Gummy Cooking Equipment

Bears, worms, snakes, it doesn’t matter what shape they have because these chewy and delicious gummies drive people of all ages crazy. The first step to making these sweet treats is the gummy cooking process which can last a few hours until the gelatin-like paste is formed. When cooking gummies, producers use different cookers to dissolve the sugar slurry and convert it to syrup. After acquiring all the ingredients, place them into a kettle until they reach the desired temperature to make the gelatin solution which will later be turned into gummies.

What are you making?

Which gummy cooking technology do you need?

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Pre-cooking and final cooking for candy production

Optimize your candy production with a versatile cooker designed to han...

Laboratory unit for small quantity production and r&d

For product developers needing precise control and flexibility, thi...

Integrated process system for hard caramel production

Optimize your candy production with a fully integrated system desig...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

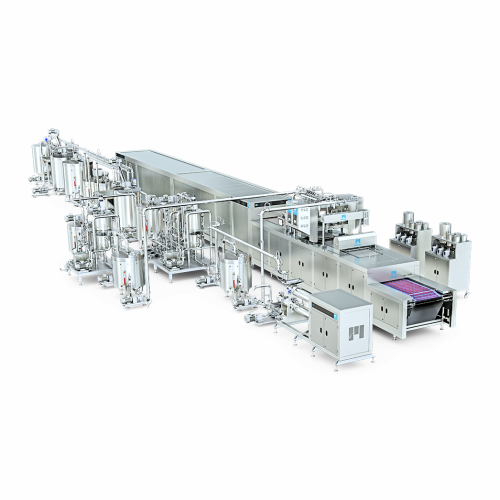

High-capacity non-starch gummy and jelly production line

Boost your gummy production efficiency with a seamless, high-cap...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

High output confectionery kitchen technology

Elevate your confectionery production with seamless processes that ensure pre...

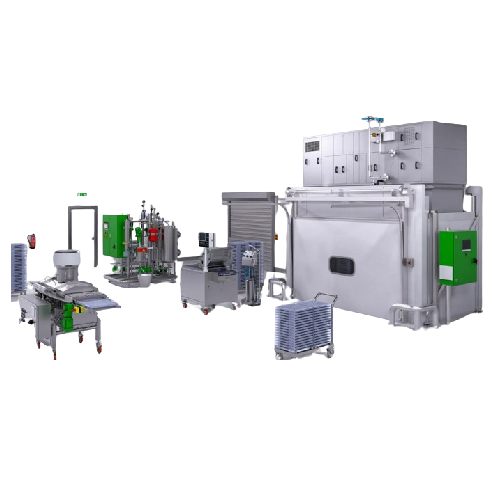

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Soft candy production line

Optimize your candy production with a versatile line that efficiently handles everything from car...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Batch cooker for confectionery production

Achieve consistent confectionery texture and flavor with a flexible cooking solu...

Caramelization system for industrial confectionery production

Achieve precise caramelization and cooking of sensitive co...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Lab cooking and forming extruders for r&d

Optimize your R&D processes by testing new recipes and improving formulatio...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Continuous cooking system for jelly and marshmallow production

Elevate your confectionery production with a system desig...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...