Making Thc Extract

Find innovative production technology for making thc and connect directly with world-leading specialists

The cannabis industry is one of the fastest growing in the world with a revenue of $20.47 billion in 2020 which is expected to soar up to $197.74 billion in 2028. The famous cannabis substance that causes marijuana's psychological effects is THC and it was first isolated in 1964. There are two methods of extracting THC from cannabis: solvent-based and non-solvent extraction. Each technique requires different THC oil extraction equipment.

Tell us about your production challenge

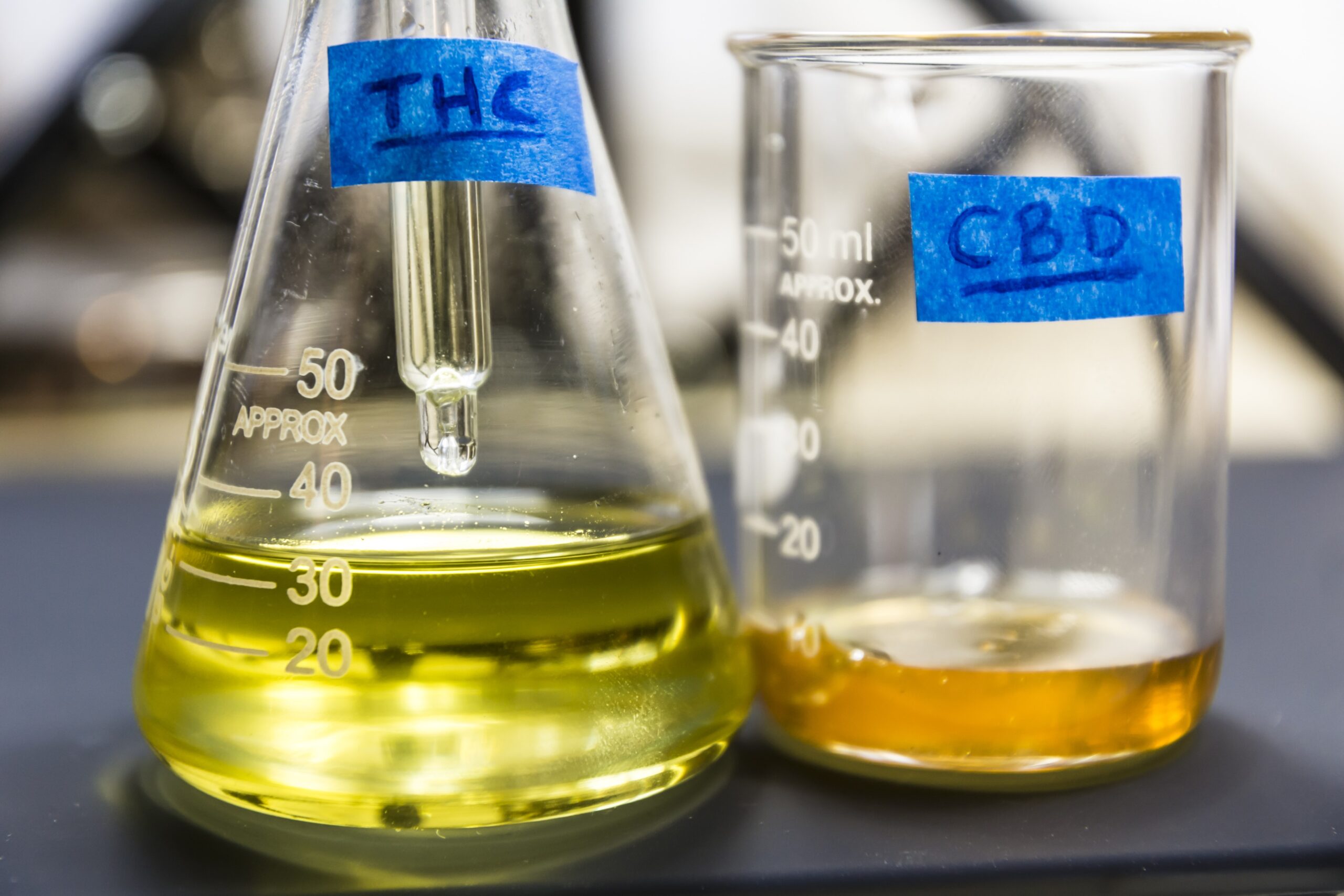

CBD and THC: what is the difference?

CBD, short for cannabidiol, and THC, or delta-9-tetrahydrocannabinol, are the two most common substances in cannabis. They affect receptors that release neurotransmitters in the brain. THC, the most psychoactive molecule, induces the feeling of being high.

On the other hand, CBD is non-psychotropic and associated with well-being, and therefore a natural treatment for conditions such as arthritis, Crohn’s disease, diabetes, etc. THC is sourced from marijuana, while CBD, which can be extracted from both, is more commonly sourced from hemp that contains 0.3% or less THC.

The differences between the effects of the two substances lay in their molecular distinction. Although they have the same chemical formula, they are composed of 21 carbon atoms, 30 hydrogen atoms, and two oxygen atoms, the atoms are constructed differently.

THC oil extraction equipment and processes

Two main techniques for cannabis extraction are solvent-based and solventless extraction methods. Solvent-based methods rely on chemicals such as ethanol, hypercarbons, CO2 or oils, to dissolve cannabinoid trichomes from the plant. On the other hand, solventless techniques use agitation methods and machines with low heat and pressure without any chemical solvent involved, to extract trichomes from the plant.

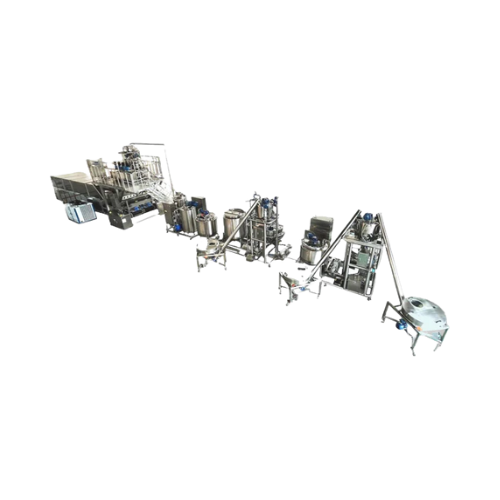

The solvent-based extraction method using ethanol is a popular choice for being efficient and safe. In the extraction agent, which is chilled in an inline chiller to as low as -40℃, the previously soaked cannabinoid compounds are extracted from the biomass. Subsequently, a filtration skid filters out suspended particulates and adsorbents and a falling film evaporator vaporizes ethanol from the oil. During decarboxylation, the solvent-free cannabinoid molecules is converted into consumable versions. Finally, the purified THC is separated from the crude oil in a rolled film distillation.

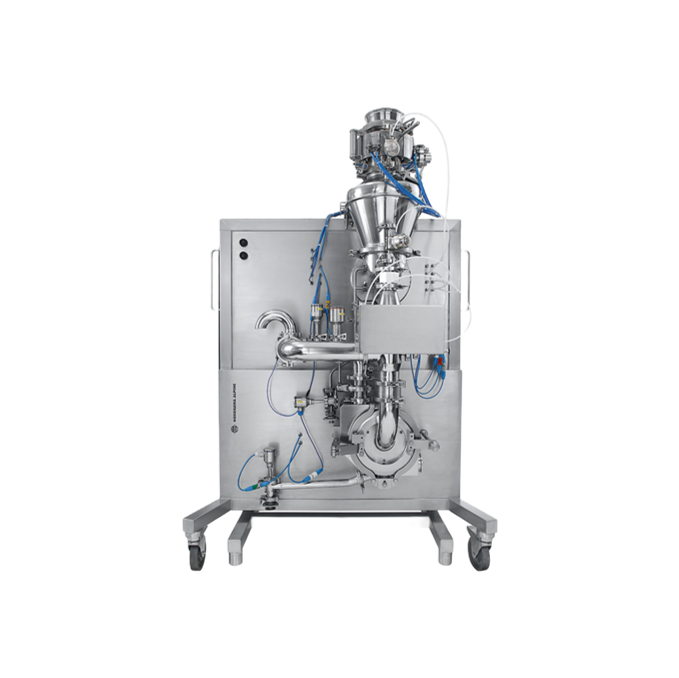

The THC oil extraction equipment used for the solventless method known as mechanical separation is a hash oil extractor machine, which separates the cannabinoid-rich trichomes from the biomass by using water, ice and an agitational force. The trichomes broken off the plant float into the water and are filtered out through screening bags.

Another favored solventless processing method is similar to cold-pressed oil production, bearing the same name. The oil is extracted using a cold press machine by crushing the pre-cooled plant material. This method is considered a more natural way of processing biomass, which caters to enjoyers of the pure plant flavor.

Hemp cultivation and the environment

The cultivation of hemp has significant environmental benefits. Namely, the plant grows fast, requires no pesticides, is drought-resistant, and nurtures the soil by returning 60% of the nutrients it takes while growing. Therefore, hemp improves soil fertility but suppresses the growth of weeds. Moreover, hemp is a culture ΔCO2 negative, which means it removes more CO2 from the atmosphere than it emits.

Hemp can substitute plastic such as grocery bags and bottles, polyester in textiles, and hemp seed oil can be used as biomass fuel. Finally, hemp paper is an excellent alternative to prevent deforestation which has several terrible side effect such as climate change, soil erosion, and displacement of animals and native tribes. Trees take decades to grow – this means we cut them down faster than we can replace them – but the hemp plant matures in a couple of months. China, Romania, Germany, Ecuador, Colombia and Lithuania are some of the most prominent faces on the global hemp industry scene.

Processing steps involved in THC making

Which thc technology do you need?

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

Solventless trichome separation for bubble hash production

Achieve high-quality, solventless extracts with superior tric...

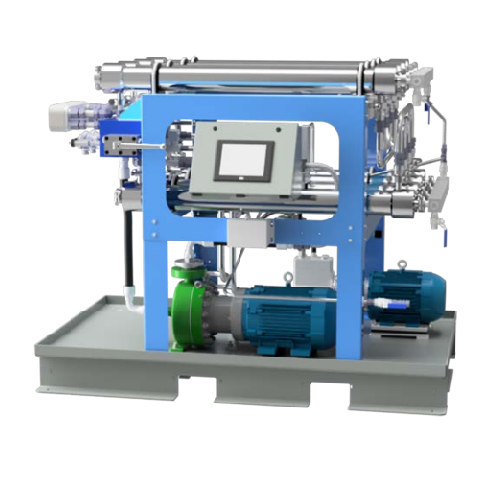

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

Cannabis and hemp short path distillation system

Achieve optimal cannabinoid purification with continuous high-volume dist...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Membrane nanofiltration for cannabis and hemp processing

Optimize your extraction processes with advanced nanofiltration,...

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced n...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

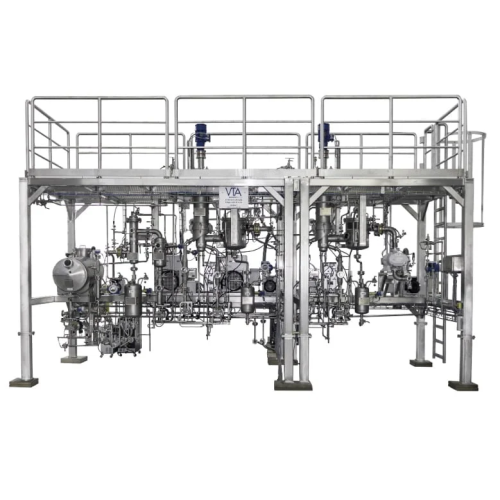

Custom distillation builds for cannabis processing

Achieve precise cannabinoid separation and purity in large-scale disti...

Industrial-scale cannabis distillation system

Achieve up to 99% cannabinoid purity effortlessly with an industry-standard ...

Solventless terpene extractor for cannabis processing

Preserve the most volatile aromatic compounds during extraction, en...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Cannabis and hemp distillation system

Achieve up to 99% cannabinoid purity with high-throughput, continuous distillation th...

Hydrocarbon extraction system for cannabis extraction

Achieve high-efficiency extraction with precise solvent control, op...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

Hydrocarbon extraction system for cannabis industry

Optimize your extraction process with cutting-edge technology designe...

Hydrocarbon extraction system for cannabis

Optimize your cannabis concentrate production with a flexible hydrocarbon extra...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

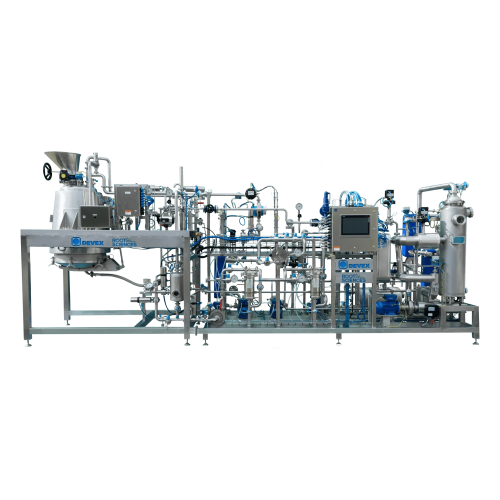

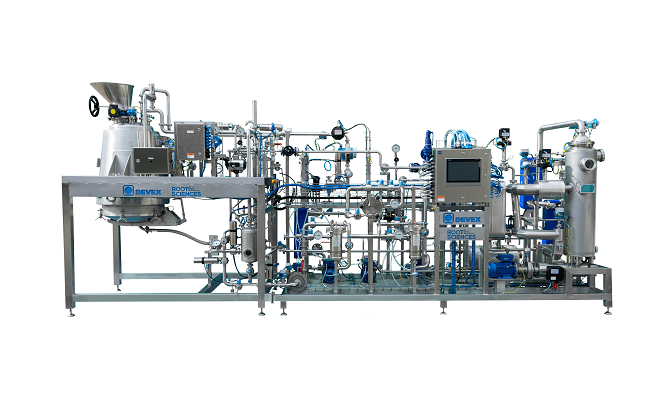

High capacity cannabis cryo-ethanol extraction system

Accelerate your extraction efficiency with a system that drasticall...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...