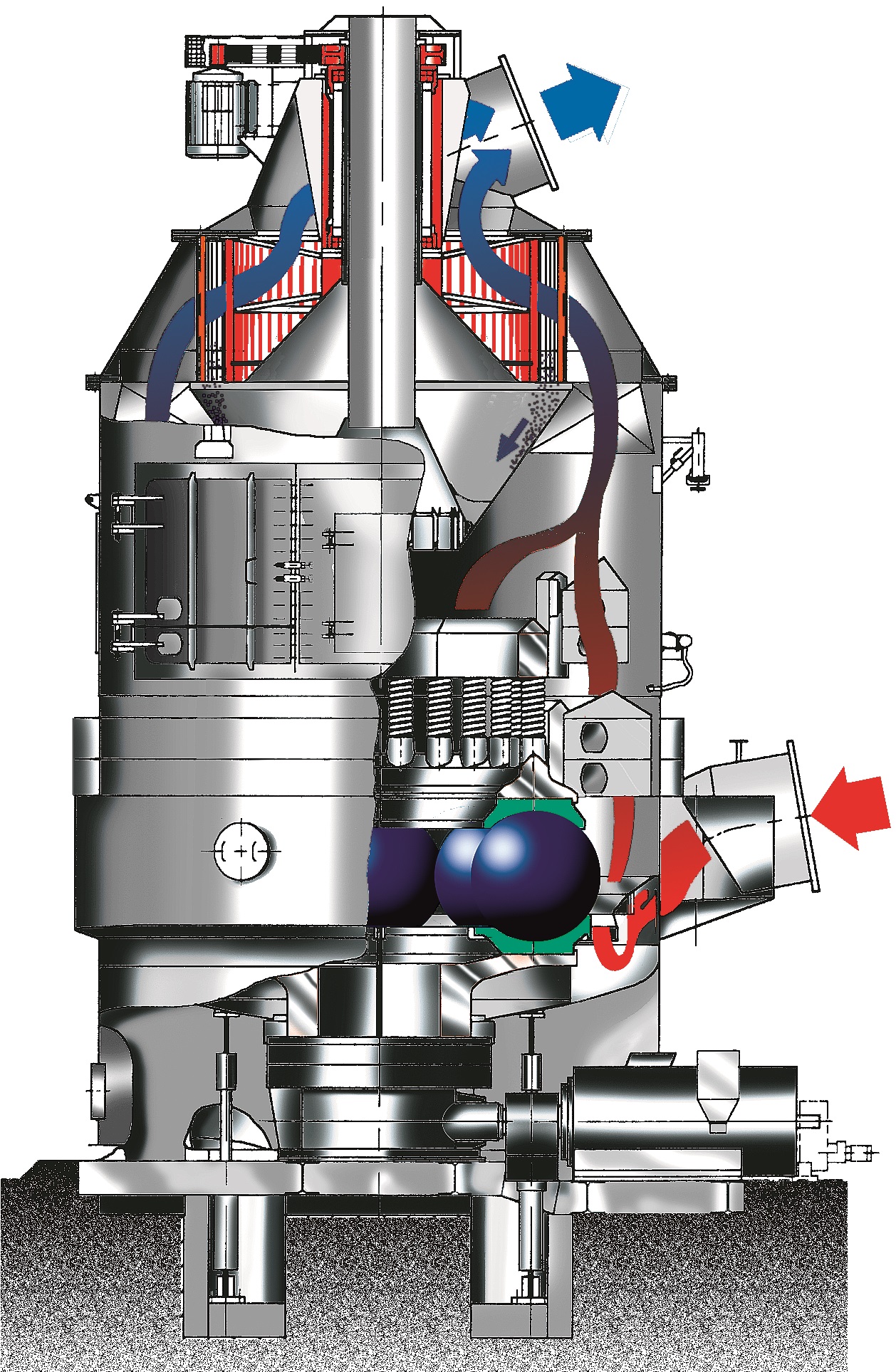

Mill for calcining gypsum

Quality of gypsum and stucco products are highly influenced by the quality of the calcining process employed in production. Consistent grinding, purification, and drying of raw mineral inputs prior to their being entrained in the hot gas flow of the calcining equipment ensures efficient calcining and a resultant high-quality final product.

Grinding, purifying, drying, and calcining from a single piece of equipment

Claudius Peters’ EM Mill is a calcining system for gypsum and stucco with an integrated grinding mill. The mill uses free moving steel balls rather than stationary rollers which ensures uniform fine grinding while avoiding the need for any bearings inside the mill. The grinding system employed requires very little maintenance and has been known to achieve a service life of over 40,000 hours. At the base of the grinding system, a scraper acts on the ball track conveying foreign material out of the mill into the reject box.

The efficiency of the grinding system allows low material time inside the mill enhancing the controllability of the process and ensuring uniform product quality. After sufficient grinding material is entrained in a calcining gas flow of unusually high temperature which yields lower gas volumes and optimal energy consumption. The constant randomized motion of the ball grinding system ensures even and constant distribution of raw gypsum for exposure to the calcining flow.

Benefits

- No bearings inside mill

- Inlet gas temperatures up to 650 C

- Maintenance free grinding elements

- Available in a wide range of capacities up to 80 ton/ hour