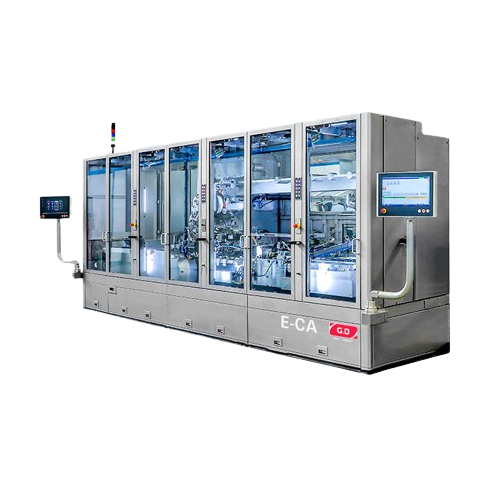

Cartridge assembler for next generation vapour products

Optimize your production of vape cartridges and e-cigarette pods with this high-speed assembly solution, designed for seamless integration into your processing and packaging lines, ensuring precision and efficiency at every step.

Assembles and Fills Vape and Hemp Cartridges

The E-CA Cartridge Assembler from G.D S.p.A is engineered for high-speed, continuous assembly and filling of vape cartridges and e-cigarette pods. This equipment excels in integrating multiple processes such as assembly, combining, and filling, optimizing efficiency for tobacco and hemp product producers. Capable of processing both solid and liquid components, it ensures accurate production of vape cartridges, including tobacco-infused and CBD variants. With PLC-controlled automation, it seamlessly integrates into existing production lines, enabling remote monitoring and smooth operation. Designed for endurance, it caters to high throughput demands while maintaining energy efficiency. Customization options and comprehensive engineering support are available to tailor machine specifications to your exact requirements.

Benefits

- Enhances production efficiency with high-speed, continuous operation.

- Reduces labor costs through fully automated PLC-controlled processes.

- Accommodates diverse product lines, including tobacco and CBD cartridges.

- Ensures precision filling, minimizing material waste.

- Offers seamless integration with existing production lines for streamlined workflow.

- Applications

- Tobacco, Vapour, Hemp-based products

- End products

- Hemp vape cartridges, Cbd vape cartridges, E-cigarette pods, Vape cartridges, Tobacco-infused vape cartridges

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Packing, Coating, Filling

- Input ingredients

- tobacco, vapor ingredients, cartridge components, hemp products

- Output ingredients

- assembled cartridge, vaping cartridges, next generation vaping products

- Market info

- G.D (Coesia Group) is renowned for designing and manufacturing high-precision automatic machines, with expertise in tobacco processing and packaging solutions, reflecting a strong reputation for quality and innovation in industrial machinery.

- Speed

- 300 cpm (cartridges per minute)

- Automation

- Automated Cartridge Assembly

- Industrial Application

- Next Generation Tobacco Products

- Product Compatibility

- Vapour and Hemp-based products

- Working mechanism

- Cartridge assembly

- Integrated steps

- Assembly, combining

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Energy efficiency

- Optimized for high throughput

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Cartridges

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Modular automation system

- Hemp product compatibility

- Yes

- Capacity options

- Up to 300 cpm