High-shear processors for uniform nanoparticles

Optimize particle size reduction and achieve uniformity in nanoparticle formulations across pharmaceuticals and food with precise high-shear processing.

Processes and Homogenizes Nanoparticles and Liquids

Dyhydromatics’ ShearJet line, including the HL60 V2, PL300, and HP1200 V2 models, delivers precise high-shear processing capabilities catering to pharmaceuticals, biotechnology, and food industries. The ShearJet HL60 V2, with its electric hydraulic drive, is designed for R&D labs, processing volumes from 3 mL to 500 mL at pressures of up to 30,000 psi. The ShearJet PL300 suits medium volume applications, offering pneumatic operation with up to 23,000 psi pressure for pharma and non-pharma uses.

For pilot-scale operations, the HP1200 V2 model provides continuous processing with customizable pressure modules, handling volumes from 250 mL to 150 liters. All models integrate seamlessly into existing production lines, supporting upstream and downstream processes with options for semi-automatic or fully automated control via HMI interfaces. They are engineered to optimize energy consumption and feature material options for corrosive environments, ensuring compliance with relevant industry standards and certifications.

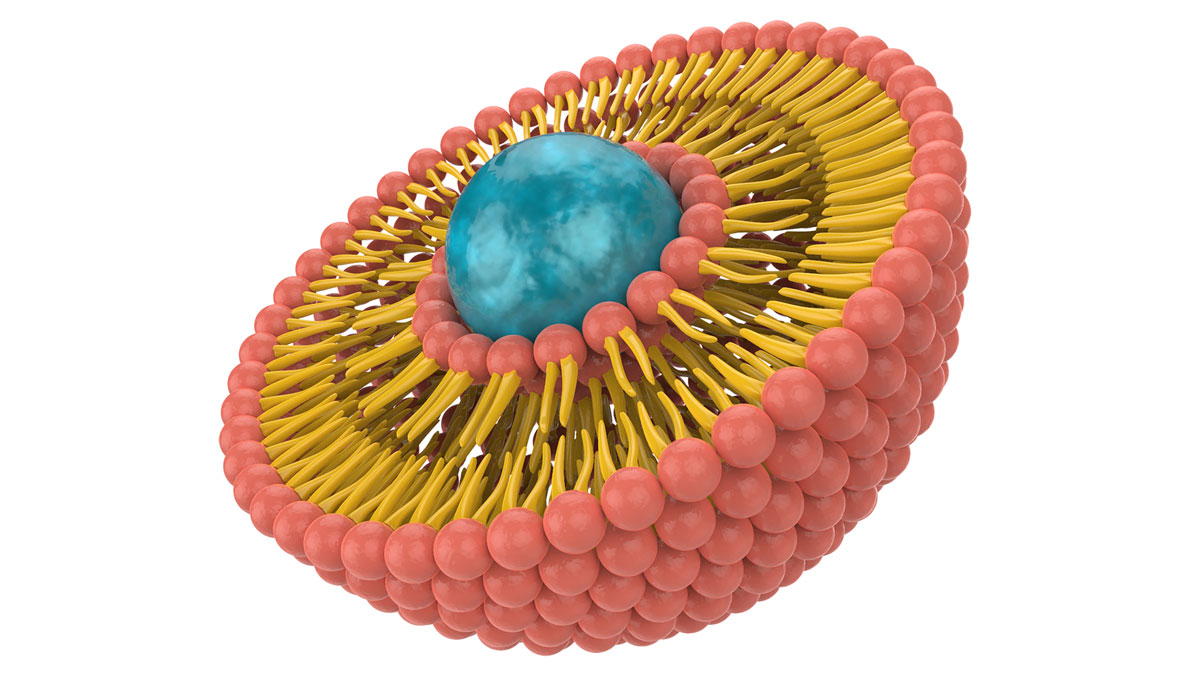

These processors efficiently reduce particle sizes and homogenize various products, including nanoparticle drug formulations and emulsified compounds. They incorporate advanced cooling through innovative heat exchanger designs, maintaining product integrity while ensuring operational reliability. Dyhydromatics supports customization with engineering services to tailor equipment to specific production needs, extending machine life and reducing maintenance costs.

Benefits

- Enhances product quality with uniform particle size distribution, ensuring consistent end-product performance.

- Reduces operational costs by maintaining continuous processing with minimal manual intervention.

- Optimizes energy use through precise motor control, lowering energy consumption and operational expenses.

- Ensures regulatory compliance with available GMP and FDA standards, particularly for pharmaceutical applications.

- Prolongs equipment lifespan with robust design and material options suitable for corrosive and demanding environments.

- Applications

- Chemicals, Personal care, Food, Biotechnology, Cannabis, Pharmaceuticals

- End products

- Nanoparticle drug formulations, Emulsified chemical compounds, Liposomal formulations, Personal care creams and lotions, Cannabis-infused oils and extracts, Protein suspensions, Nutraceutical liquids, Homogenized food ingredients

- Steps before

- Premixing, Flow monitoring, Product tank preparation

- Steps after

- Downstream processing, Packaging, Product outlet temperature control

- Input ingredients

- particle size, sample size, liquid samples, feed materials

- Output ingredients

- uniform particle size distributions, nanoparticles, processed products

- Market info

- Pressure Range

- 5, 000 to 30, 000 psi

- Volume Capacity

- 3 mL to 500 mL and beyond

- Flow Rate

- 68 mL/min (Small Volume), 300 to 450 mL/min (Medium Volume), 1L – 3.5L/min (Pilot Scale)

- Stroke Volume

- 1 mL (Small Volume), 6 mL (Medium Volume)

- Cooling System

- Chiller with heat exchanger

- Operation Mode

- Continuous Operation at Maximum Pressure

- Data Acquisition

- Available

- User Interface

- HMI with Multi-level User Interface

- Cleanroom Compatibility

- Pharma and non-pharma versions

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Small footprint

- Noise level

- 70 db

- Operation type

- Electric hydraulic driven / Pneumatic driven

- Cooling method

- Product heat exchanger with chiller

- Mobility

- Casters for mobility between suites

- Process controller

- Integrated HMI

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Manual, semi-automatic, fully automated

- Additional features

- Quick disconnect cooling water connections

- Product path customization

- Electropolished and passivated