Short-path wiped-film distillation for cannabis

Achieve optimal cannabinoid purity with precise thermal separation, perfect for continuous processing where maintaining high-potency distillate quality is essential.

Purifies and Distills Cannabis and Hemp Oils

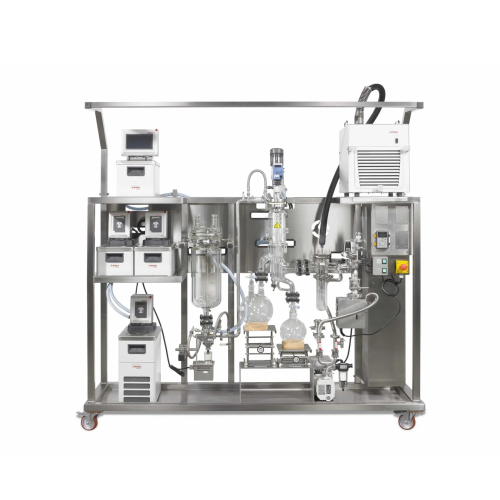

The VKL 70-S from Root Sciences is engineered to deliver high-purity cannabis and hemp distillates through short-path wiped-film distillation. This system excels in the continuous processing of cannabinoid and essential oil purification, offering a fully jacketed design that maintains product flow without the need for additional heating elements. With a capacity of up to 3.5 L/h, it ensures precise control via a German-engineered gear pump, making it ideal for GMP-compliant operations. The transparent glass construction allows operators to monitor conditions within the evaporator, facilitating optimal processing control. Built to UL standards with durable 316 stainless steel and borosilicate glass, the VKL 70-S is equipped for easy cleaning and maintenance, and can be customized with components such as liquid and immersion chillers. This system integrates smoothly into production lines, supporting both pilot and full-scale operations in cannabis, hemp, pharmaceutical, and chemical industries.

Benefits

- Maximizes yield with precise feed rate control, enhancing product consistency.

- Achieves up to 99% cannabinoids, delivering high-potency distillates.

- Continuous operation reduces processing time and increases throughput.

- Transparent system design aids in real-time monitoring and control, minimizing operational errors.

- Customizable to meet GMP requirements, ensuring compliance with global standards.

- Applications

- Cannabis, Hemp, Cannabinoids, Essential oils

- End products

- Full-spectrum cannabinoid distillate, Cannabis oil, Cannabis distillate, Hemp distillate, Cbd distillate, Thc distillate, Hemp oil

- Steps before

- Crude oil extraction, Filtration, Winterization, Decarboxylation

- Steps after

- Cannabinoid testing, Potency verification, Product formulation, Packaging

- Input ingredients

- cannabis crude oil, hemp crude oil

- Output ingredients

- cannabis distillate, hemp distillate, up to 99% total cannabinoids

- Market info

- Root Sciences is known for providing high-quality extraction, distillation, and other processing equipment for the cannabis and hemp industries, offering solutions for creating purified concentrates and extracts, emphasizing efficiency and innovation.

- Feed rate

- 1.3 L/h (Typical), 3.5 L/h (Maximum)

- Evaporator Surface Area

- 0.05 m²

- Power Requirements

- 1Φ 230 V, 60 Hz

- Stages

- Single

- Dimensions

- 6.6’ x 2.3’ x 6.6’

- Materials Used

- 316 stainless steel, borosilicate glass, PTFE glass fiber reinforced rollers

- Throughput Capability

- 1.3 L/h (Typical), 3.5 L/h (Maximum)

- Automation

- German engineered gear pump

- Visibility

- Transparent glass system

- Working Mechanism

- Wiped-Film Short Path Distillation

- Automation Level

- Manual / PLC

- Heating Method

- Fully Jacketed System

- Feed Rate Control

- Regulated by German engineered gear pump

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Manual

- Visible Processing Control

- Transparent Glass System

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- UL certification

- UL ready (all necessary individual components are UL listed)

- Machine Footprint

- 6.6’ x 2.3’ x 6.6’

- Evaporator Surface Area

- 0.05 m²

- Materials Used

- 316 stainless steel, borosilicate glass, PTFE glass fiber reinforced rollers

- Feed Method

- German engineered gear pump

- Discharge Method

- Separate heater for residue discharge arm (option)

- Control panel type

- PLC-controlled

- Customization for GMP Compliance

- According to URS

- Feed Vessel Capacity

- 5 L

- Heating Customization

- Fully Jacketed System

- Cold Trap Customization

- Liquid Chiller / Immersion Chiller

- Residue Discharge Heating

- Separate Heater

- IQ,OQ,FAT,SAT

- Available as GMP Package