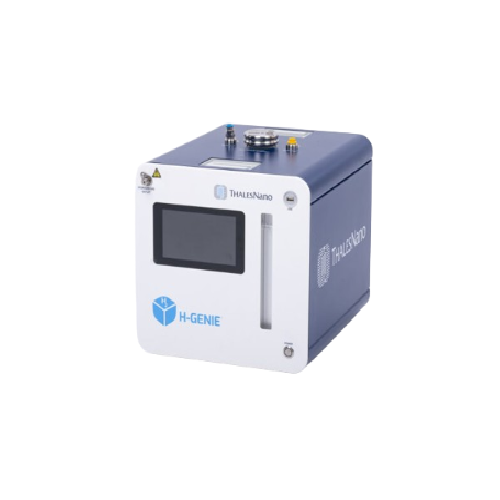

On-demand hydrogen generation system for laboratory use

Eliminate the risks and inconveniences of traditional hydrogen cylinders with a compact solution that generates high-purity hydrogen on-demand, directly from water, expanding your laboratory’s chemistry capabilities safely and efficiently.

Generates On-Demand High-Purity Hydrogen for Laboratory Use

The H-Genie® from ThalesNano is a compact and innovative solution designed for laboratory environments requiring on-demand hydrogen generation. This system stands out by eliminating the need for traditional gas cylinders, producing hydrogen directly from deionized water at high purity levels of 4.0 grade. It operates at pressures up to 100 bar, supporting diverse applications in fine chemicals, pharmaceuticals, and petrochemicals. With a flow rate adjustable up to 1 NL/min, it’s particularly effective for processes such as hydrogenation and catalyst screening. The unit’s versatility is enhanced by its compatibility with various reactors and its integration into both benchtop and automated setups. Designed with safety in mind, the H-Genie® includes an internal hydrogen detector and data monitoring capabilities, providing real-time system status through convenient data export. Its compact design minimizes the laboratory footprint, while its robust engineering ensures reliable performance under demanding conditions, compliant with stringent laboratory safety standards.

Benefits

- Enhances laboratory safety by eliminating the need for high-pressure gas cylinders.

- Increases operational flexibility with on-demand hydrogen generation.

- Supports a wide range of chemical reactions, optimizing experimental throughput.

- Saves space with a compact and user-friendly design.

- Provides real-time monitoring and data export for improved process control.

- Applications

- Catalysts, Petrochemicals, Fine chemicals, Pharmaceuticals

- End products

- Polyethylene, Ethylene glycol, Platinum catalysts, Olefins, Ibuprofen

- Steps before

- Water purification, Reactor setup, Catalyst preparation

- Steps after

- Chemical reaction monitoring, Data analysis, Reaction sample testing

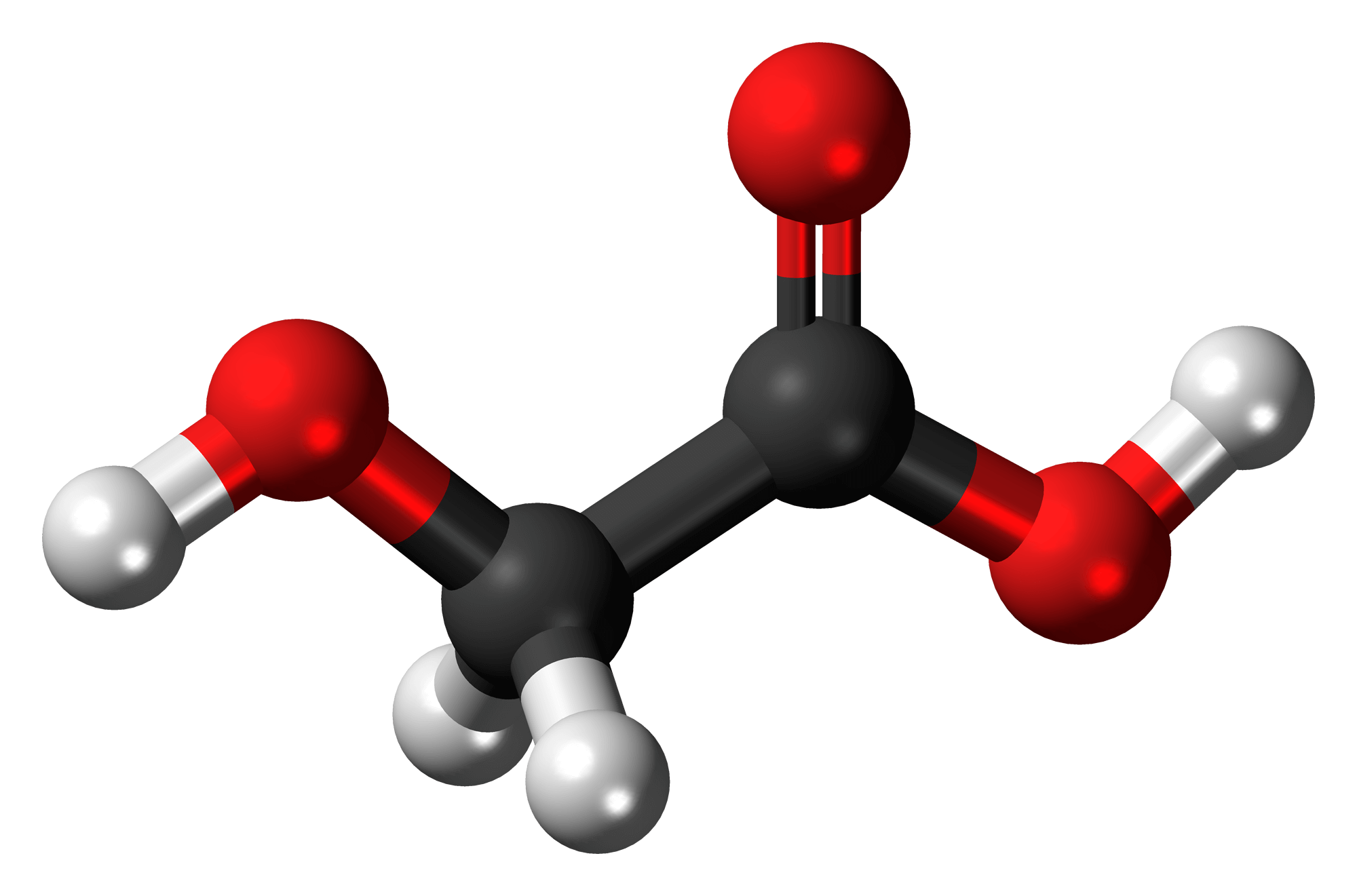

- Input ingredients

- deionized water, heavy water, MilliQ water, MilliPure water

- Output ingredients

- 4.0 purity hydrogen gas, 99.99% purity hydrogen

- Market info

- Thalesnano is known for manufacturing advanced flow chemistry solutions, particularly in catalyst and hydrogenation technologies. They are recognized for their expertise in continuous processes, enhancing safety and efficiency in chemical synthesis.

- Hydrogen Production Rate

- 0.1-1 NL/min

- Output Pressure Range

- 1-100 bar

- Purity

- ≥ 99.99% (4.0 @ 100 bar)

- Water Consumption Rate

- 250 mL/hr

- Water Reservoir Capacity

- 3L

- Unit Dimensions (H x W x D)

- 345 mm × 365 mm × 460 mm

- Unit Weight

- 38 kg

- Outlet Parameter

- Swagelok O.D.

- Working Mechanism

- On-demand hydrogen generation from water

- Flow Rate Control

- Variable flow rate

- Pressure Control

- 1-100 bar

- Safety Features

- Internal hydrogen detector

- Compatibility

- Compatible with any reactors and balloons

- Operation Environment

- Ventilated laboratory fume hood

- Data Monitoring

- Monitors hydrogen consumption with export functionality

- Automation Level

- Integrated data monitoring and control

- Water Source

- Deionized water

- Temperature Range

- Up to 450°C with compatible systems

- Compatibility with High Pressure

- Up to 100 bar

- Compatibility with High Temperature

- Up to 450 °C

- Compatibility with Swagelok fittings

- 1/8" O.D.

- Machine footprint

- 345 mm × 365 mm × 460 mm

- Weight

- 38 kg

- Discharge method

- Swagelok O.D.

- Water reservoir capacity

- 3L

- Control panel type

- Internal hydrogen detector

- Control panel type

- Integrated

- Integration possibilities

- Compatible with any reactors and balloons