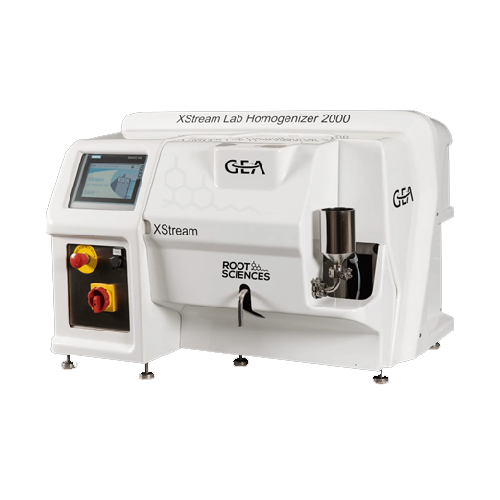

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced nanoemulsification technology, ideal for creating water-soluble formulations and enhancing bioavailability.

Creates Stable, Bioavailable Nanoemulsions

The XStream from Root Sciences is a high-pressure nanoemulsification system specifically engineered for the cannabis and hemp industries. Employing NiSoX-Valve technology, it creates ultra-fine nanoemulsions with fewer passes than conventional equipment, enhancing bioavailability and stability in products such as cannabis-infused beverages and edibles. Operating at up to 2,000 bar, it can produce up to 144,000 servings per 8-hour shift, making it an industrial-grade solution for large-scale operations. Its automated pneumatics allow for precise control and continuous production, ensuring consistent quality. Designed for seamless integration, the XStream supports CIP procedures, minimizing downtime for maintenance. Available with optional upgrades such as a heat exchanger and high shear mixer, it complies with cGMP standards, offering reliable performance in demanding environments.

Benefits

- Enhances product bioavailability and stability for superior consumer experiences.

- Increases production efficiency with high throughput of up to 144,000 servings per shift.

- Saves time and resources with Clean-In-Place (CIP) capabilities for efficient maintenance.

- Complies with cGMP, ensuring adherence to pharmaceutical production standards.

- Reduces manufacturing costs by minimizing ingredient usage and process iterations.

- Applications

- Beverages, Supplements, Flavored beverages, Nutraceuticals, Bioactive compounds, Edibles, Hemp products, Food and beverage, Essential oils, Cannabis products, Pharmaceuticals

- End products

- Fast-acting thc oral sprays, Flavored cannabis-infused beverages, Soluble cbd capsules, Liquid nutraceutical formulations, Cannabis-infused gummies, Bioavailable vitamin supplements, Nanoemulsified essential oils, Essential oil blends, Clear cannabis tinctures, Water-soluble hemp oil

- Steps before

- Coarse Emulsification, Homogenization, Preparation of Feed Material

- Steps after

- Packaging, Storage, Formulation into Beverages or Edibles

- Input ingredients

- cannabis oil, water, compressed air, formulations

- Output ingredients

- cannabis nanoemulsions, flavorless nanoemulsions, clear nanoemulsions, high-load nanoemulsions

- Market info

- Root Sciences is known for providing high-quality extraction, distillation, and other processing equipment for the cannabis and hemp industries, offering solutions for creating purified concentrates and extracts, emphasizing efficiency and innovation.

- Max Flow Rate

- 10.8 L/h

- Production Rate

- 16k (flavorless) - 18k (clear) 10 mg servings/h

- Pressure

- 2, 000 bar

- Motor Power

- 1.85 kW

- Electrical Options

- 3Φ 200 V, 50 Hz / 3Φ 220 V, 50-60 Hz / 3Φ 400 V, 50 Hz / 3Φ 460 V, 60 Hz

- Required Utilities

- Compressed air (10 bar)

- Feeding Hopper Volume

- 0.4 L

- Minimum Sample Volume

- 30 mL

- Dimensions (LxWxH)

- 940 x 617 x 640 mm

- Weight

- 170 kg

- Optional Upgrades

- 2 L jacketed feeding hopper, heat exchanger, temperature sensors, documentation for cGMP/CFR 21/GAMP, IKA T-25 high shear mixer package

- Flow rate

- 10.8 L/h

- Pressure

- 2, 000 bar

- CIP/SIP Procedures

- CIP

- Automation Level

- Pneumatically regulated homogenizing valves

- Batch vs. Continuous Operation

- Continuous

- Motor Power

- 1.85 kW

- Electrical Options

- 3Φ 200 V, 50 Hz / 3Φ 220 V, 50-60 Hz / 3Φ 400 V, 50 Hz / 3Φ 460 V, 60 Hz

- Cleanability

- Proven homogenization and maintenance procedures

- Temperature Control

- Optional upgrades with temperature sensors

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- cGMP/CFR 21

- Documentation

- cGMP/CFR 21/GAMP

- Machine Footprint

- 940 x 617 x 640 mm

- Weight

- 170 kg

- Feeding Hopper Volume

- 0.4 L

- Minimum Sample Volume

- 30 mL

- Optional Upgrade

- Feeding Hopper

- Optional Upgrade

- Heat Exchanger

- Optional Upgrade

- Temperature Sensors

- Feeding hopper volume

- 0.4 L / 2 L (optional)

- High shear mixer package

- IKA T-25 (optional)

- Heat exchanger for product outlet

- Optional

- Temperature sensors for inlet/outlet

- Optional