Chromatography process for high-purity industrial separation

Achieve continuous high-purity separation and purification of complex mixtures with advanced chromatography technology, ideal for operators seeking efficient, sustainable processes that minimize chemical usage and energy consumption.

Continuously Separates and Purifies Complex Liquid Mixtures

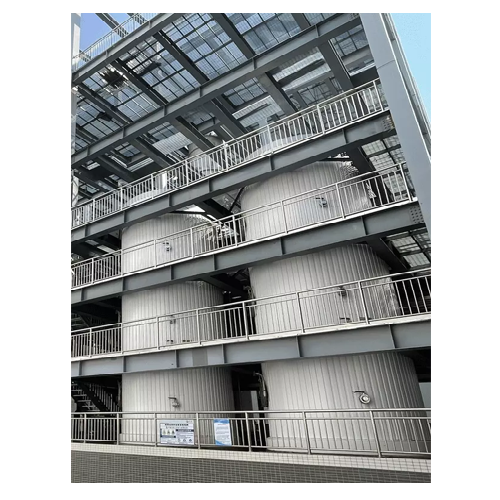

The Sequential Simulated Moving Bed (SSMB) System from Applexion is an industrial chromatography solution designed for the continuous separation and purification of complex liquid mixtures. This system stands out for its ability to achieve high purity and recovery rates, up to 99%, while minimizing resin and footprint requirements. It employs a multi-column setup that facilitates efficient 24/7/365 operations, crucial for industries requiring high throughput, such as food ingredients and pharmaceuticals.

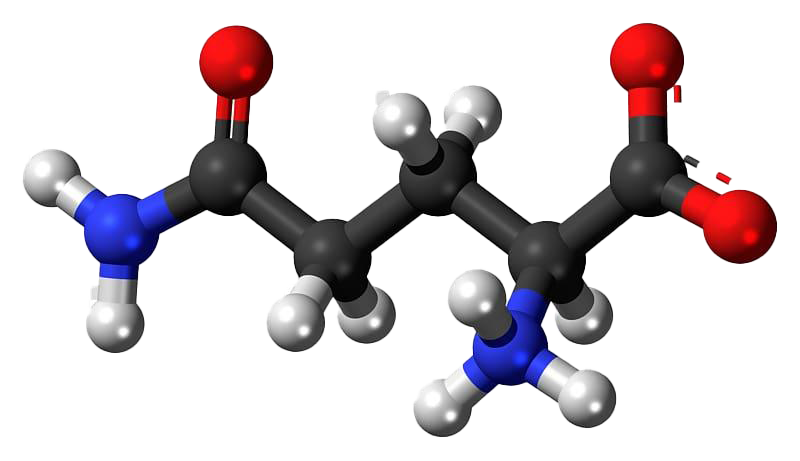

Ideal for producing high-fructose corn syrup, crystalline fructose, and various amino and organic acids, the SSMB technology is particularly suited for bio-based and fermentation-based products. By leveraging advanced PLC automation, the system ensures seamless integration into existing production lines and offers remote monitoring capabilities. Energy efficiency is enhanced through optimized flow distribution, significantly reducing operational costs.

Constructed from materials like stainless steel to withstand corrosion and chemical reactions, it meets industry standards for safety and compliance. The design includes options for CIP (Clean-In-Place) systems, simplifying maintenance, and reducing downtime. Applexion provides extensive customization and engineering support, tailoring configurations to meet specific production needs, ensuring that each setup is optimized for the highest performance and efficiency.

Benefits

- Maximizes productivity with continuous 24/7/365 operation, significantly boosting output for high-demand sectors.

- Achieves high purity levels up to 99%, ensuring superior product quality and reducing waste.

- Lowers operational costs through efficient energy use and reduced resin requirements.

- Integrates seamlessly with existing systems using advanced automation, improving workflow efficiency.

- Complies with industry regulations, ensuring safety and reliability in demanding environments.

- Applications

- Functional ingredients, Amino acids, Organic acids, Industrial products, Oligosaccharides, Food ingredients, Commodity chemicals, Bio-based chemicals, Fermentation-based products, Cellulosic sugars, Sweeteners

- End products

- Lactic acid, Fos (fructooligosaccharides), Crystalline fructose, Hmo (human milk oligosaccharides), Hfcs 55, Hfcs 95, Meg, Hfcs 99, Xylitol, Tryptophan, Methionine, Mannitol, Maltitol, Gos (galactooligosaccharides), Leucine, Citric acid, Glycine, Pdo, Sorbitol, Phenylalanine, Cellulosic sugars

- Steps before

- Pre-treatment, Raw material definition, Lab screening, Resin screening

- Steps after

- Pilot scale validation, Market testing, Post-purification processing, Product distribution

- Input ingredients

- liquid mixture, raw material, effluents, mother liquors

- Output ingredients

- high purity fractions, HFCS 55/95/99, crystalline fructose, high DX glucose, crystalline dextrose, polyols, sorbitol, maltitol, mannitol, xylitol, commodity chemicals, MEG, PDO, glycine, oligosaccharides, FOS, GOS, HMO, cellulosic sugars, organic acids, citric acids, lactic acid, amino acids, tryptophane, phenylalanine, leucine, methionine

- Market info

- APPLEXION is known for their expertise in designing and manufacturing engineered-to-order equipment for the food, beverage, and biotechnology industries, focusing on advanced separation and purification technologies. They are reputed for high-quality, tailor-made solutions.

- Automation

- Fully automated

- Operation Mode

- Continuous 24/7/365

- Eluent Use

- Water-based

- Recovery and Purity

- Up to 99%

- Separation Mechanism

- SMB and SSMB

- Capacity

- High throughput for large-scale processes

- Resin Type

- Ion exclusion, Affinity, Acid retardation, Size exclusion

- Operating Conditions

- Adjustable (concentration, temperature, pH)

- Energy Usage

- Mostly electrical for water/eluent recycling

- Separation Technique

- Sequential Chromatography

- Automation level

- PLC / SCADA / Fully Automated

- Batch vs. continuous operation

- Continuous 24/7/365

- Energy efficiency

- Minimal electrical use for water/eluent recycling

- CIP/SIP

- Green process, no chemicals

- Changeover time

- Quick adaptation to different production requirements

- Cleaning method

- Water as eluent, no chemical effluents

- Integrated steps

- R, D to plant start-up and beyond

- Working mechanism

- Simulated Moving Bed (SMB) / Sequential Simulated Moving Bed (SSMB)

- Machine footprint

- Compact design

- Tank shape

- Column-based

- System configuration

- Multi-column

- Feed method

- Continuous feed

- Discharge method

- Continuous discharge

- Resin type

- Specific for target separation

- Control panel type

- Automated control system

- Operating temperature range

- Varies based on process design

- Control panel type

- Touchscreen / HMI

- System Integration

- Compatible with SCADA / PLC systems

- Resin selection

- Customized based on specific separation needs

- Flow distribution design

- Sequential / Customized

- Column Configuration

- Variable number of columns to suit specific process

- Process monitoring

- Online monitoring with advanced controllers