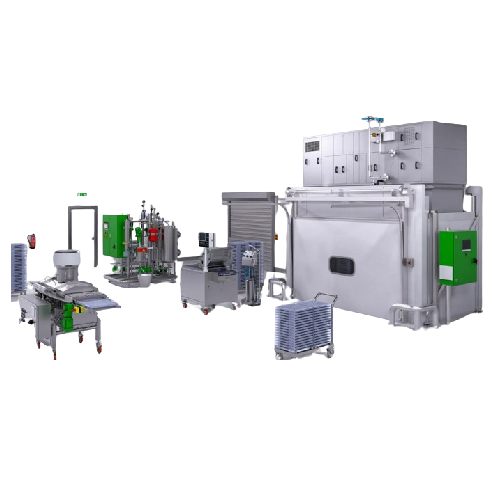

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Gum slabs flow wrapping solution

Streamline your confectionery production with precision-engineered portioning and wrapping,...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...