Find CBD Gummy equipment

Find innovative production technology for making cbd gummies and connect directly with world-leading specialists

Gummies make everything more colorful. The squishy droplets make a tasty and practical carrier of special ingredients such as CBD oil. Chewing the gum increases the bioavailability of the substance as opposed to vaping. But before the cannabidiol can take effect, it must first be processed through a line of CBD gummy equipment.

Technology picks for CBD gummies

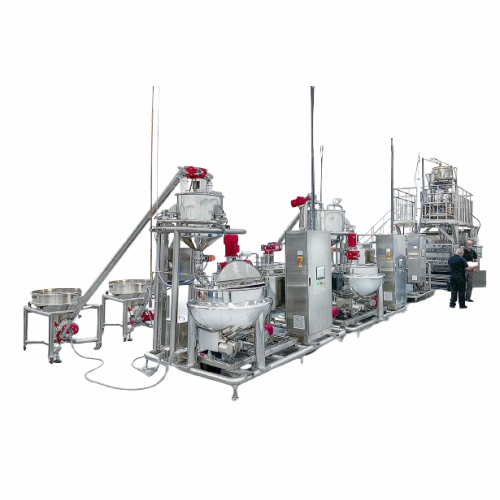

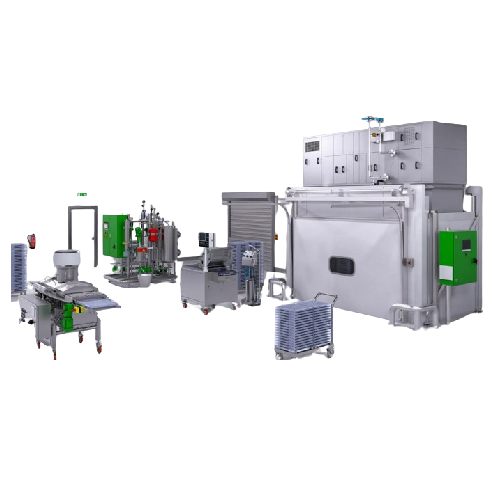

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

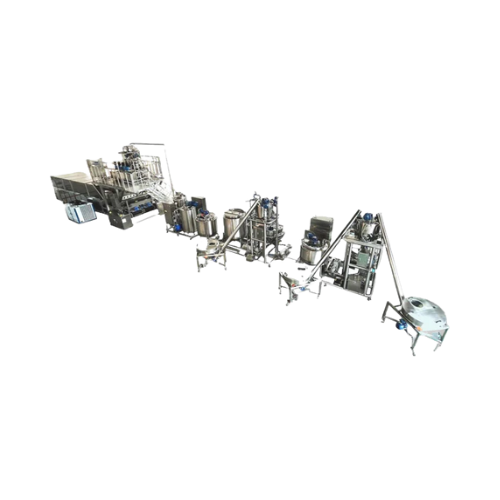

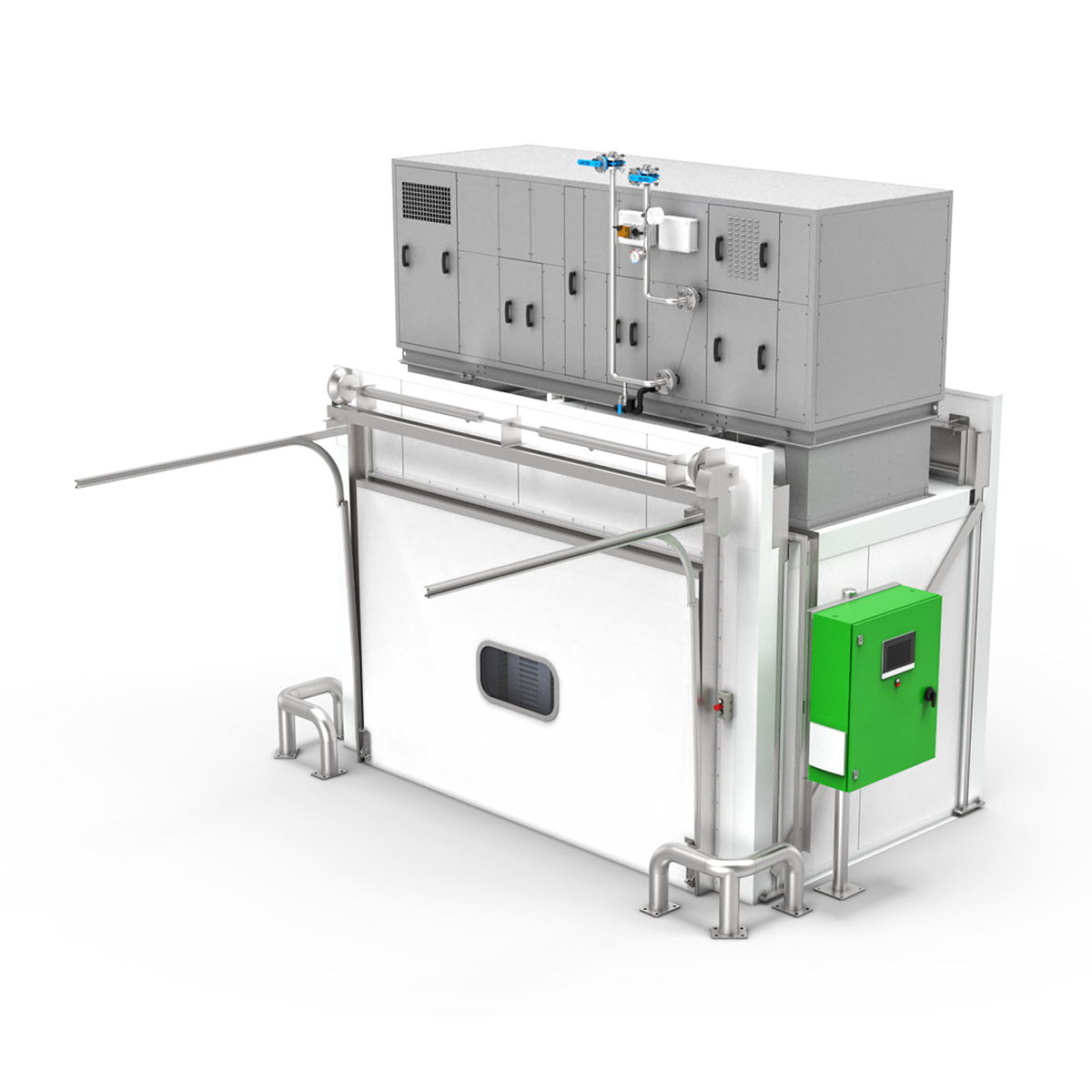

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Stories about cbd gummies

Starting up your OTC non-starch gummy production

How to turn a bag of sugar into a bag of scrumptious gummies

There’s way more to see with CBD

Get sweet with weed in the endeavor of crafting cannabis candy

Preserving gummy texture in low or no sugar confectionery

How to craft gummy bears in 8 simple steps

Exploring the artistry of candy-making

Two steps to stop formula deviation in CBD Gummies

Tell us about your production challenge

Advanced CBD gummies equipment eliminates the need for starch

The earliest gummy candy manufacturing processes lined the mold trays with starch to prevent the gelatinous mix from sticking. But applying and removing starch slows production. New automated processing technologies bypass this technique by using non-stick GMP materials.

Starch-free depositing trays present other opportunities too. Molds have an improved definition with smoother, refined edges. Starch-lined pans are often limited to flat and two-dimensional molds. But non-stick technology allows you to manufacture your gummies in true 3D. Advances in gummy production technology mean that a consistent and high quality end-product is produced. PLC (Programmable Logic Controllers) help with production capacity in terms of input and output no matter what recipe you decide to go with.

Setting up your entry-level gummy factory

When producing CBD or mushroom gummies on a small scale you must consider whether you prefer your equipment to be fully or semi-automated. While producing in smaller capacities compared to large scale gummy makers, your gummy manufacturing technology allows for more efficient production runs tailored to your specific needs.

You are more agile and adaptable compared to big producers, allowing you to innovate and respond quickly to market changes. Therefore the gummy formulation process is less complicated for you and you can modify gummy production schedules and quantities more easily to meet fluctuating demand or variations.

Replace gelatin with pectin to improve the setting time

The chewy texture of gummies is all thanks to gelatin. The animal-derived substance forms into a flexible matrix that holds together the other ingredients in the mix.

However, one drawback of gelatin is that it may take up to four hours to set. A naturally occurring fiber found predominantly in fruits, Pectin is a suitable replacement. Although it does not achieve the same bouncy consistency as gelatin, it takes minutes to set.

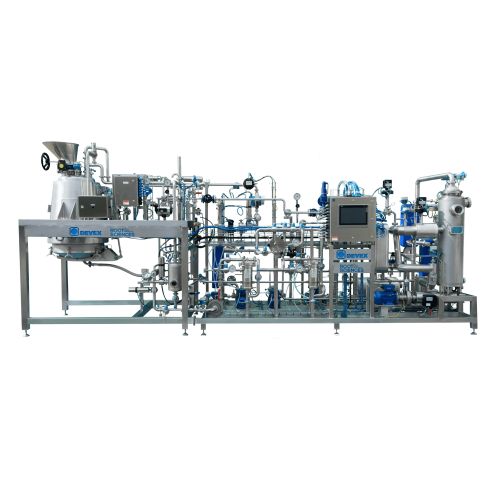

Extract CBD oil from hemp using cryogenic ethanol

Cannabidiol (CBD) is one of the chemicals developed by the cannabis Sativa plant. THC, which acts as a stimulant or hallucinogen when consumed, is another chemical in this mix. But CBD is extracted from the hemp flower, which has a low THC concentration of 0.3% or less.

CBD oil is obtained from industrial hemp using solvent extraction. The plant material is immersed in a solvent such as cryogenic ethanol and brought to a temperature of about -40°C. The ethanol breaks down the tissue, releasing the compounds. Isolate the CBD oils from unwanted residues using a separation technique like chromatography. Humidity is something important to keep in mind throughout the whole process.

Tailor your CBD product to the country-specific legal framework

The United States and Europe are the two largest markets for CBD products. The US federal authorities (2018 Farm Bill) allow the use of ingredients derived from hemp. Nevertheless, CBD products are not expressly legal. States within the country have taken it upon themselves to regulate the sale of CBD gummies.

On the other side of the Atlantic, European law does not consider CBD a narcotic drug, but marketing CBD derivatives is a national competence. Not all EU member states allow sales of CBD products, while the rest have varying tolerance for THC levels.

Processing steps involved in CBD gummies making

Which cbd gummies technology do you need?

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Cooker for jelly and gummies production

Experience efficient gummy and jelly production with precise heating and mixing, en...

Automatic gummy production system

Achieve precise control in gummy production with systems that cater to diverse formulatio...

Powder and oil coating system for gummies

Enhance your gummy production with precise powder and oil coating, achieving con...

Oil coater for gummies

Optimize your gummy production with high-speed oil coating for consistent, flavorful finishes, ensurin...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Sugar coating system for gummies

Achieve a flawless sugar coat on up to 240,000 gummies per hour, seamlessly integrating int...

Portable water activity meter for gummy production

Ensure consistent gummy quality and extended shelf life by precisely m...

High-capacity gummy production system

Optimize your gummy production with a starchless system that deposits up to 240,000 g...

Automatic gummy production system for Cbd and vitamin gummies

Achieve high-speed, continuous gummy production with preci...

High-capacity automatic gummy production line

Achieve high-speed gummy production with precision depositing and cooling, i...

Automatic gummy candy production system

Maximize your confectionery output with a high-speed system capable of producing up...

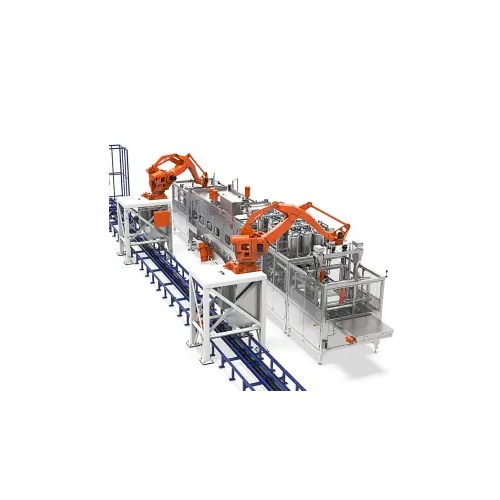

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

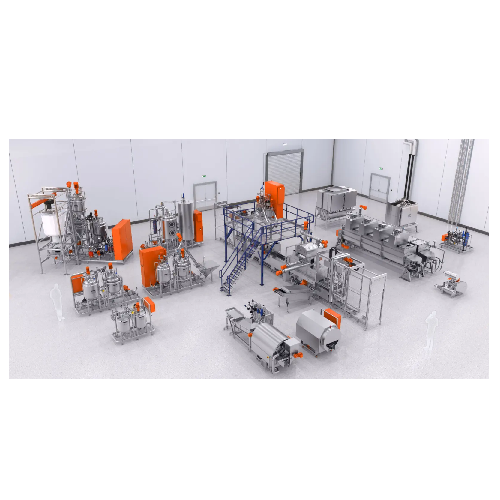

Industrial gummy and jelly production line

Optimize your gummy and jelly production with a system that streamlines operati...

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

Entry-level gummy and jelly production line

Looking to produce gummies and jellies with functional ingredients? This produ...

Automatic production line for gummies, jellies, and nutraceuticals

Optimize your production space with a compact line t...

Robotic production line for gummies and nutraceuticals

Streamline your gummy and nutraceutical production with a versatil...

Robotic high capacity production line for gummies and jellies

Optimize your gummy and jelly production with a high-capac...

High capacity cannabis cryo-ethanol extraction line

Boost extraction efficiency with high-capacity cryo-ethanol technolog...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Automatic centrifuge for cannabis

Centrifugation is an effective method for producing cannabis extracts. The extraction pro...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...