Industrial roller compaction for chemical applications

Enhance material flow and density with advanced roller compaction technology, ideal for transforming bulk powders into uniform granules, ensuring efficient processing and reduced waste in your production line.

Compacts and Granulates Bulk Materials Efficiently

The PP Series from Alexanderwerk is engineered for optimized compaction and granulation of diverse bulk materials, tailored for chemical, pharmaceutical, and industrial applications. By utilizing a vertical roller orientation and vacuum de-aeration, this equipment effectively manages material densification and particle size distribution. It’s suitable for applications ranging from pigment powders and 3D printed components to battery electrodes and protein supplements. With processing capacities reaching up to 25,000 kg/h, depending on the model, the PP Series facilitates high throughput in continuous operations. Its robust construction features double-sided bearing rollers, allowing for high press forces up to 96 kN/cm, making it efficient for dense material compaction. The integrated control system ensures seamless automation, enhancing operational consistency and efficiency. Available in stainless steel, the PP Series is constructed for durability and material compatibility, vital for handling corrosive substances typical in fine chemicals production. Designed with hygiene in mind, this equipment supports easy maintenance with components accessible for cleaning and CIP options. Customizable features, supported by Alexanderwerk’s engineering expertise, allow for precise tailoring to meet specific processing needs.

Benefits

- Enhances production efficiency by processing up to 25,000 kg/h.

- Minimizes dust and fines, ensuring safer handling of explosive powders.

- Achieves consistent granule quality, improving downstream processing reliability.

- Reduces operational costs through high-speed, continuous operation.

- Offers robust material compatibility, ideal for harsh chemical conditions.

- Applications

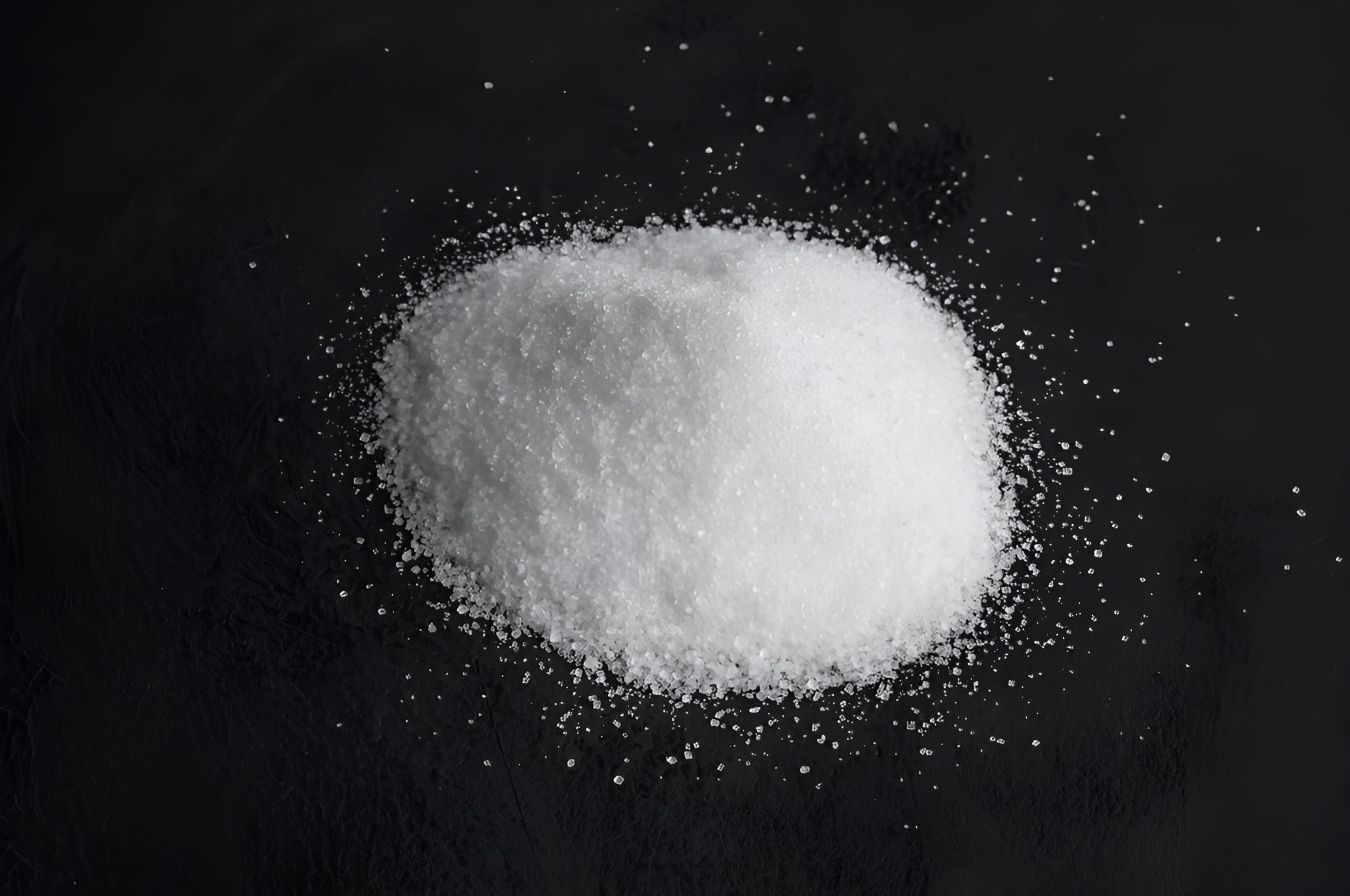

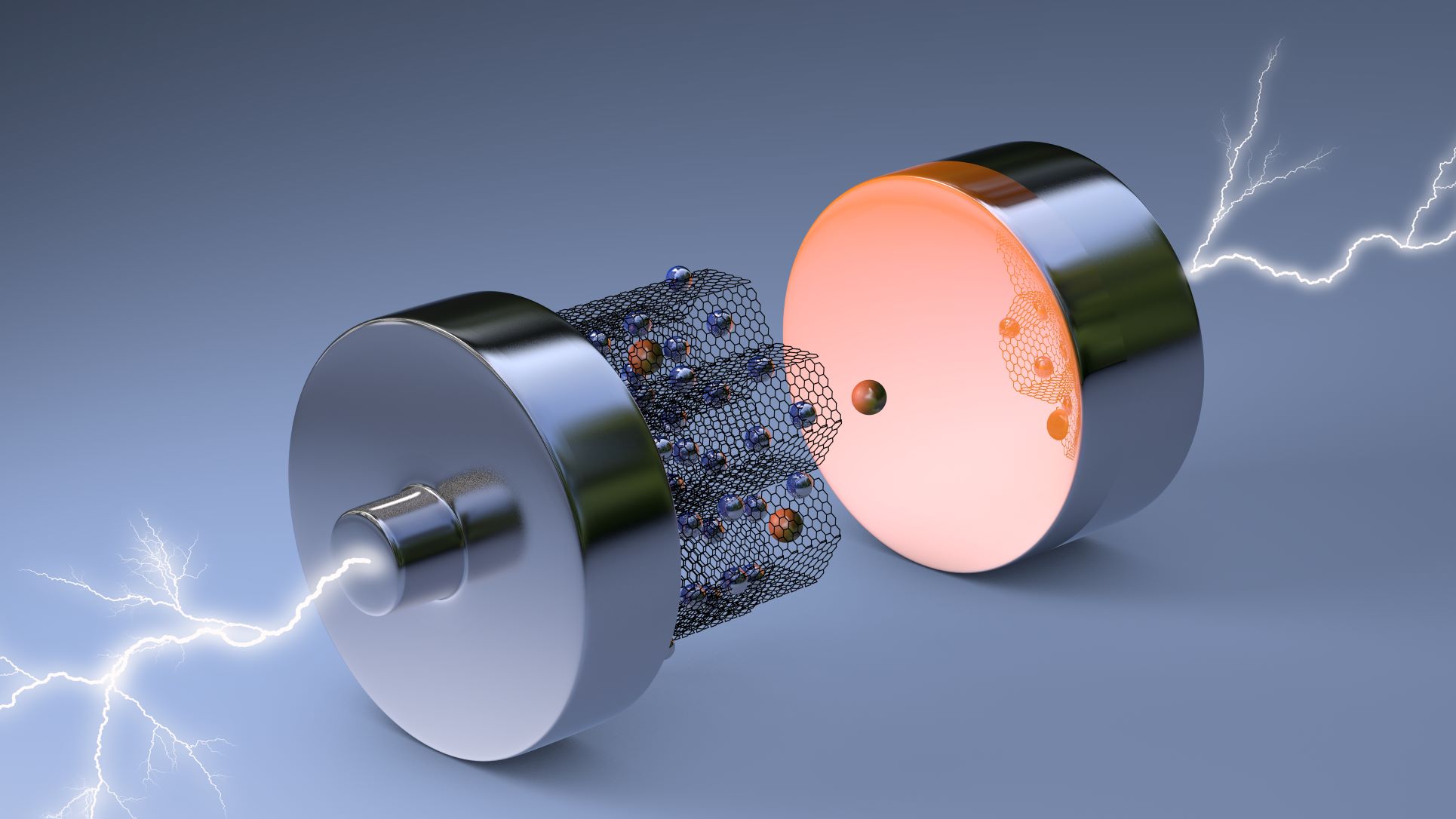

- Metal powders, Polycarbonate, Fine chemicals, Silica, Biological bulk materials, Toner, Cbd crystals, Fertilizers, Airbag powders, Sodium carbonate, Battery mass, 3d printing powders, Salts

- End products

- 3d printed components, Polycarbonate sheets, Metal additive components, Table salt, Airbag inflation modules, Potash fertilizer, Cbd capsules, Battery electrodes, Printer toner cartridges, Protein supplements, Pigment powders, Fumed silica gel, Ph regulators

- Steps before

- Purification, Drying, Blending, Grinding, Powder Preparation

- Steps after

- Granulation, Particle Size Distribution Adjustment, Packaging

- Input ingredients

- powder, bulk materials, fine chemicals, chemical blends, natural bulk materials, biological bulk materials, THCA crystals, CBD isolate, 3D printing powders, polycarbonate, sodium carbonate, metal powders, battery mass, salts, fertilizers, silica, fumed silica, airbag powders

- Output ingredients

- compacted flakes, granules, increased bulk density materials, improved flow characteristics materials

- Market info

- Alexanderwerk is renowned for manufacturing specialized machinery and equipment for the pharmaceutical, chemical, and food industries, particularly known for their high-quality roller compaction and granulation technologies, which enhance production efficiency and product quality.

- Roller Diameter

- 150 mm, 175 mm, 250 mm, 350 mm, 500 mm

- Roller Width

- 75/150/300 mm, 90/180/360 mm, 125/250/500 mm, 165/350/700 mm, 250/500/1000 mm

- Throughput,Continuous Operation

- up to 400 kg/h, up to 1000 kg/h, up to 5000 kg/h, up to 15000 kg/h, up to 25000 kg/h

- Maximum Press. Force

- 30 kN/cm, 48 kN/cm, 60 kN/cm, 96 kN/cm

- Maximum Roller Gap

- 5 mm, 6 mm, 8 mm, 10 mm

- Maximum Roller Speed

- 30 rpm

- Automation

- PLC-controlled

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies by model (e.g., PP 150 C

- Roller Diameter

- 150 mm to 500 mm

- Roller Width

- 75/150/300 mm to 250/500/1000 mm (varies by model)

- Maximum Roller Gap

- 5 to 10 mm

- Roller Speed

- 30 rpm

- Compact footprint

- Integrated control systems within the machine

- Discharge method

- Granulation with bar rotor

- Control panel type

- Integrated with process control components

- Weight

- 1, 500 kg to 15, 000 kg (varies by model)

- Control panel type

- Integrated Control System

- HMI (Human-Machine Interface)

- Touchscreen Interface

- Integration possibilities

- SCADA Integration

- Compact footprint

- Yes

- Discharge method

- Automatic Granule Discharge