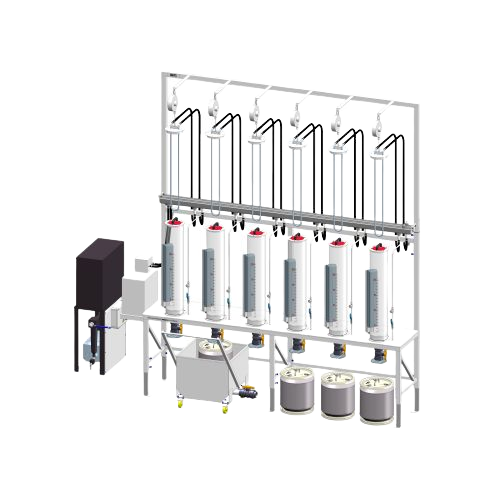

Seed priming equipment

Seed priming is a controlled hydration technique in which seeds are soaked in water or low osmotic potential solution to a point where germination related metabolic activities begin in the seeds but radical emergence does not occur. It is essential that all seeds come into good contact with the liquid in the priming tubes. It is also important that the temperature of the liquid can be set and controlled. In some cases, lighting is also applied to the priming tubes.

Achieve a more uniform and faster germination

The seed osmotic priming unit by Seed Processing Holland is used to enhance seeds in an osmotic-altered solution. Primed seeds usually germinate more quickly than untreated ones, resulting in higher quality crops.

The unit’s six priming tubes are designed with two-hand grips, making it easier for operators to remove them. A compressed air control valve is attached beneath each priming tube, which can be used to control the air quantity in each priming tube.

Furthermore, a heating and cooling system can be mounted above each tube, enabling users to heat or cool the solution. Also lighting can be added as an option by each priming tube. Although the priming unit boasts a fixed set up, it can be attached with wheels to make it more mobile.

Moreover, the priming tubes are clear, so you can see the treatment process. Lastly each tube boasts a maximum capacity of eight litres.

Benefits

- Priming tubes made from cast acrylate to ensure a good view at the process

- Stainless steel frame ensures that the unit will last for years to come

- Quick action couplings enable operators to easily empty the tube