Making Cbd Oil

Find innovative production technology for making cbd oil and connect directly with world-leading specialists

While still forbidden in many countries, there's plenty of room for the use of cannabidiol, or CBD. It’s the second most present active ingredient of the cannabis plant and, no, it won’t get anybody high. What it does, really, once it’s out of the CBD oil processing equipment, is to provide many well-being and health benefits. They go from treating depression and anxiety to relieving pain and unmanageable diseases' symptoms.

Technology picks for cbd production

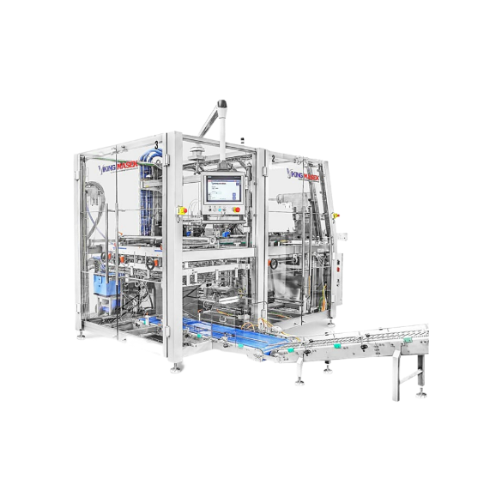

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

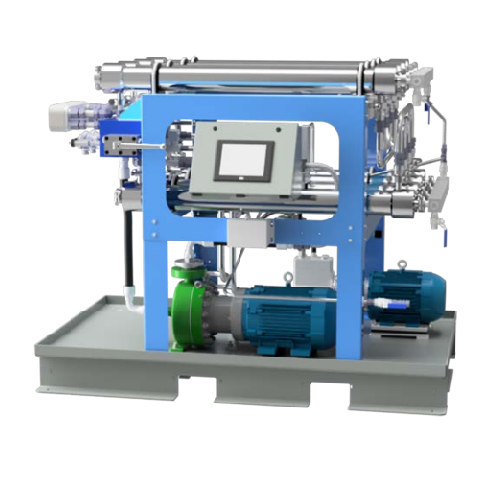

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

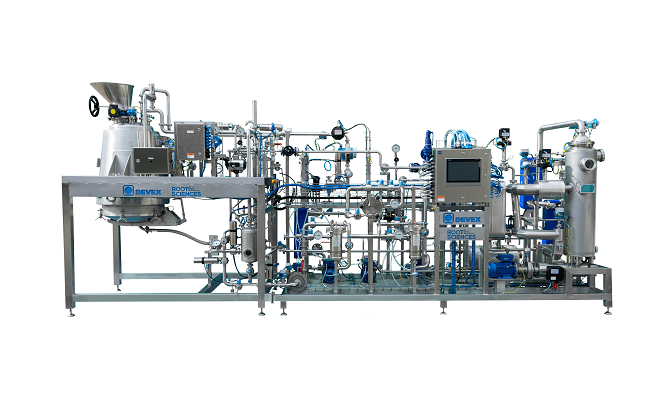

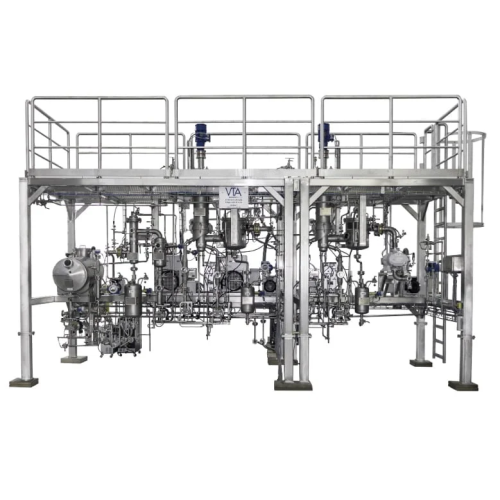

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Tell us about your production challenge

Where to extract it from? Hemp vs marijuana plants

Before getting the CDB oil for your production, there is some prior work you need to do. This includes cultivating and harvesting the cannabis plant, and then extracting the oil from it. You can extract CBD from two cannabis plants – hemp and marijuana. Hemp contains 0.3% or less of THC (tetrahydro cannabidiol), which is a psychoactive. The hemp plant also contains more CBD compared to the marijuana one. Marijuana, in its turn, has over 0.3% of THC.

While usually mistaken, CBD oil and hemp oil are different. You find and extract CBD oil from hemp flowers and leaves, while hemp comes from the crushing of hemp seeds.

CBD oil extraction equipment and steps

Farming is the first important thing to consider when making CBD oil. The plant soaks toxins from the soil, so it needs to grow organically in a controlled surrounding. You also need to harvest it before trichomes become milky white, which gives a moldy aspect to the plant. It’s important to use dryers right after harvesting.

Once you finish this, extraction can begin. It may occur by different methods, which involve CBD oil processing equipment in combination with hydrocarbon, ethanol, or CO2. These deliver crude cannabis oil, which you then need to purify.

Choosing the ideal CBD oil extraction method and equipment

Ethanol and CO2 are usually the safest solvents you can use in the CBD oil extraction process. In the ethanol process, you need to cool it down to -40 °C or even less to avoid solving undesired compounds with the oil. Then you must soak the plant in the ethanol to split the extract and the biomass. Next, ethanol evaporates in a different vessel, separating from the material. A “warm” ethanol process also works, but then requires winterization, which then removes the unwanted compounds that stayed during extraction. Cold ethanol increases process efficiency.

If you’re using CO2, you need to pressurize it, in a process that uses at least three chambers. One of them pressurizes and cools down the CO2; the second gets the plant material; the third captures CO2 back. CO2 may require winterization as some fats and waxes may stay in the oil, but is a healthy alternative that delivers a more aromatic extract. After extraction, you can start distillation.

Processing steps involved in CBD oil making

Which cbd oil technology do you need?

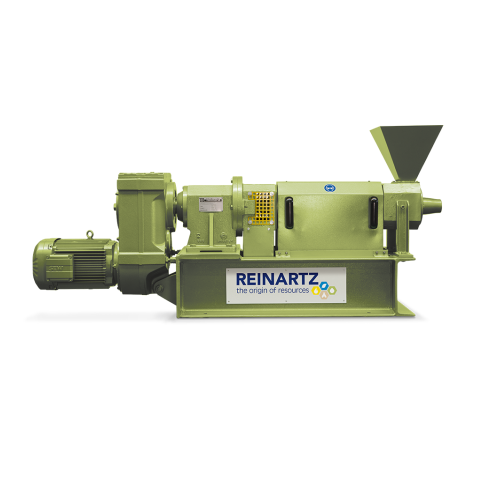

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

Vacuum cold trap for efficient purging and drying

Optimize your laboratory’s efficiency by integrating high-perform...

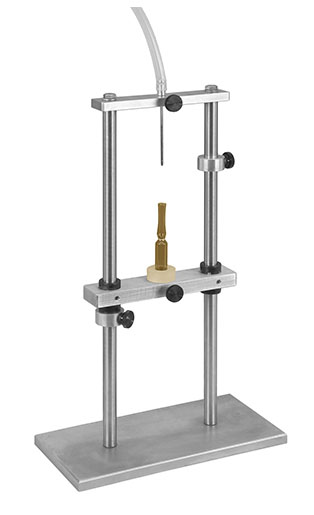

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Hydrocarbon solvent distillation unit for extractors

Ensure high purity levels in your extraction process by integrating ...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

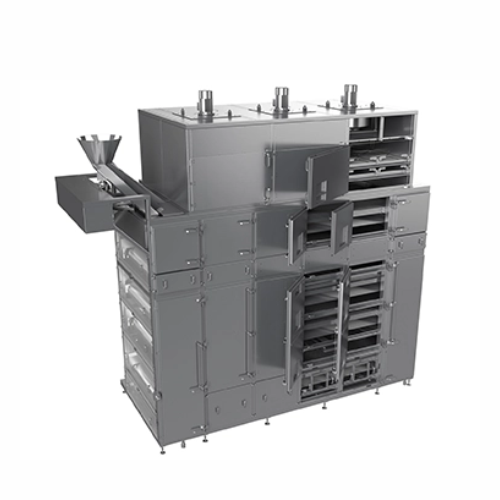

Batch-operated chamber dryer for surface drying

Enhance production efficiency with precise, low-temperature drying and coo...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

Continuous tunnel dryer for food products

Achieve precise moisture removal with adaptable drying technology, ensuring your...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

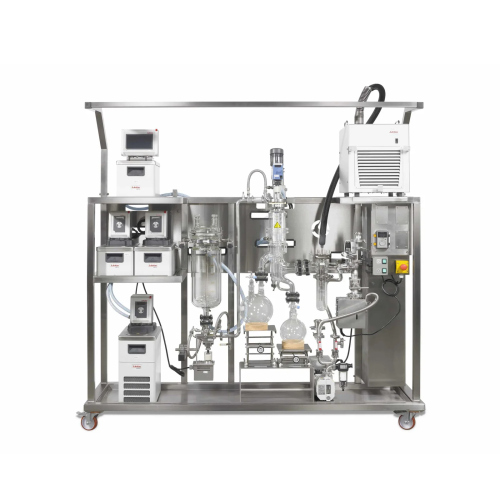

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

Solventless trichome separation for bubble hash production

Achieve high-quality, solventless extracts with superior tric...

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Inline chillers for ethanol extraction

Streamline your ethanol extraction process by quickly chilling alcohol to optimal te...

Supercritical Co2 fluid purification system

Optimize your extraction process with our supercritical CO2 fluid purification...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

Vertical seed conditioning system for oil extraction

Ensure optimal oil yield and quality from oilseeds by employing a ve...

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Industrial oil bleaching process

Optimize your oil purification process with advanced bleaching technology, significantly en...

Continuous deodorizing for oils and fats

Achieve optimal purity and flavor in oils and fats with advanced continuous deodor...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

Efficient desolventization and toasting solution for oilseeds

Optimize solvent removal and toasting in your oilseed proc...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

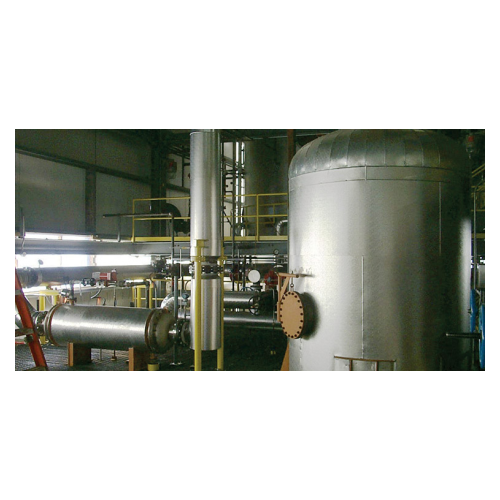

Mineral oil absorption system for solvent vapor recovery

Optimize solvent recovery and reduce atmospheric emissions with ...

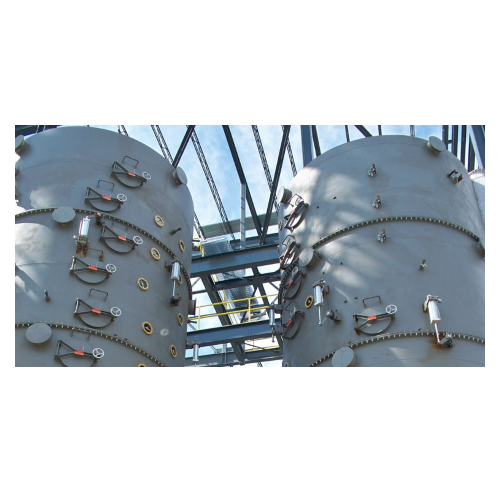

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

White flake desolventization for oilseed processing

Optimize your oilseed processing with a system designed to efficientl...

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Seed hull removal and condition system

Optimize your seed processing efficiency by effectively removing hulls and foreign m...

Biodiesel distillation process

Improve biodiesel quality by enhancing cold flow characteristics and removing impurities thro...

Biodiesel pretreatment system

Optimize your biofuel production by efficiently reducing impurities and unwanted components, e...

Dryer-cooler for solvent-extracted meal

Achieve optimal moisture and temperature control for solvent-extracted vegetable-oi...

Flash desolventization system for oilseed processing

Achieve rapid desolventization with minimal heat exposure, preservin...

Milling flash dryer for fine powder processing

Achieve precise moisture control and prevent agglomeration in your processi...

Soft gel encapsulation system

Efficiently produce high-quality soft gel capsules with precision encapsulation, rapid drying,...

Industrial roller compaction for chemical applications

Enhance material flow and density with advanced roller compaction ...

20l glass reactor for crystallization and isolation processes

Optimize your lab’s crystallization and isolation pr...

Decarboxylation package for botanical extraction

Ensure precise temperature control and efficient reaction conditions in y...

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

Dual-jacketed reactor for botanical extraction winterization

Optimize your production with precise temperature control a...

10l glass reactor system for synthetic reactions

Achieve consistent reaction control with efficient temperature and vacuum...

Large capacity jacketed glass reactor

Achieve precise control over temperature and vacuum conditions with this versatile re...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Tamper evident banding system

Ensure product integrity with a high-speed system designed to apply tamper-evident bands effic...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Solid-wall bowl separators for pharma extraction

Optimize your extraction processes with precision solid-wall bowl separat...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Capsule checkweighing system for pharmaceutical production

Ensure every capsule meets your precision weight standards wi...

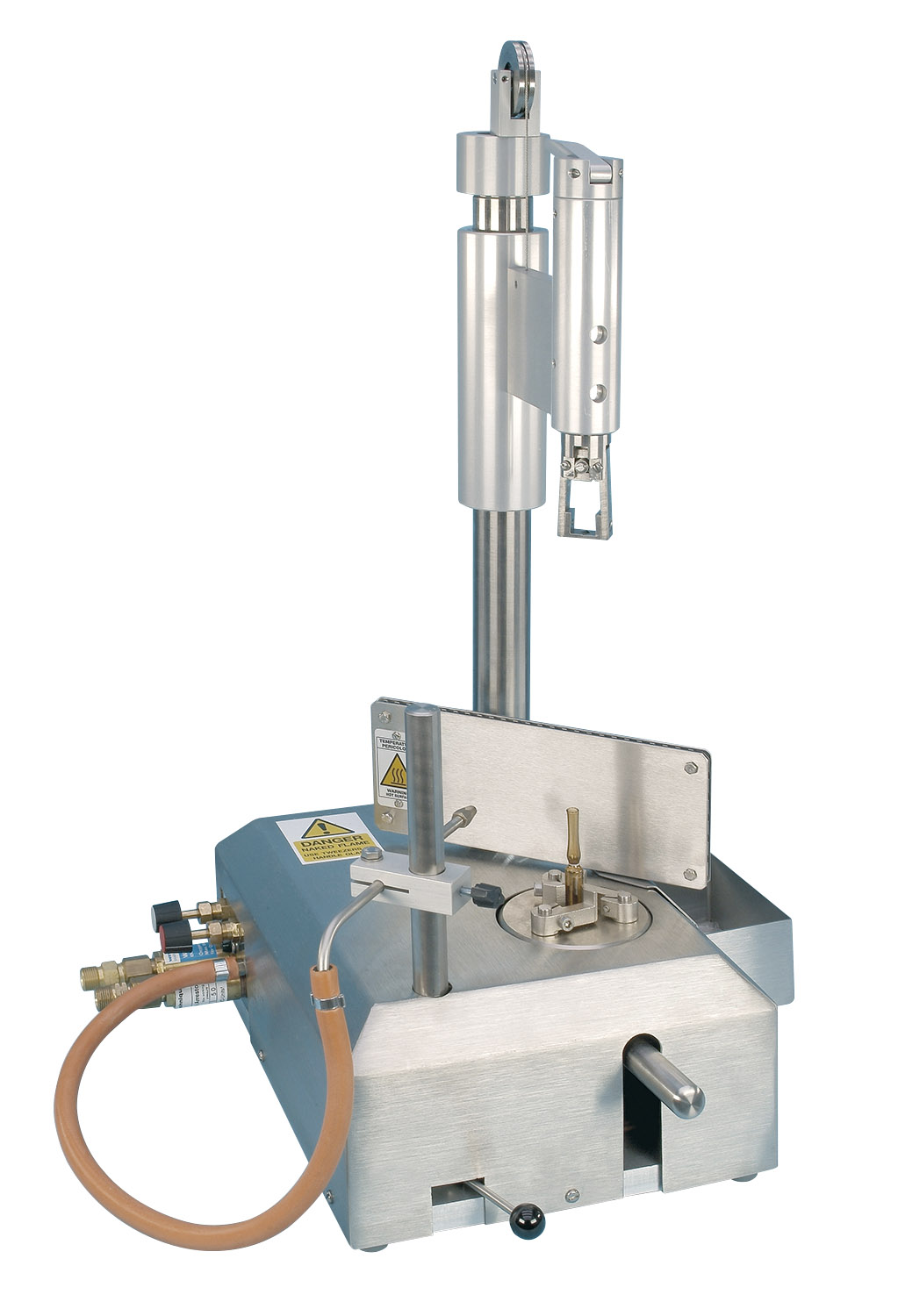

Cannabis and hemp short path distillation system

Achieve optimal cannabinoid purification with continuous high-volume dist...

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

Cannabis oil nanofiltration system

Achieve high-purity cannabinoid extracts with advanced nanofiltration, ensuring precise ...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Membrane nanofiltration for cannabis and hemp processing

Optimize your extraction processes with advanced nanofiltration,...

Cannabis nanoemulsification system

Transform your cannabis extracts into fast-acting, shelf-stable products with advanced n...

Solvent recovery and decarboxylation system

Enhance solvent recovery and streamline decarboxylation processes with an inno...

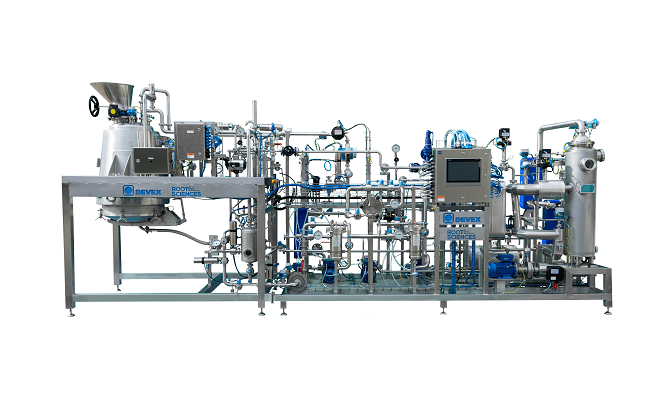

Industrial-scale cannabis distillation system

Achieve up to 99% cannabinoid purity effortlessly with an industry-standard ...

Short-path wiped-film distillation for cannabis

Achieve optimal cannabinoid purity with precise thermal separation, perfec...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Cannabis and hemp distillation system

Achieve up to 99% cannabinoid purity with high-throughput, continuous distillation th...

Cold processed ethanol extraction system

Streamline your extraction process by integrating an all-in-one system that combin...

Cannabis nanoemulsion equipment

Achieve clear, stable, and bioavailable cannabis nanoemulsions with high-pressure homogeniza...

Hydrocarbon extraction system for cannabis extraction

Achieve high-efficiency extraction with precise solvent control, op...

Hydrocarbon extraction system for cannabis and hemp

Streamline your extraction process with a versatile system capable of...

Hydrocarbon extraction equipment for cannabis and hemp processing

Optimize your extraction processes with a high-capaci...

Hydrocarbon extraction system for cannabis

Optimize your cannabis concentrate production with a flexible hydrocarbon extra...

Laboratory homogenizer for cannabis nanoemulsion production

Achieve exceptional bioavailability and stability with high-...

Cannabis nanoemulsification system for high-precision production

Achieve rapid bioavailability and stable formulations i...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

Manual ampoule filler

When you fill ampoules it is essential to avoid wetting the inside walls of the container, as it may af...

Benchtop ampoule opening and closing equipment

The procedure for opening or closing ampoules requires you to handle gas an...

Automatic centrifuge for cannabis

Centrifugation is an effective method for producing cannabis extracts. The extraction pro...

Fully certified CBD crude oil extraction machine

Traditional extraction processes involving hot solvent (ethanol) or Co2 m...

Benchtop cannabis filter press

Therapeutic uses for cannabis oil are becoming more widely available. For pharmaceutical uses...