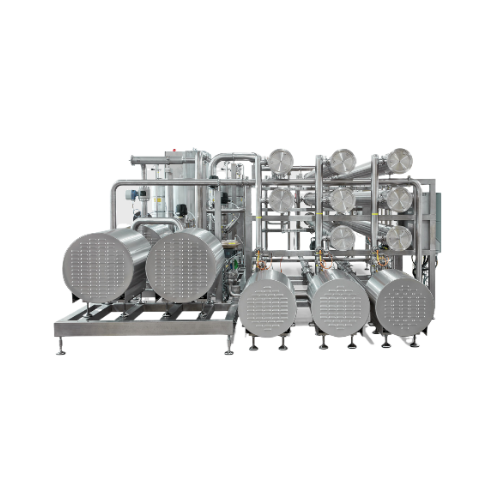

Cip recovery system with membrane filtration

Reduce chemical waste and operating costs by recovering over 90% of spent caustic solutions in your cleaning processes with this advanced membrane filtration unit.

Regenerates and Purifies Caustic Cleaning Solutions

The GEA CIP Recovery Unit with Membrane Filtration is engineered to transform waste management in industries like food, beverage, chemical, and pharmaceutical. Utilizing pH-resistant nanofiltration membranes, it recovers over 90% of spent caustic solutions, minimizing waste and operational costs. This unit integrates seamlessly into existing CIP systems with its plug-and-play design, ensuring easy installation. The system operates at up to 70°C to efficiently regenerate cleaning solutions, making it ideal for continuous high-temperature processes. With a modular setup, it supports scalability and cost-effectiveness. Stainless steel construction ensures durability and corrosion resistance, and it includes an automated PLC-control for streamlined operation. Designed for versatility, the unit caters to caustic soda recovery, protein purification, and more, aligning with sustainability goals by reducing chemical loss and wastewater discharge.

Benefits

- Reduces chemical expenses by recycling over 90% of caustic solutions.

- Minimizes wastewater treatment costs through efficient filtration processes.

- Enhances sustainability by significantly lowering environmental discharge.

- Ensures quick integration with existing systems via plug-and-play design.

- Operates at high temperatures, reducing energy expenses with efficient filtration.

- Applications

- Food, Personal care, Marine, Gas and energy, Beverage, Dairy farming, Refrigeration, Oil, Heating, Environment, Chemical, Pharma, Healthcare, Home, New food, Dairy

- End products

- Wastewater neutralization, Sugar removal, Protein purification, Colorant filtration, Chemical reuse, Energy-efficient heating solutions, Aroma retention, Boiler feed water purification, Safe drinking water, Caustic soda recovery, Rinsing water purification, Detergent recycling, Pharmaceutical filtration, Aroma extraction, Process water recycling, Beer recovery from tank bottoms

- Steps before

- Cleaning, Caustic solution preparation

- Steps after

- CIP solution regeneration, Wastewater neutralization, Water discharge

- Input ingredients

- spent caustic solution, sodium hydroxide solution, impurities, proteins, sugars, colorants, contaminated CIP solution

- Output ingredients

- purified caustic solution, cleaned and regenerated CIP solution, removed impurities, retentate, permeate

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Filtration type

- Nanofiltration / Ultrafiltration

- Regeneration Temperature

- Up to 70°C

- Chemical Composition

- 2-4% Sodium Hydroxide Solution

- Efficiency

- Recover more than 90% caustic solution

- System Design

- Plug, Play

- Modular Design

- Standardized

- Energy Cost Reduction

- High-temperature filtration

- Working mechanism

- Membrane filtration

- Integrated steps

- Ultrafiltration (UF) and Nanofiltration (NF)

- CIP principles

- CIP solution regeneration

- Batch vs. inline flow

- Batch operation

- Automation level

- PLC-controlled

- Energy efficiency

- High-temperature filtration

- Modular design

- Standardized for cost efficiency

- Temperature range

- Up to 70 °C